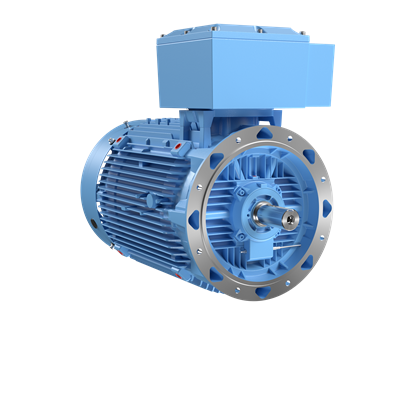

ABB 3GJM284210-ASG 3-Phase motor - Exdb Flameproof

Part Number: 3GJM284210-ASG

Quick Summary

ABB 3GJM284210-ASG is a 3-phase squirrel cage motor designed for demanding mining and heavy-industry drives. In the field, reliability under harsh conditions and compliance with safety and energy standards are constant concerns. This model combines Exdb flameproof protection, IP66 enclosure, and IE2 efficiency with tough insulation (ICLF) and a cast-iron frame, delivering safe operation in hazardous zones. The motor's 8-pole design supports stable torque and efficient speed control, even when powered through drives, while the Top terminator box simplifies installation. For procurement teams, the result is lower risk, reduced downtime, and predictable operating costs in challenging environments.

Product Information

ABB Type Designation

M3JM 280SMA 8

Invoice Description

M3JM 280SMA 8

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015230

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 91.7 % | Partial Load (75%) 91.7 % | Partial Load (50%) 90.2 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

8

Two Speed Motor

No

Type of Duty

S1

Voltage Code

S

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

280

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB3 IM1001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

626 kg

Gross Weight

646 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Exdb flameproof protection is more than a certification—it’s a safety baseline for mining and other hazardous environments. This yields a clear business impact: reduced risk to personnel and equipment, lower incident-related downtime, and easier regulatory compliance when installing motors in volatile atmospheres. The IP66 enclosure and cast-iron frame further minimize ingress, dust, and moisture ingress, translating to longer bearing life and fewer unplanned maintenance cycles in harsh plants. IE2 efficiency delivers tangible energy savings during extended operations, with 8-pole design enabling smoother starts and better torque control when paired with variable frequency drives (VFDs). The IC411 insulation and robust IMB3 IM1001 mounting provide thermal reliability under continuous duty (S1), supporting predictable performance in mining conveyors and pumps. Top terminator box access simplifies installation, wiring, and future servicing while reducing commissioning time. Overall, the design aligns safety, reliability, and lifecycle cost improvements with the realities of tough industrial environments.

Get a Quick Quote for a ABB 3GJM284210-ASG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM284210-ASG?

Enquire Now

FAQs

Installation in hazardous areas requires attention to Exdb flameproof compliance and IP66 protection. Use the top- located terminator box for wiring, ensure cable glands meet enclosure rating, and position for adequate ventilation. The motor is rated for up to 1000 m altitude and 40 °C ambient, with IMB3/IM1001 mounting and 8-pole operation for smooth starts.

Yes. The IEC IE2 efficiency data shows full-load efficiency at 91.7%, with similar performance at partial loads (75% and 50%). Coupled with S1 continuous duty and Exdb protection, the motor delivers reliable, energy-conscious operation in mining and heavy-duty processes, while maintaining thermal stability under sustained runs. It integrates with standard VFDs for controlled start-up.

Absolutely. The Exdb flameproof protection combined with IP66 ingress protection is designed for mining environments with dust, moisture, and methane hazards. It carries robust construction, fireproof insulation (ICLF), and a UL/IECEx compatible design. When installed with appropriate guarding and safe operating procedures, it supports continuous mining operations while meeting industry standards.

Key mechanicals include a Cast Iron frame (Frame Size 280) with 6316/C3 bearings and IM class IMB3 IM1001, plus a top terminator box for easy access. The 626 kg net and 646 kg gross weight, along with a durable 280 mm frame, simplify alignment, vibro-damping, and bearing life, reducing maintenance downtime in harsh plant environments.

Choosing IE2 efficiency and an 8-pole architecture lowers energy bills during long runs and reduces cooling loads. The robust cast iron frame and Exdb/IP66 enclosure minimize maintenance intervals in mining sites. Although initial price may be higher, lifecycle cost is reduced through fewer spare-part needs and extended bearing life in harsh conditions.