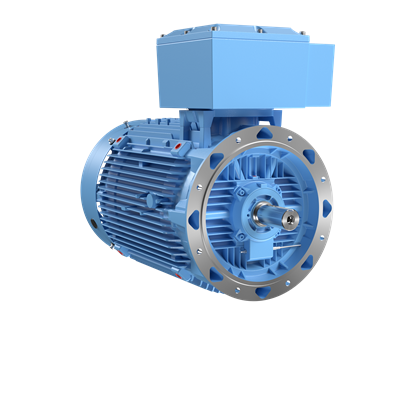

ABB 3GJM311220-AEG 3-Phase Squirrel Cage Motor - Exd

Part Number: 3GJM311220-AEG

Quick Summary

ABB 3GJM311220-AEG 3-Phase Squirrel Cage Motor is built for reliable, explosion-protected operation in demanding mining and industrial environments. This motor addresses the common pain point of balancing safety with uptime, delivering robust performance where hazardous atmospheres are present. It carries critical certifications and ratings that matter in the field, including Exd flameproof protection, Exdb explosion protection, and IP66 enclosure, plus IC411 insulation. With a 315 frame in cast iron, it withstands tough thermal and mechanical conditions while maintaining consistent output. The motor also aligns with IE2 energy efficiency targets, supporting lower operating costs and improved lifecycle economics for engineered systems and maintenance planning.

Product Information

ABB Type Designation

M3JM 315SMB 2

Invoice Description

M3JM 315SMB 2

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 95.1 % | Partial Load (75%) 94.8 % | Partial Load (50%) 93.6 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

E

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

315

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB3 IM1001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

962 kg

Gross Weight

982 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Exd/Exdb flameproof protection reduces ignition risk in hazardous environments, delivering regulatory compliance and lower downtime in mining and processing facilities. This translates to safer startup and reduced insurance exposure, enabling production teams to operate with confidence in explosive atmospheres. In practice, installations near dusty conveyors and underground equipment benefit from proven flameproof performance that minimizes risk during routine maintenance and emergency shutdowns. The business impact is clear: safer operations, fewer incident-driven outages, and improved asset utilization in mining corridors and refineries. Applications include underground conveyors, ore crushers, and pump stations where explosion protection is mandatory and downtime is costly.

Get a Quick Quote for a ABB 3GJM311220-AEG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM311220-AEG?

Enquire Now

FAQs

For hazardous environments, install with Exd flameproof protection and a suitable Exdb variant as specified. Ensure the termination box is accessible from the top and that the motor is mounted on a compatible base to maintain alignment. Verify cable glands and grounding are compliant with ATEX/IECEx guidelines and maintain adequate clearance for heat dissipation in a dust-prone, high-temperature setting.

IE2 performance is rated at Full Load (100%) around 95.1% efficiency, with Partial Load (75%) near 94.8% and Partial Load (50%) near 93.6%. These figures translate to meaningful energy savings during steady-state operation and during variable loads typical of conveyors, pumps, and fans in mining and industrial applications.

Yes. The motor features Exd/Exdb explosion protection, IP66 enclosure, and a rugged cast-iron frame, making it well-suited for underground and surface mining equipment, crushers, and pump stations where hazardous atmospheres and tough environments are present.

Key certifications include Exd flameproof protection and Exdb explosion protection, IP66 enclosure, IC411 insulation class, and ATEX/IECEx compliance potential. The motor also meets industrial standards for heavy-duty use and is designed for operations up to 1000 m altitude at 40 °C ambient.

The high IE2 efficiency reduces energy costs over the motor’s life, while rugged cast-iron construction and IP66/Ex protection minimize unplanned downtime. Maintenance focuses on bearing checks (6316/C3) and periodic insulation inspections, with longer service intervals in harsh climates, improving uptime and overall ROI for mining or heavy industry projects.