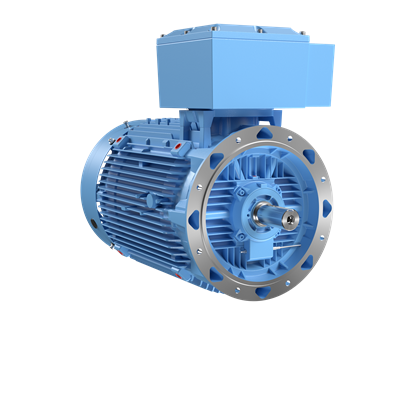

ABB 3GJM284230-BDG 3-Phase Squirrel Cage Motor - Exd IP66 IE2

Part Number: 3GJM284230-BDG

Quick Summary

ABB 3GJM284230-BDG 3-Phase Squirrel Cage Motor is engineered for rugged, flameproof mining and heavy industry drives. In challenging environments, downtime and safety risk rise when equipment isn’t explosion-protected or weatherproof; this motor mitigates that with robust Exd protection and a sealed IP66 enclosure. It carries Exdb flameproof certification, IP66 ingress protection, and IC411 insulation class, plus IE2 efficiency, delivering reliable performance and compliant operation. For system integrators and procurement teams, this motor combines a rugged enclosure with high efficiency to reduce maintenance costs and extend service life. By pairing top-side termination, a heavy cast-iron frame, and reversible rotation, it simplifies installation and reduces total cost of ownership in hazardous locations.

Product Information

ABB Type Designation

M3JM 280SMC 8

Invoice Description

M3JM 280SMC 8

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015230

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 92.4 % | Partial Load (75%) 92.4 % | Partial Load (50%) 91.4 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

8

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

280

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB5 IM3001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

746 kg

Gross Weight

766 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Exdb flameproof protection provides a safer solution in hazardous zones, reducing the risk of ignition and enabling compliant operation in mining and other explosion-risk environments. This protection translates to lower downtime and stronger worker safety while maintaining continual operation under demanding duty cycles in harsh climates. IP66 enclosure guarantees dust-tight integrity and water ingress protection, safeguarding winding integrity and extending service life in dusty or wet industrial facilities. Insulation class ICLF supports reliable performance at ambient temperatures up to 40 °C, helping meet continuous operating requirements in hot sites and reducing thermal-related failures. The 280 frame size in cast-iron housing, paired with 6316/C3 bearings and IMB5 IM3001 alignment, delivers durability, vibration resistance, and long bearing life for arduous, continuous operation. An 8-pole design with IE2 efficiency yields predictable, energy-saving performance with Full Load (100%) 92.4% and Partial Load (75%) 92.4%, minimizing energy costs across shifts. Reversible rotation and a top termination box simplify installation and retrofits in constrained spaces, while the option to source from Finland FI ensures a robust supply chain with reliable lead times. This model is well-suited for hazardous-area conveyors, heavy-duty pumps, and other mining motor applications where uptime and compliance matter most.

Get a Quick Quote for a ABB 3GJM284230-BDG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM284230-BDG?

Enquire Now

FAQs

This motor features a top termination box and an IMB5 IM3001 mounting class, designed for straightforward installation in constrained spaces. With an 8-pole design (frame 280) and reversible rotation, alignment with standard baseplates and couplings is simplified. Ensure Exd zoning compliance, IP66 enclosure integrity, and appropriate cable glands for hazardous areas, and verify that the supply matches Voltage Code D and ambient conditions up to 40 °C at up to 1000 m altitude.

The motor is rated IE2 with Full Load efficiency of 92.4%. At partial loads, specified values show 92.4% at 75% and 91.4% at 50% load, ensuring energy efficiency across operating points. These figures support energy-saving strategies in continuous duty applications and help reduce operating costs over the motor’s lifecycle in demanding environments.

Yes. The motor carries Exdb flameproof protection and an IP66 enclosure, enabling safe operation in hazardous zones such as mining and other explosive atmospheres. Insulation class ICLF supports endurance under elevated ambient temperatures, and the unit’s design aligns with continuous-duty S1 operation, assisting with regulatory compliance and safety standards in tough environments.

Key compliance features include Exdb flameproof protection, IP66 ingress protection, and insulation class ICLF for reliable coil insulation at higher ambient temperatures. The cast-iron frame (280) with 6316/C3 bearings and IMB5 IM3001 mounting provides robust mechanical durability. The motor also supports 8-pole operation and reversible rotation, making it adaptable for bidirectional drives while maintaining safety standards in mining applications.

The rugged cast-iron frame, durable bearings, and flameproof protection reduce maintenance frequency in harsh environments, delivering longer service intervals and lower total cost of ownership. IP66 protection minimizes ingress-related faults, while IEC IE2 efficiency lowers energy usage across shifts. Top termination and modular mounting simplify inspections and replacements, supporting predictable maintenance planning in continuous-duty scenarios.