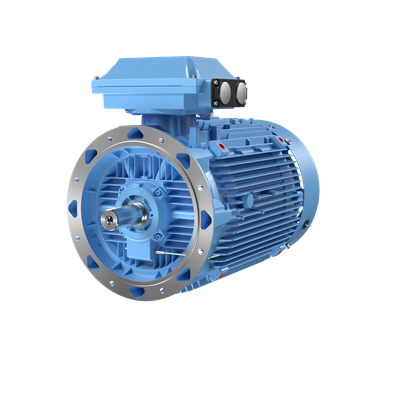

ABB 3GKP351810-BDM 3-Phase Squirrel Cage Motor - Flameproof IE4 Exdbeb

Part Number: 3GKP351810-BDM

Quick Summary

ABB 3GKP351810-BDM is a flameproof, IE4-rated 3-phase squirrel cage motor designed for hazardous-area applications. This motor delivers reliable performance in demanding environments while reducing energy consumption and maintenance requirements. Operators often struggle with safety compliance, energy costs, and retrofit compatibility in confined spaces; this solution addresses those challenges with robust explosion protection, superior efficiency, and a compact IMB5/IM3001 mounting footprint. Key protections include IP55 enclosure and Exdbeb flameproof certification, ensuring safe operation in corrosive or explosive atmospheres. By combining premium efficiency with proven ABB engineering, it supports lower life-cycle costs and easier regulatory reporting, making it a compelling choice for industrial plants seeking reliable, energy-efficient motors in hazardous locations.

Product Information

Extended Description

3GKP351810-BDM ABB: Flameproof IE4 Super Premium Efficiency LV Motors, 500 kW, 400 V (3GKP351810-BDM)

ABB Type Designation

M3KP 355LKA 2

Invoice Description

M3KP 355LKB 2

Product Name

3-Phase squirrel cage motor

Product Type

3KP4__M3KP_IE4_Flameproof_Ex_db_eb_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015394

Medium Description

500kW, 2P, Frame Size 355, 3 Phases, 400V, 50Hz, IP55 Enclosure, IMB5/IM3001 Mounting (3GKP351810-BDM)

Short Description

500kW, 2P, Frame Size 355, 3PH, 400V, 50Hz, IP55, IMB5/IM3001

Electrical Data

Connection Configuration

D

Temperature Class Default

T4

Input Voltage (Uin)

400 V

Frequency (f)

50 Hz

Output Power

500 kW

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE4 | Full Load (100%) 96.5 % | Partial Load (75%) 96.5 % | Partial Load (50%) 96.0 %

IE Class Data (60 Hz)

IE Class IE4 | Full Load (100%) 96.2 % | Partial Load (75%) 95.9 % | Partial Load (50%) 95.1 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

2

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

EX-Protection

Exdbeb

Gas Group

IIB

Frame Material

Cast Iron

Frame Size

355

Bearing

6316M/C3

Bearing NDE

6316M/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Depth / Length

1764 mm

Product Net Height

984 mm

Product Net Width

700 mm

Product Net Weight

2334 kg

Gross Weight

0 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: Exdbeb flameproof protection provides explosion-protected operation in IIB gas environments. Business Impact: Enhances safety, reduces risk of ignition, and supports compliance with hazardous-area regulations. Application: Chemical plants, oil & gas facilities, mining operations that require reliable flameproof motors. Feature: IE4 efficiency delivers energy savings across continuous operation. Business Impact: Lower operating costs and improved sustainability metrics over motor life. Application: Pumping, fans, compressors in 400 V, 50 Hz systems. Feature: 500 kW output at 400 V with a 2-pole design. Business Impact: High power density for compact drives and reduced footprint; easier retrofits into existing plants. Application: Heavy-duty conveyors and rotary equipment in large-scale plants. Feature: Frame 355, cast iron construction, IP55 enclosure, and IMB5/IM3001 mounting. Business Impact: Superior mechanical ruggedness and long bearing life in tough environments; straightforward installation and dependable maintenance windows. Application: Industrial plants with demanding temperatures up to 40 °C and elevation up to 1000 m. Feature: Ex-protection, gas group IIB, insulation class ICLF. Business Impact: Meets stringent safety standards and supports durable insulation under heat and vibration. Application: Systems exposed to heat, dust, and corrosive atmospheres. Industry knowledge: The combination of Exdbeb protection, IP55, and IE4 efficiency is a common criterion for modern hazardous-area motor selections, enabling safer operation, reduced downtime, and a clear pathway toward regulatory compliance.

Get a Quick Quote for a ABB 3GKP351810-BDM

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GKP351810-BDM?

Enquire Now

FAQs

This motor uses a D connection configuration, with a 355 frame and a cast-iron housing. It supports IMB5 IM3001 mounting and a D-End top terminator box location, plus an IP55 enclosure and Exdbeb flameproof protection. Ensure proper cable entry, alignment, and clearance for safe operation at ambient up to 40 °C and altitude up to 1000 m, and verify compatibility with your drive system.

At 50 Hz this motor delivers 500 kW of output power with a 2-pole configuration and a 400 V supply. It is rated IE4 for premium efficiency and IP55 for enclosure protection. The device is designed for hazardous areas with Exdbeb protection and gas group IIB, making it suitable for demanding industrial processes.

Yes. The ABB 3GKP351810-BDM features Exdbeb flameproof protection and an IP55 enclosure, designed for hazardous locations, including IIB gas groups. It supports safe operation in environments where ignition risk must be mitigated, while delivering robust mechanical performance and high reliability.

Key certifications include Exdbeb flameproof protection, IP55 enclosure, and insulation class ICLF. It is designed for hazardous-area operation in IIB gas environments, with a 355 frame and IMB5/IM3001 mounting. Additional data include Finland origin, customs tariff 85015394, and the motor’s 400 V, 50 Hz specification.

Minimum order quantity is 1 piece, and it is not made to order, allowing for straightforward procurement. The motor’s robust cast-iron frame, 2-pole design, and IMB5 mounting support long service life, while IE4 efficiency reduces energy costs over time. Availability is supported by its hazardous-area certification and reliable ABB engineering, making retrofits and maintenance planning simpler.