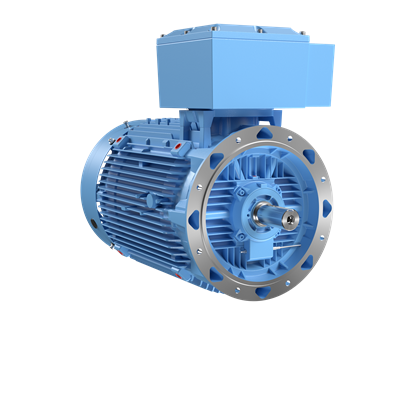

ABB 3GJM283230-BSG 3-Phase Motor - Exd Flameproof

Part Number: 3GJM284210-ADG

Quick Summary

ABB 3GJM283230-BSG is a 3-phase squirrel cage motor designed for explosive atmospheres in mining applications. In challenging environments, equipment downtime and regulatory compliance drive maintenance costs and safety risk, so robust protection matters. This motor delivers Exd flameproof protection, Exdb, IP66, and IC411 insulation, enabling safe operation in gas and dust hazards. With an IE2 efficiency rating, it optimizes energy use across full-load and partial-load conditions, reducing operating costs over the life of the motor. Manufactured in Finland, it uses a cast-iron frame, 6313/C3 bearings, and IMB5 IM3001 alignment for durability. Designed for top-entry installation and 1000 m altitude at 40 C ambient, it supports mining conveyors and material handling with high uptime.

Product Information

ABB Type Designation

M3JM 280SMA 8

Invoice Description

M3JM 280SMA 8

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015230

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 91.7 % | Partial Load (75%) 91.7 % | Partial Load (50%) 90.2 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

8

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

280

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB3 IM1001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

626 kg

Gross Weight

646 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Exd flameproof protection and IP66 enclosure mitigate ignition risks and dust ingress, translating to safer underground and surface installations and reduced compliance overhead. In mining environments where gas or dust hazards exist, the motor’s sealing and flameproof joints minimize the chance of costly shutdowns, gear damage, and fines. This design supports continuous operation of conveyors, crushers, and material-handling systems, even in hot, dusty zones where reliability translates directly into production uptime and maintenance planning. IE2 efficiency delivers tangible energy savings across both full-load and partial-load conditions. With Full Load at 94.1% and Partial Load results of 94.7% at 75% and 94.5% at 50%, energy costs for long-running lines are reduced while maintaining consistent torque and speed. This performance aligns with energy-management programs and regulatory targets, helping you meet sustainability goals without sacrificing throughput in ore processing and bulk-material handling applications. Rob rust-robust mechanicals—cast iron frame 280, bearings 6313/C3, and IM B5 IM3001 alignment—deliver durability in shock-prone mining environments. Top-entry terminator box simplifies field wiring, while precise tolerances support reliable lubrication and bearing life. The 6-pole design reduces speed variability and improves stall resilience, making it a stable backbone for large driven equipment like crushers and mills. Environmental and regulatory compatibility—Altitude up to 1000 m, ambient temperature 40 °C, IC411 insulation, and Exdb Exd protections ensure performance in hot, high-altitude sites. Finland origin signals consistent manufacturing quality and traceability, while IP66 sealing provides long-term protection against moisture and ingress. These characteristics are especially valuable for underground installations and remote facilities where service visits are infrequent. Duty and installation—S1 continuous duty and a 1 piece minimum order quantity align with project planning and stock strategies. The motor is designed for straightforward mounting with standard electrical cabinets, enabling rapid deployment in new mines or refurbishment programs and reducing total project lead times.

Get a Quick Quote for a ABB 3GJM284210-ADG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM284210-ADG?

Enquire Now

FAQs

Ensure Exd flameproof protection is properly engaged and cable glands are rated for hazardous zones. Use the top-entry terminator box for wiring access, follow the 1000 m altitude and 40 °C ambient guidelines, and verify IP66 seals and Exdb/Exd certifications. Use compatible mounting hardware for a 280 frame and 6-pole configuration, and consult ABB installation drawings for correct alignment and bearing lubrication intervals to maximize uptime.

IE2 efficiency is specified at Full Load 100% 94.1%, with Partial Load values of 94.7% at 75% and 94.5% at 50%. Higher efficiency under typical mining loads reduces electrical losses, lowers energy bills, and improves total cost of ownership over the motor’s life, especially in long-running conveyors and processing lines where duty cycles are continuous.

Yes. The motor’s 6-pole design, IMB5 IM3001 mounting, 280 frame, and high IP66/IP protection ratings make it well-suited for conveyors and material-handling equipment in challenging environments. Its Exd/Exdb flameproof protections meet hazardous-area requirements, and the 1000 m altitude capability supports high-elevation sites common in mining operations.

The motor features Exd flameproof protection with Exdb, IP66 enclosure, and IC411 insulation class, ensuring compliance with hazardous-area and dust-heavy environments. It operates under S1 continuous duty, has a six-pole configuration, and maintains safe operation across a wide range of mining conditions. These certifications support regulatory compliance and safer installation practices.

Durable cast-iron construction, 6313/C3 bearings, and IMB5 IM3001 alignment deliver extended bearing life and reduced maintenance cycles. The IE2 efficiency contributes to ongoing energy savings, lowering operating costs. With Finland-made quality and a robust enclosure, this motor offers long service life, fewer unplanned outages, and a favorable return on investment for mining fleets.