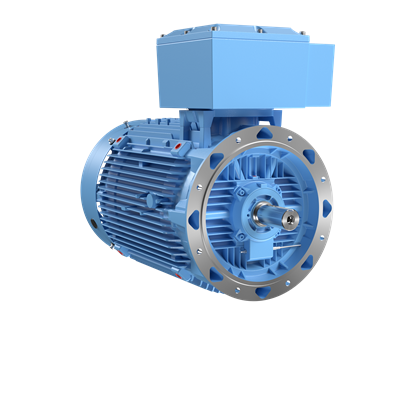

ABB 3GJM311410-ASG 3-Phase Squirrel Cage Motor - Exdb Flameproof

Part Number: 3GJM311410-ASG

Quick Summary

3GJM311410-ASG is a 3-phase squirrel cage motor designed for hazardous environments and mining applications. This solution addresses downtime and reliability challenges by delivering robust protection and long life in demanding conditions. Key certifications include Exdb flameproof protection for explosion-prone areas, IP66 ingress protection against dust and water, and IC411 insulation with IE2 efficiency for reliable performance at altitude up to 1000 meters. The combination of rugged cast iron construction, top terminator box access, and a 315 frame supports easy installation and maintenance in real-world plant layouts. Used as part of a compliant powertrain, it helps operators reduce maintenance costs while ensuring safe, continuous operation in harsh industrial settings.

Product Information

ABB Type Designation

M3JM 315MLA 2

Invoice Description

M3JM 315MLA 2

Product Name

3-Phase squirrel cage motor

Product Type

3JM2__M3JM_IE2_Group_I_Flameproof_Exd_mining_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE2 | Full Load (100%) 95.7 % | Partial Load (75%) 95.6 % | Partial Load (50%) 94.8 %

IE Class Data (60 Hz)

IE Class IE1 | Full Load (100%) 95.1 % | Partial Load (75%) 94.7 % | Partial Load (50%) 93.5 %

IP Class

IP66

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

S

EX-Protection

Exdb

Frame Material

Cast Iron

Frame Size

315

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB3 IM1001

Terminator Box Location

Top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

1212 kg

Gross Weight

1232 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Exdb flameproof protection and IP66 enclosure reduce explosion risk and dust ingress, delivering safer operation in mining and hazardous-area installations with lower maintenance costs. This translates to fewer unplanned shutdowns and a longer service life, supporting uptime targets and budget stability for critical process lines. The 315 cast-iron frame provides exceptional mechanical robustness, vibration resistance, and durability under heavy loads, enabling reliable operation in conveyors and ore handling systems. A top terminal box simplifies wiring in tight spaces and speeds panel installation, reducing field labor and commissioning time. IE2 efficiency, altitude tolerance up to 1000 meters, and ambient temperature of 40 °C support energy savings and dependable performance across varying plant conditions. The IMB3 IM1001 mounting class and 2-pole design ensure repeatable alignment and straightforward maintenance, whether you’re upgrading legacy equipment or integrating into modern ABB drive ecosystems. Overall, this motor delivers predictable life-cycle costs and robust compliance for mining and heavy-industry applications.

Get a Quick Quote for a ABB 3GJM311410-ASG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GJM311410-ASG?

Enquire Now

FAQs

The 3GJM311410-ASG is designed for straightforward compatibility with common variable frequency drives and motor control panels. It uses a standard 315 frame and a top-mounted terminator box to simplify wiring, reducing installation time. IE2 efficiency supports both fixed-speed and variable-speed applications in mining and hazardous-area conveyors, providing a smooth, reliable integration with ABB or third-party drive systems.

This motor features Exdb flameproof protection and an IP66 enclosure, ensuring safe operation in explosion-prone zones and environments with dust and water exposure. The rugged cast-iron frame and ICFL insulation support long service life under demanding mining conditions, while the 2-pole design and continuous S1 duty enable reliable, steady performance in continuous operations.

Yes. The motor is rated for operation up to 1000 meters above sea level and ambient temperatures up to 40 °C, making it suitable for hot or high-altitude mining settings. The combination of Exdb protection and IP66 enclosure provides robust environmental resilience, while IE2 efficiency supports steady performance across these conditions.

Maintenance is streamlined by a top-terminator box, bearing 6316/C3, and a robust 315-frame design that simplifies alignment and replacement. Standard spare parts and a global ABB service network help minimize downtime, with a clear IM class (IMB3 IM1001) and single-speed S1 duty that simplify preventive maintenance planning.

IE2 efficiency reduces energy consumption and cooling requirements, yielding measurable energy savings over time. The continuous S1 duty supports predictable operation and lower maintenance costs in mining environments. When paired with suitable drives and control systems, the motor offers a compelling ROI through reduced energy use, fewer unscheduled repairs, and longer intervals between maintenance.