ABB 3GKP311820-BDM Flameproof IE4 Motor - Exdbeb

Part Number: 3GKP311820-BDM

Quick Summary

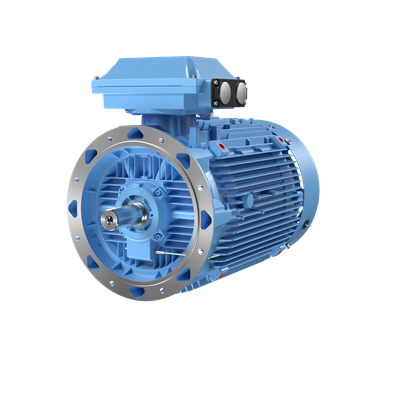

ABB 3GKP311820-BDM is a flameproof IE4 3-phase motor designed for demanding industrial applications. Engineers often face high maintenance costs and downtime when operating in hazardous areas, which this motor mitigates with rugged protection and long-life components. It carries IE4 efficiency, Ex db eb flameproof protection, IP55 enclosure, and IC411 insulation, delivering reliable performance in tough environments. With 400 V, 50 Hz supply, IMB5/IM3001 mounting, and a 315 frame, it integrates smoothly into standard plant layouts while meeting safety and regulatory requirements. This combination of durability and efficiency supports safer automation upgrades and lower total cost of ownership across industrial facilities.

Product Information

Extended Description

3GKP311820-BDM ABB: Flameproof IE4 Super Premium Efficiency LV Motors, 250 kW, 400 V (3GKP311820-BDM)

ABB Type Designation

M3KP 315LKB 2

Invoice Description

M3KP 315LKB 2

Product Name

3-Phase squirrel cage motor

Product Type

3KP4__M3KP_IE4_Flameproof_Ex_db_eb_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Medium Description

250kW, 2P, Frame Size 315, 3 Phases, 400V, 50Hz, IP55 Enclosure, IMB5/IM3001 Mounting (3GKP311820-BDM)

Short Description

250kW, 2P, Frame Size 315, 3PH, 400V, 50Hz, IP55, IMB5/IM3001

Electrical Data

Connection Configuration

D

Temperature Class Default

T4

Input Voltage (Uin)

400 V

Frequency (f)

50 Hz

Output Power

250 kW

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE4 | Full Load (100%) 96.5 % | Partial Load (75%) 96.7 % | Partial Load (50%) 96.6 %

IE Class Data (60 Hz)

IE Class IE4 | Full Load (100%) 96.2 % | Partial Load (75%) 96.2 % | Partial Load (50%) 95.8 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

EX-Protection

Exdbeb

Gas Group

IIB

Frame Material

Cast Iron

Frame Size

315

Bearing

6316/C3

Bearing NDE

6316/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Depth / Length

1446 mm

Product Net Height

858 mm

Product Net Width

590 mm

Product Net Weight

1556 kg

Gross Weight

1576 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Ex protection is designed to prevent ignition in hazardous environments, reducing combustion risk and enabling installation in chemical processing, oil & gas, and mining facilities while meeting stringent safety standards. Business impact: improved plant safety metrics, lower risk of costly shutdowns, and easier regulatory compliance as part of a broader safety automation strategy. Application: suitable for hazardous-area drives and collaboration with ABB control systems to streamline safety interlocks and maintenance routines. IE4 efficiency reduces operating energy costs by delivering higher output with lower input, translating to measurable annual savings and a faster return on investment, especially in continuous process lines and pumping stations. Application: long-running motors powering fans, pumps, and conveyors in energy-intensive plants. IP55 protection and robust housing support reliable operation in dusty or humid environments, minimizing unplanned downtime and extending service intervals. Application: cement mills, mining conveyors, and marine/offshore platforms where ingress protection matters. Frame size 315, 2-pole design with Ex protection ensures straightforward retrofit into existing installations, while IMB5/IM3001 mounting provides compatibility with common ABB mounting schemes. Application: machine upgrades and retrofits in existing lines without major structural changes. IC411 insulation class and a 40 °C ambient rating support steady performance in regional climates with elevated temperatures; altitude up to 1000 m keeps performance within spec for many North European and Arctic facilities. Frame 315, 400 V, 50 Hz, 250 kW, 2P, S1 duty delivers predictable torque and reliability in continuous operation. Application: process pumps and fans in chemical processing or metalworking. Originating in Finland, this motor aligns with tight supply chains and ABB’s global service network, supporting long-term maintenance and spare-part availability. These features collectively reduce total cost of ownership and stabilize production lines across industrial facilities.

Get a Quick Quote for a ABB 3GKP311820-BDM

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GKP311820-BDM?

Enquire Now

FAQs

For hazardous-area installations, use the Exdbeb flameproof enclosure to prevent ignition in explosive atmospheres. Ensure proper IMB5/IM3001 mounting compatibility, and verify the D-End top terminator box position as specified. The unit is rated IP55 and IC411 insulation, suitable for ambient up to 40 °C and altitudes up to 1000 m. Plan for 400 V, 50 Hz supply and a 315 frame during retrofit or new installs.

The motor operates at 400 V and 50 Hz with an output of 250 kW and two poles. It is a 3-phase squirrel cage motor designed for S1 continuous duty, with Exdbeb flameproof protection and an IP55 enclosure. Insulation class is IC411, and mounting options include IMB5/IM3001, suitable for 315 frame size.

Yes. The motor is specified for 400 V at 50 Hz, 250 kW, and uses IMB5/IM3001 mounting compatible with standard ABB installation practices. The 315 frame size and robust flameproof Ex protection enable safe operation in hazardous environments, while the IP55 rating supports ingress protection in challenging industrial settings.

This motor features IE4 efficiency, flameproof Exdbeb protection, IP55 enclosure, and IC411 insulation. It is designed for hazardous area use with a duty of S1 and 2-pole configuration, operating at 400 V and 50 Hz. The assembly supports altitude up to 1000 m and ambient temperatures up to 40 °C, with a 315 frame size.

IE4 efficiency combined with durable flameproof design reduces energy costs and scaling of maintenance in hazardous environments. The robust Ex protection and long-life bearings (e.g., 6316/C3) lower downtime and spare-part requirements. In retrofit programs, compatibility with IMB5/IM3001 mounting and a 315 frame simplifies installation, speeding up deployment and delivering a favorable total cost of ownership over the motor’s service life.