ABB 3GKP353420-BDM 3-Phase Flameproof Motor - IE4 Exdbeb

Part Number: 3GKP353420-BDM

Quick Summary

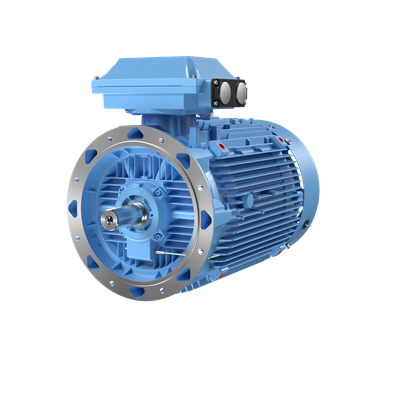

ABB 3GKP353420-BDM is a flameproof IE4 250 kW three-phase motor designed for hazardous-area duty across chemical, oil & gas, and mining environments. Sourcing this type of equipment often introduces downtime and compliance risk when non-specialist suppliers deliver niche explosion-protected devices. The motor combines ATEX/IECEx flameproof protection (Exdbeb) with IP55 enclosure and IE4 efficiency to minimize energy waste and maintenance in harsh settings. With a 6-pole, 400 V, 50 Hz configuration and a robust frame, it supports reliable operation in high-temperature conditions up to 40 °C and at elevations up to 1000 m, helping you reduce total cost of ownership while preserving uptime and safety.

Product Information

Extended Description

3GKP353420-BDM ABB: Flameproof IE4 Super Premium Efficiency LV Motors, 250 kW, 400 V (3GKP353420-BDM)

ABB Type Designation

M3KP 355MLB 6

Invoice Description

M3KP 355MLB 6

Product Name

3-Phase squirrel cage motor

Product Type

3KP4__M3KP_IE4_Flameproof_Ex_db_eb_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Medium Description

250kW, 6P, Frame Size 355, 3 Phases, 400V, 50Hz, IP55 Enclosure, IMB5/IM3001 Mounting (3GKP353420-BDM)

Short Description

250kW, 6P, Frame Size 355, 3PH, 400V, 50Hz, IP55, IMB5/IM3001

Electrical Data

Connection Configuration

D

Temperature Class Default

T4

Input Voltage (Uin)

400 V

Frequency (f)

50 Hz

Output Power

250 kW

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE4 | Full Load (100%) 96.5 % | Partial Load (75%) 96.6 % | Partial Load (50%) 96.2 %

IE Class Data (60 Hz)

IE Class IE4 | Full Load (100%) 96.5 % | Partial Load (75%) 96.4 % | Partial Load (50%) 95.8 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

6

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

EX-Protection

Exdbeb

Gas Group

IIB

Frame Material

Cast Iron

Frame Size

355

Bearing

6322/C3

Bearing NDE

6316/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Depth / Length

1584 mm

Product Net Height

968 mm

Product Net Width

700 mm

Product Net Weight

2194 kg

Gross Weight

0 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature → Business Impact → Application: Flameproof Exdbeb protection reduces ignition risk in hazardous zones, lowering safety-related downtime and enabling compliant installations in ATEX/IECEx environments; Application-ready in chemical plants and oil & gas facilities, minimizing risk and facilitating regulatory adherence. Feature → Business Impact → Application: IE4 Super Premium efficiency delivers measurable energy savings across load profiles, translating to lower operating costs and improved sustainability metrics for continuous-process operations; Application: large-motor drives in pumping and ventilation duties where energy use is critical. Feature → Business Impact → Application: IP55 enclosure and 40 °C ambient tolerance improve reliability in dusty, hot industrial floors, reducing spontaneous outages and service interventions; Application: refineries, mines, and processing plants with demanding ambient conditions. Feature → Business Impact → Application: Cast Iron frame (355) with robust bearings (6322/C3, 6316/C3) and IMB5/IM3001 mounting delivers vibration resistance and long service life, lowering maintenance frequency and spare-part costs; Application: demanding continuous-duty installations in hazardous zones. Feature → Business Impact → Application: Exdbeb flameproof protection and IIB gas group support ensure regulatory compliance and peace of mind during startup in combustible atmospheres; Application: offshore platforms and process plants where safety certification and protection are critical. Feature → Business Impact → Application: 6-pole, 3-phase, 400 V, 50 Hz configuration aligns with standard industrial power distribution, enabling straightforward installation and compatibility with existing ABB controls and drives; Application: retrofits and new builds across Industries seeking reliable, standards-compliant power transmission.

Get a Quick Quote for a ABB 3GKP353420-BDM

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GKP353420-BDM?

Enquire Now

FAQs

This Exdbeb flameproof motor is designed for ATEX/IECEx environments, with IP55 protection and a frame suitable for IMB5/IM3001 mounting. Ensure correct surface preparation, proper conduit sealing, and adherence to local ATEX/IECEx installation standards. Verify ambient limits (up to 40 °C) and altitude (up to 1000 m) are not exceeded to maintain performance and safety margins.

The unit provides 250 kW output at 400 V with 6 poles, 50 Hz operation, in a 355 frame. It supports a continuous S1 duty, IC411 insulation, and IE4 efficiency. It’s designed for single-speed operation with Ex protection, IP55 enclosure, and a rugged cast-iron frame for demanding industrial environments.

Yes. With Exdbeb flameproof protection, IP55 enclosure, and an IE4 efficiency class, it is well-suited for hazardous-area processes in oil & gas and chemical plants. The motor meets ATEX/IECEx expectations for explosion-protected equipment and supports reliable operation under elevated ambient temperatures.

The motor features Exdbeb flameproof protection and IP55, aligning with ATEX/IECEx guidelines for hazardous zones. Its insulation and duty class support continuous operation in demanding environments. Ensure local regulatory conformity, facility-specific approvals, and proper mounting per IMB5/IM3001 standards during commissioning.

IE4 efficiency drives notable energy savings across load profiles, with full-load efficiency around 96.5% at 50 Hz and similar values at 60 Hz. Reduced energy consumption lowers operating costs, while robust construction and explosion-protected features minimize downtime and maintenance costs in hazardous areas, delivering a favorable total cost of ownership over the motor’s service life.