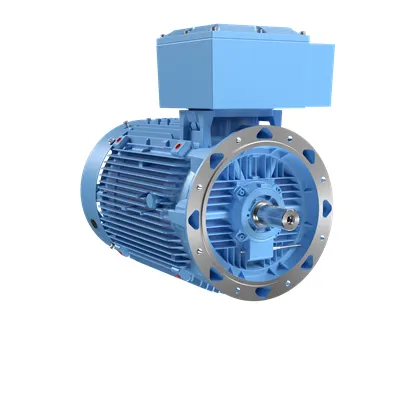

ABB 3GJM285230-ADG 3-Phase Squirrel Cage Motor - Exdb

Part Number: 3GJM285230-ADG

Quick Summary

ABB 3GJM285230-ADG is a 3-phase squirrel cage motor designed for demanding mining and heavy industry applications. Engineers often grapple with safety compliance, uptime guarantees, and harsh-environment reliability when selecting motors for hazardous zones. This unit combines Exdb flameproof protection with IP66 sealing and IC411 insulation to withstand challenging conditions while maintaining continuous operation. With a 10-pole, cast-iron frame and IMB3 IM1001 mounting class, it supports straightforward installation and long service life. For procurement teams prioritizing regulatory compliance, maintenance predictability, and total cost of ownership, this motor delivers a clear path to reduced downtime and dependable performance. Its altitude tolerance and ambient temperature rating further enable stable operation across remote or harsh sites, supporting broader asset strategies and lifecycle planning.

Product Information

ABB Type Designation

M3JM 280SMC 10

Invoice Description

M3JM 280SMC 10

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015290

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 92.9 % | Partial Load (75%) 92.7 % | Partial Load (50%) 91.2 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

10

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

280

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB3 IM1001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

846 kg

Gross Weight

866 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature → Business Impact → Application: The Exdb flameproof protection combined with IP66 sealing minimizes ignition risks in hazardous zones, reducing safety incidents and compliance overhead while enabling continuous mining operations. This translates to lower maintenance costs and higher overall equipment effectiveness (OEE) on belt lines and shaft applications. Feature → Business Impact → Application: The 10-pole, 280 frame with a cast-iron enclosure provides robust mechanical integrity for heavy-duty loads and shock resilience in demanding environments such as mine haulage and processing plants. This supports long service intervals and reduces replacement downtime, ideal for stand-alone drives or plant-wide motor upgrades. Feature → Business Impact → Application: Insulation Class ICLF and IC411 rating ensure stable electrical performance at 40 °C ambient and up to 1,000 m altitude, delivering reliable torque characteristics for continuous S1 operation under variable loading. Feature → Business Impact → Application: Top-entry termination and IMB3 IM1001 mounting compatibility enable faster on-site commissioning and easier retrofits in existing facilities, decreasing installation time and risk of wiring errors. Feature → Business Impact → Application: The motor’s 6316/C3 bearings and cast-iron frame support rugged life-cycle performance, reducing unscheduled maintenance and enabling predictive maintenance programs in underground or above-ground mining operations. Feature → Business Impact → Application: The combination of EX-protection, IP ratings, and robust mechanical design helps ensure compliance with ATEX/IECEx requirements, enhancing safety case documentation for project approvals and asset registers. Feature → Business Impact → Application: The unit’s 85015290 tariff classification and Finland-origin sourcing give procurement teams clearer logistics planning and supply chain resilience for global projects requiring traceability and consistent lead times. Feature → Business Impact → Application: The designation M3JM 280SMC 10 and Product Type alignment support standardized replacement strategy across fleets of flameproof motors, simplifying spares management and training for maintenance personnel.

Get a Quick Quote for a ABB 3GJM285230-ADG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM285230-ADG?

Enquire Now

FAQs

This motor uses a 280 frame with Cast Iron housing and bearing 6316/C3 on IMB3 IM1001 support. Installation is optimized with a Top terminator box and a robust IMB3 mounting footprint, enabling straightforward alignment, secure cable routing, and reliable heat dissipation in hazardous locations.

Yes. It features Exdb flameproof protection and IP66 ingress protection, suitable for hazardous environments. Insulation class ICLF and IC411 provide reliable electrical performance at elevated temperatures, while the 1,000 m altitude rating supports operation in high-altitude sites.

The motor is a 3-phase IE2-equivalent class device with a voltage code D. When pairing with VFDs, ensure the drive is rated for Ex-d use and that motor terminal box access remains sealed. Start-up transients should be managed to preserve bearing life and limit torque shocks on heavy loads.

Absolutely. With Exdb flameproof protection, IP66 protection, 10 poles for robust starting torque, and a cast-iron frame, it is well-suited for mining, cement, and other heavy industries where hazardous zones and demanding duty cycles (S1) are common.

Implement a bearing inspection schedule for 6316/C3 bearings, monitor vibration and temperature, and perform lubrication per ABB guidance for IMB3 IM1001 assemblies. The rugged frame and protective features reduce unplanned outages, delivering a favorable total cost of ownership over long asset lifecycles.