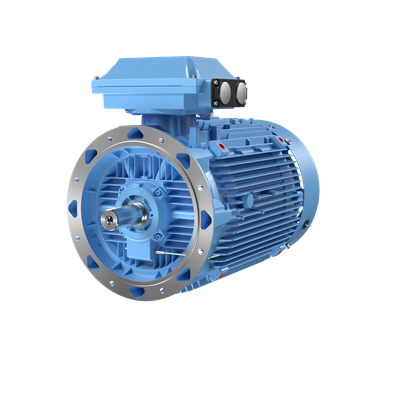

ABB 3GKP313240-BDM Flameproof Motor - IE4 Ex db eb

Part Number: 3GKP313240-BDM

Quick Summary

ABB 3GKP313240-BDM flameproof motor provides reliable 90 kW power for hazardous-area pumping and processing applications across chemical, oil, and mining facilities. Maintenance teams struggle with safety, downtime, and energy cost containment when operating in explosive atmospheres. It integrates IE4 Super Premium Efficiency, Ex db eb flameproof protection, and IP55 enclosure, enabling fast compliance and predictable performance. Designed for 400 V, 50 Hz systems with D-connection, frame size 315, and IMB5/IM3001 mounting, it fits standard plant layouts. Finland-origin build supports long-term supplier support and consistent quality, while ABB spare parts and service networks minimize lifecycle downtime. With 6 poles and robust bearings, it delivers dependable torque across a wide load range.

Product Information

Extended Description

3GKP313240-BDM ABB: Flameproof IE4 Super Premium Efficiency LV Motors, 90 kW, 400 V (3GKP313240-BDM)

ABB Type Designation

M3KP 315SMD 6

Invoice Description

M3KP 315SMD 6

Product Name

3-Phase squirrel cage motor

Product Type

3KP4__M3KP_IE4_Flameproof_Ex_db_eb_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Medium Description

90kW, 6P, Frame Size 315, 3 Phases, 400V, 50Hz, IP55 Enclosure, IMB5/IM3001 Mounting (3GKP313240-BDM)

Short Description

90kW, 6P, Frame Size 315, 3PH, 400V, 50Hz, IP55, IMB5/IM3001

Electrical Data

Connection Configuration

D

Temperature Class Default

T4

Input Voltage (Uin)

400 V

Frequency (f)

50 Hz

Output Power

90 kW

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE4 | Full Load (100%) 95.6 % | Partial Load (75%) 95.6 % | Partial Load (50%) 95.1 %

IE Class Data (60 Hz)

IE Class IE4 | Full Load (100%) 95.8 % | Partial Load (75%) 95.7 % | Partial Load (50%) 95.0 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

6

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

EX-Protection

Exdbeb

Gas Group

IIB

Frame Material

Cast Iron

Frame Size

315

Bearing

6319/C3

Bearing NDE

6316/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Depth / Length

1204 mm

Product Net Height

858 mm

Product Net Width

590 mm

Product Net Weight

1056 kg

Gross Weight

1076 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Ex protected design and flameproof enclosure enable safe operation in hazardous locations, reducing risk and enabling regulatory compliance in chemical, oil, and mining facilities. The Exdbeb protection profile translates to lower risk of ignition in IIB gas environments, which in turn supports safer maintenance routines and easier site approvals. The result is less unplanned downtime and a more predictable total cost of ownership for critical process equipment. IE4 Super Premium Efficiency delivers tangible energy savings during continuous operation, lowering electricity bills and cooling loads while improving sustainability metrics. This is particularly valuable in pump and conveyor lines where running hours are high and marginal gains compound over time. IP55 enclosure, IC411 insulation class, and a T4 temperature class provide rugged performance in dusty or hot plants, translating to longer service intervals and reduced spare-part consumption. The 400 V, 50 Hz rating aligns with standard electrical distributions, simplifying installation and drive integration. Frame size 315, cast-iron construction, and IMB5/IM3001 mounting support robust mechanical integrity, easing retrofits and minimizing retrofit risk when upgrading legacy equipment. The D connection configuration simplifies wiring layouts, enabling quicker commissioning and safer startup in installed basements or outdoor sites. Bearing arrangements 6319/C3 and 6316/C3 with a 6-pole design deliver consistent torque across load profiles, improving process stability and system responsiveness. Altitude up to 1000 m and ambient temperature up to 40 °C are accommodated through engineered tolerances, reducing the need for premium derating in typical industrial sites. In short, this motor supports compliant, reliable, and energy-efficient hazardous-area driven systems with strong lifecycle value.

Get a Quick Quote for a ABB 3GKP313240-BDM

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GKP313240-BDM?

Enquire Now

FAQs

The motor uses a D connection configuration and is rated for 400 V, 50 Hz, 6-pole operation, with frame size 315 and IMB5/IM3001 mounting. It is designed to integrate with ABB industrial drives and control systems, enabling straightforward commissioning and predictable drive performance in standard electrical distributions.

It features Exdbeb flameproof protection for IIB gas environments, IP55 enclosure protection, and IC411 insulation class. The IE4 efficiency rating supports energy compliance, while the overall design targets safe operation in explosive atmospheres, aligning with typical industry standards for chemical, oil, and refinery settings.

Yes. The IP55 enclosure, IC411 insulation class, and rugged cast-iron frame in combination with a 40 °C ambient rating and up to 1000 m altitude make it well-suited for outdoor installations and dusty facilities, reducing derating needs and maintenance risks in challenging environments.

The motor uses IMB5 IM3001 mounting and a D-End top terminator box location, with a frame size of 315 and 6-pole configuration. Dimensions and weight at 1056 kg net (1076 kg gross) fit in standard plant basements or outdoor platforms, while the cast-iron frame provides robust mechanical rigidity during retrofits.

IE4 efficiency reduces energy consumption and cooling demands, lowering operating costs. The flameproof Ex protection minimizes risk-related downtime, and the durable cast-iron construction plus ABB service support deliver longer service intervals and easier access to spare parts, contributing to lower lifecycle downtime and predictable maintenance planning.