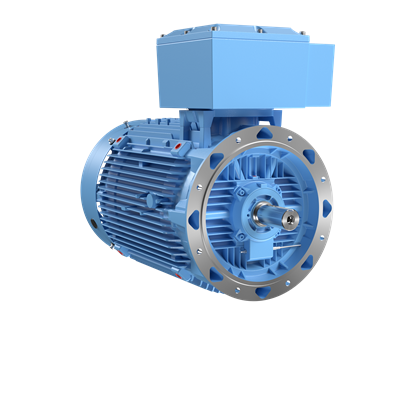

ABB 3GJM311220-ASG 3-Phase squirrel cage motor - Exdb IP66 IC411 IE2

Part Number: 3GJM311220-ASG

Quick Summary

ABB 3GJM311220-ASG is a 3-phase squirrel cage motor for demanding mining and rugged industrial applications. In hazardous or dusty environments, uptime and safety are critical, and ordinary motors struggle with protective seals, electrical clearance, and cooling. This motor combines Exdb explosion protection, IP66 sealing, and IC411 insulation considerations to deliver compliant operation and long service life. Designed for continuous operation (S1) at 40 °C ambient and up to 1000 m altitude, it also delivers energy-efficient performance with IE2 efficiency ratings. With a 315 frame in cast iron and a top-termination box, it simplifies installation, reduces maintenance cycles, and speeds integration into safety-critical systems.

Product Information

ABB Type Designation

M3JM 315SMB 2

Invoice Description

M3JM 315SMB 2

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 95.1 % | Partial Load (75%) 94.8 % | Partial Load (50%) 93.6 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 94.1 % | Partial Load (75%) 93.5 % | Partial Load (50%) 91.7 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

S

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

315

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB3 IM1001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

962 kg

Gross Weight

982 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature Exdb explosion protection → Business Impact Reduced risk of ignition in hazardous zones; compliance with mining and process plant safety standards; Application mining conveyors, chemical processing lines. This enables safer operation and easier regulatory approval. Feature IP66 enclosure → Business Impact Superior dust and water ingress protection; longer bearing life in washdown environments; Application offshore and underground facilities, lift systems. Feature IC411 insulation → Business Impact Higher insulation reliability under demanding temperatures; reduced electrical losses and longer winding life; Application high-temperature, dusty environments. Feature IE2 efficiency data across 50 Hz and 60 Hz → Business Impact Lower energy costs and improved sustainability; predictable operating expenses for continuous duty; Application mineral processing, cement, and metal forming. Feature 315 frame cast iron construction with bearing 6316/C3 → Business Impact Robust mechanical endurance and easy replacement parts; Installation compatibility with standard IEC motor mounts; Application heavy-duty conveyors and pumps. Feature IMB3 IM1001 class and top termination box → Business Impact Simplified maintenance and terminal access; reduced commissioning time; Application plant shutdown minimization and faster integration. Feature Duty S1, 2-pole high speed → Business Impact Continuous operation with high torque characteristics; reliable performance under peak loads; Application fans, hoists, and centrifuges in hazardous areas.

Get a Quick Quote for a ABB 3GJM311220-ASG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM311220-ASG?

Enquire Now

FAQs

ABB 3GJM311220-ASG uses a standard 315 frame and cast iron construction, designed for IEC mounting with a top termination box for simplified wiring and quick field routing. Its Exdb protection class makes it suitable for hazardous areas, meeting typical mining and chemical processing safety requirements. When planning installation, verify terminal box access, ensure suitable cable entries, and confirm clearance for a 315 frame footprint to maintain serviceability and compliance.

At 50 Hz, the motor delivers IE2 full-load efficiency around 95.1% and partial-load values near 94.8% at 75% and 93.6% at 50%. At 60 Hz, IE1 compliance applies with ~94.1%/full-load efficiency and roughly 93.5%/91.7% at 75%/50% load. These figures translate to noticeable reductions in electrical energy consumption, lower operating costs over the motor’s life, and improved thermal performance in continuous duty environments.

Yes. The M3JM 315SMB 2 designation combined with Exdb explosion protection and IP66 sealing makes it well-suited for mining, underground works, and other hazardous area installations. Its 2-pole high-speed design supports demanding torque at start-up, while the S1 duty cycle ensures reliable continuous operation. Its insulation class IC411 and endurance-certified bearings further support long service life in tough environments.

The motor includes Exdb explosion protection, IP66 ingress protection, and IC411 insulation. It is built for continuous service with S1 duty in hazardous zones, and it carries industrial-grade components such as a 315 frame, cast iron housing, and top-termination box for safe and compliant field installation. These features help meet mining, process plant, and regional electrical safety standards without extensive retrofits.

Maintenance benefits come from a robust cast iron frame, durable bearings (6316/C3), and a top-termination box for easier electrical checks. The IE2 efficiency reduces energy costs over time, improving total cost of ownership in continuous-duty operations. Expected ROI improves with lower maintenance downtime, fewer replacement parts, and reliable performance in hazardous environments such as mining and chemical plants.