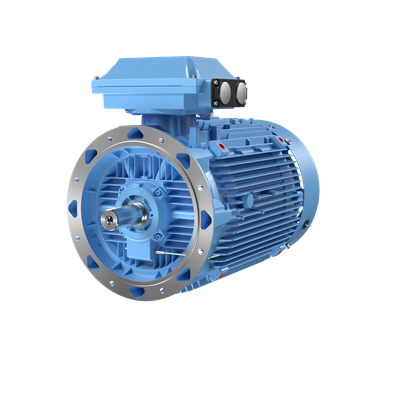

ABB 3GKP353820-BDM Flameproof IE4 Motor - Ex db eb

Part Number: 3GKP353820-BDM

Quick Summary

The 3GKP353820-BDM flameproof motor delivers reliable, high-efficiency power for demanding mineral processing and chemical plant applications. Industries face costly downtime and maintenance when motors fail in harsh environments. This motor features Ex db eb explosion protection, IP55 enclosure, and IE4 efficiency, and a robust 355 kW rating at 400 V, helping you meet ATEX/IEC standards and lower energy use. Designed for flameproof installations with IMB5/IM3001 mounting compatibility and 6-pole operation, it integrates with existing ABB control systems for predictable performance and reduced lifecycle costs.

Product Information

Extended Description

3GKP353820-BDM ABB: Flameproof IE4 Super Premium Efficiency LV Motors, 355 kW, 400 V (3GKP353820-BDM)

ABB Type Designation

M3KP 355LKB 6

Invoice Description

M3KP 355LKB 6

Product Name

3-Phase squirrel cage motor

Product Type

3KP4__M3KP_IE4_Flameproof_Ex_db_eb_motor

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Medium Description

355kW, 6P, Frame Size 355, 3 Phases, 400V, 50Hz, IP55 Enclosure, IMB5/IM3001 Mounting (3GKP353820-BDM)

Short Description

355kW, 6P, Frame Size 355, 3PH, 400V, 50Hz, IP55, IMB5/IM3001

Electrical Data

Connection Configuration

D

Temperature Class Default

T4

Input Voltage (Uin)

400 V

Frequency (f)

50 Hz

Output Power

355 kW

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC411

IE Class Data (50 Hz)

IE Class IE4 | Full Load (100%) 96.6 % | Partial Load (75%) 96.5 % | Partial Load (50%) 95.9 %

IE Class Data (60 Hz)

IE Class IE4 | Full Load (100%) 96.5 % | Partial Load (75%) 96.2 % | Partial Load (50%) 95.4 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

6

Two Speed Motor

No

Type of Duty

S1

Voltage Code

D

EX-Protection

Exdbeb

Gas Group

IIB

Frame Material

Cast Iron

Frame Size

355

Bearing

6322/C3

Bearing NDE

6316/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Depth / Length

1834 mm

Product Net Height

968 mm

Product Net Width

700 mm

Product Net Weight

2614 kg

Gross Weight

0 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Ex protection is built into the motor design, enabling safe operation in hazardous zones such as chemical plants and refineries. The protective enclosure, flame-arresting construction, and robust sealing minimize ignition risks in environments with flammable gases or dust, supporting compliance with ATEX and IECEx requirements while delivering dependable starts and smooth torque delivery in pumps, mixers, and conveyors. IE4 Super Premium efficiency is achieved through optimized winding and advanced copper-loss reductions, delivering meaningful energy savings during continuous operation. Lower energy consumption translates to reduced operating expenses, improved utility metrics, and better sustainability profiles for projects with strict targets. IP55 enclosure plus an insulation class design provides durable protection against dust and moisture while maintaining thermal performance at 40 C ambient. The 355 kW rating and 6 poles deliver reliable full-load performance, supporting stable process control in environments with vibration and heat, with altitude tolerance up to 1000 meters. IMB5 IM3001 mounting compatibility and a D-type connection simplify installation and integration with ABB drives, reducing commissioning time and eliminating the need for bespoke scaffolding. This compatibility also ensures easier spare-parts management and consistent interfaces for maintenance teams. Designed for S1 continuous duty in demanding industrial applications, the motor maintains reliable torque and thermal stability under long-running operation. The robust frame size 355 and 3-phase 400 V supply are well-suited for heavy-duty pumps, fans, and conveyors, while Ex db eb protection helps meet stringent regulatory requirements and enhances overall plant safety.

Get a Quick Quote for a ABB 3GKP353820-BDM

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GKP353820-BDM?

Enquire Now

FAQs

To install, refer to the IMB5/IM3001 mounting guidelines and ensure proper alignment with the machinery frame. Use the D connection configuration and secure the terminal box in its D-end location. Verify Ex db eb protection ratings are intact, connect to a suitable 400 V, 50 Hz supply, and confirm IP55 sealing for protection against dust and water ingress. Proper torque on mounting bolts and electrical connections minimizes vibration and extends bearing life.

The motor delivers 355 kW output at 400 V with a 6-pole configuration for 50 Hz operation. It is a 3-phase squirrel cage design with Ex protection and IE4 efficiency. The connection is configured as D, with a duty class of S1 for continuous operation, and an IP55 enclosure suitable for demanding industrial environments.

Yes. The 3GKP353820-BDM includes Ex db eb flameproof protection and IP55 enclosure, making it well-suited for hazardous-zone applications such as chemical processing, oil refining, and mining. The IE4 efficiency enhances energy performance, and mounting compatibility with IMB5/IM3001 simplifies integration with existing ABB automation and control systems.

Key certifications include Ex protection for hazardous areas, IP55 enclosure, and IE4 efficiency rating. The insulation class is ICLF, with IC411 electrical class, and a design approved for ATEX/IECEx environments. The motor also supports 6-pole operation and flameproof Exdbeb protection, ensuring compliance and safety across global deployments.

Expect reduced downtime due to robust flameproof design and high IE4 efficiency lowering energy costs. The IMB5 IM3001 mounting compatibility simplifies installation and spare-parts planning, shortening commissioning and maintenance intervals. Over the motor’s life, improved reliability and lower energy consumption translate to a lower total cost of ownership in heavy-duty applications like pumps, fans, and conveyors.