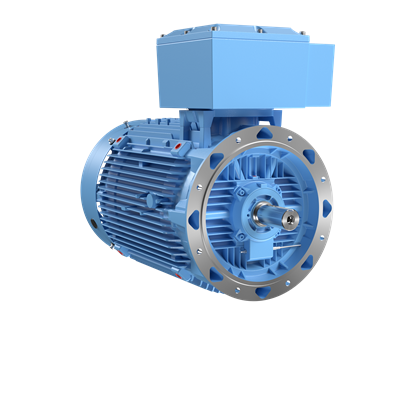

ABB 3GJM311210-BEG 3-Phase squirrel cage motor - Exdb IP66

Part Number: 3GJM311210-BEG

Quick Summary

ABB 3GJM311210-BEG is a 3-phase squirrel cage motor designed for demanding mining and hazardous-area applications. Operators face uptime pressures from explosion hazards, high ambient temperatures, and remote service challenges. This motor delivers IC411 insulation, IP66 enclosure, and Exdb flameproof protection, plus IE2 efficiency. Used in mining and other hazardous environments, it supports reliable performance, compliance, and low lifecycle costs. With a 315 frame and a 2-pole configuration, it delivers robust torque characteristics for heavy-load starts. Designed for top-terminal-box installation and straightforward mounting, it simplifies integration in constrained plant spaces. Its Exdb protection reduces flame-related risks and supports regulatory compliance for mining projects worldwide.

Product Information

ABB Type Designation

M3JM 315SMA 2

Invoice Description

M3JM 315SMA 2

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 94.9 % | Partial Load (75%) 94.2 % | Partial Load (50%) 92.7 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

E

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

315

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB5 IM3001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

1002 kg

Gross Weight

1022 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100 | 39120000

Exdb flameproof protection and IP66 enclosure provide safe operation in explosive atmospheres and dusty environments, reducing ignition risks and unplanned downtime. The combination is ideal for mining, tunneling, and processing plants where hazardous-location compliance is mandatory. The rugged cast-iron frame further enhances durability in harsh surroundings, supporting longer service life and lower replacement costs. IE2 efficiency, with full-load 94.9% and partial-load performance around 94.2% to 92.7%, delivers measurable energy savings across the S1 duty cycle. Lower input losses translate into cooler windings, reduced cooling requirements, and longer insulation life. In continuous mining and material-handling applications, this reduces operating costs and improves equipment availability. Cast iron frame, 315 frame size, and bearings 6316/C3 provide structural rigidity and durability under heavy starts. The IMB5 IM3001 mounting class supports reliable belt-drive or gear-motor configurations, simplifying installation and enabling quick spare-part swaps. This robustness is essential for conveyors, pumps, and fans that operate under load in tough environments. Altitude up to 1000 m and ambient temperature up to 40 °C are accounted for in the motor's thermal design, ensuring consistent torque and protection in elevated sites. Insulation class ICLF, IC411, along with Exdb and IP66, align with hazardous-area standards, streamlining procurement and compliance documentation. Top terminator box location speeds wiring during commissioning and service. Two-pole, single-speed S1 operation delivers reliable, constant torque in a compact footprint, while reversible rotation supports versatile installation. The motor is not made-to-order, with a minimum 1 piece order, enabling rapid fulfillment for project runs. These features simplify maintenance planning and inventory management across mining and industrial plants.

Get a Quick Quote for a ABB 3GJM311210-BEG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM311210-BEG?

Enquire Now

FAQs

This motor uses Exdb flameproof protection and an IP66 enclosure, so install with hazardous-area rated wiring and inspection practices. Plan for a top-terminal-box configuration, 315 frame mounting, and operation within 1000 m altitude and 40 °C ambient. Ensure compatible control gear and certified components are used to maintain compliance during commissioning and routine service.

IE2 efficiency yields lower input losses, contributing to energy savings across the duty cycle. With full-load efficiency near 94.9% and high partial-load performance, the motor runs cooler and reduces cooling demands, which translates to lower electricity bills and improved plant availability in continuous mining and material-handling operations.

Yes. It combines Exdb flameproof protection, IP66 enclosure, IC411 insulation, and a robust 315 frame with 2-pole design. Rated for S1 duty and 1000 m altitude at 40 °C ambient, it supports reliable operation in mining, tunneling, and other hazardous environments while meeting essential regulatory requirements.

Made To Order is No, and the minimum order quantity is 1 piece with an order multiple of 1. This supports rapid fulfillment for ongoing projects and simplifies procurement. Typical lead times depend on stock and destination, but the standard configuration is designed for quick integration with existing plant drives.

Expect improved uptime due to rugged cast-iron construction, Exdb and IP66 protection, and low maintenance needs. IE2 efficiency reduces energy costs, while the bearings and IM class support long service life under heavy starts. Overall, this motor lowers lifecycle costs and strengthens plant reliability in hazardous environments.