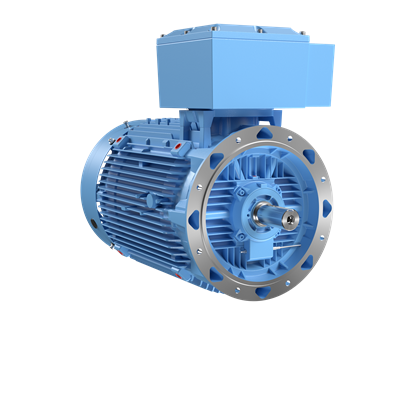

ABB 3GJM311210-BSG 3-Phase Squirrel Cage Motor - Exdb

Part Number: 3GJM311210-BSG

Quick Summary

ABB 3GJM311210-BSG 3-Phase Squirrel Cage Motor is engineered for demanding mining and heavy industrial applications, delivering robust power with flameproof protection. In hazardous environments, downtime and safety concerns drive the need for rugged construction and reliable protection. This model provides IP66 ingress protection, Exdb flameproof protection, and ICFL insulation, with IE2 efficiency to cut energy costs. Combined with a cast iron frame, bearing 6316/C3, and a top-entry terminator box, it supports straightforward installation and long service life. These features align with mining and process industries seeking reliable performance, safe operation, and predictable procurement for capital projects.

Product Information

ABB Type Designation

M3JM 315SMA 2

Invoice Description

M3JM 315SMA 2

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 94.9 % | Partial Load (75%) 94.2 % | Partial Load (50%) 92.7 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 93.3 % | Partial Load (75%) 92.4 % | Partial Load (50%) 90.3 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

S

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

315

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB5 IM3001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

1002 kg

Gross Weight

1022 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100 | 39120000

Feature → Business Impact → Application: Flameproof Exdb protection enhances safety and regulatory compliance in explosive atmospheres, reducing the risk of ignition and costly shutdowns while supporting ATEX/IECEx aligned operations. This translates to lower total cost of ownership for mining conveyors and heavy-duty processing lines. Application: hazardous area motors suitable for mining and metal processing sites. Feature → Business Impact → Application: IP66 ingress protection paired with a rugged cast iron frame boosts durability in dusty, wet environments, lowering maintenance frequency and extending service intervals. Application: surface and underground conveyors, crushers, and material handling in harsh plant floors. Feature → Business Impact → Application: IE2 efficiency (Full Load 94.9% at 50 Hz) delivers measurable energy savings and compressor-free operation, reducing operating costs across shift cycles. Application: continuous duty processes and pump drives in remote locations. Feature → Business Impact → Application: 2-pole design with 315 frame and 1000 m altitude tolerance supports high-start torque and stable performance in variable elevations. Application: hoisting and winch systems in elevated mining facilities. Feature → Business Impact → Application: Bearing 6316/C3 and IMB5 IM3001 construction enable heavy-load handling with lower vibration and longer life, decreasing spare parts consumption. Application: belt drives and mills with demanding load profiles. Feature → Business Impact → Application: Top terminator box and compatibility with standard drives streamline installation and retrofit projects, enabling faster commissioning and easier field maintenance. Application: retrofits and new-builds in hazardous industrial settings.

Get a Quick Quote for a ABB 3GJM311210-BSG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM311210-BSG?

Enquire Now

FAQs

For safe, compliant installation in explosive environments, ensure Exdb flameproof protection is maintained, connect via the top-entry terminal box, and secure the cast iron 315 frame to vibration-friendly bases. Use proper gland seals and ATEX/IECEx guidance to maintain IP66 integrity and insulation performance (ICLF). Ensure mounting is level and within the 1000 m altitude and 40 °C ambient limits for reliable cooling and long life.

IE2 efficiency translates to lower energy consumption under full-load and partial-load conditions. With full-load efficiency around 94.9% at 50 Hz, you’ll see reduced energy bills over the motor’s life, especially in continuous-process and high-duty-cycle applications. This also correlates with cooler running temperatures, potentially extending bearing life and reducing auxiliary cooling requirements.

Yes. The motor’s Exdb flameproof protection and IP66 rating are specifically designed for hazardous locations, including mining conveyors and processing lines. The 315 frame, 2-pole design, and robust IMB5 IM3001 construction support high-start torque and reliable operation under heavy loads, while the 1000 m altitude tolerance ensures performance across varied mining elevations.

This motor features Exdb flameproof protection, IP66 ingress protection, and ICFL insulation suitable for hazardous area installations. While CE marking specifics aren’t listed here, the Exdb designation aligns with ATEX/IECEx compliance, and IC411-like insulation class indicates suitability for demanding ambient conditions. Always verify local regulatory acceptance for your project scope.

The 6316/C3 bearings and cast iron frame, combined with sealed Exdb protection and IP66, reduce maintenance frequency and extend service life in dusty, wet sites. ROI benefits come from energy savings (IE2), lower downtime risk, and fewer spare-part interventions. Expect longer intervals between bearing reseals and easier field servicing due to the top-entry terminator box.