ABB 3GLL252237-BDC 3Phase SynRM Motor - IE5 Water Cooled

Part Number: 3GLL252237-BDC

Quick Summary

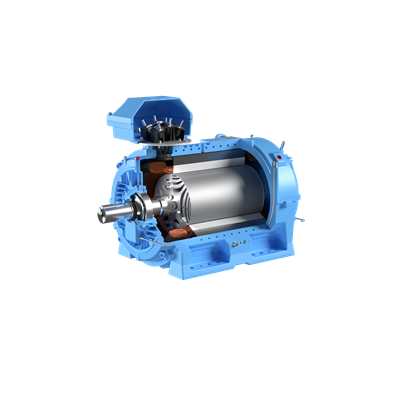

ABB 3GLL252237-BDC 3Phase Synchronous reluctance motor is a high-efficiency, water-cooled drive solution for heavy industrial applications. It targets reduced energy consumption and improved thermal performance in demanding environments where uptime and efficiency matter. Operators often contend with heat load, energy costs, and cooling system strain; this motor addresses those challenges with premium IE5 efficiency and robust IP55 protection. The design incorporates IE5 energy class data, IP55 enclosure, and IC71W insulation, ensuring reliable operation in typical factory settings while maintaining compact integration with IMB5/IM3001 mounting. For plants seeking lower total cost of ownership, this motor offers meaningful gains in efficiency, cooling efficiency, and long-term maintenance predictability, especially in steel, packaging, and process industries.

Product Information

Extended Description

3GLL252237-BDC ABB: IE5 Water Cooled SynRM Motors, 132 kW, 400 V (3GLL252237-BDC)

ABB Type Designation

M3LL 250SMC 4

Invoice Description

M3LL 250SMC 4

Product Name

3Phase Synchronous reluctance motor

Product Type

3LL5__M3LL_IE5__Water_cooled_SynRM

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015381

Medium Description

132kW, 4 Poles, Frame Size 200, 3 Phases, 400V, 50Hz, IP55 Enclosure, IMB5/IM3001 Mounting (3GLL252237-BDC)

Short Description

132kW, 4 P, Frame Size 200, 3PH, 400V, 50Hz, IP55, IMB5/IM3001

Electrical Data

Connection Configuration

D

Temperature Class Default

--

Input Voltage (Uin)

400 V

Frequency (f)

50 Hz

Motor Operational Voltage

370 V

Output Power

132 kW

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC71W

IE Class Data (50 Hz)

IE Class IE5 | Full Load (100%) 96.2 % | Partial Load (75%) 95.9 % | Partial Load (50%) 95.3 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S9

Voltage Code

D

Frame Material

Aluminum

Frame Size

250

Bearing

6315/C3

Bearing NDE

6213/HC5C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End top

Package Level 1 Units

0 pallet (lift)

Product Net Weight

459 kg

Gross Weight

469 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature → Business Impact → Application: The IE5 efficiency of the water-cooled SynRM reduces full-load energy consumption, delivering measurable operating cost reductions for continuous-process drives and high-duty conveyors. In practice, facilities see lower utility bills and cooler equipment rooms, enabling more compact cooling systems and easier HVAC planning for manufacturing lines. The 132 kW output at 400 V with a 4-pole design provides strong torque and smooth ramping for mixers, extruders, and material-handling systems, reducing start-up torque spikes and improving process stability. Application-wise, this suits heavy-duty pumps, fans, and conveyors in Automotive, Metals, and Packaging lines where consistent power delivery is critical. Compatibility with IMB5/IM3001 mounting and a frame size of 250 simplifies retrofits and new installations in existing ABB ecosystems, minimizing downtime during commissioning. The IP55 enclosure and IC71W insulation support dependable operation in medium-contaminant environments and at ambient temperatures up to 40 °C, with altitude up to 1000 m, protecting bearings and windings from ingress and heat buildup. The D connection configuration and 3-phase, 400 V, 50 Hz input align with standard industrial power rails, shortening wiring and commissioning time and reducing field installation risk. By combining water cooling with high-efficiency design, the motor maintains optimal temperature rise, enabling longer bearing life and reduced cooling fan load in continuous-run applications. This translates to lower maintenance cycles and predictable maintenance windows, which is especially valuable in continuous processes like extrusion, pumping, and machining centers. The aluminum frame and precision bearings (6315/C3, 6213/HC5C3) provide robust mechanical integrity, supporting life-cycle cost reduction in demanding production lines and reducing the risk of unplanned downtime. Overall, this SynRM motor offers a reliable upgrade path for facilities pursuing energy efficiency, heat management, and long-term performance in modern automation architectures.

Get a Quick Quote for a ABB 3GLL252237-BDC

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GLL252237-BDC?

Enquire Now

FAQs

Yes. The 3GLL252237-BDC is designed for IMB5/IM3001 mounting with Frame Size 250. Its D-End top terminator box location simplifies wiring during installation and supports straightforward retrofits in existing ABB-driven lines.

The motor operates at 400 V, 50 Hz with a 132 kW output and 4 poles. It achieves IE5 efficiency with Full Load 96.2% and supports stable performance under Partial Load conditions, making it suitable for steady-state industrial drives.

Ideal for heavy-duty conveyors, pumps, and fans in metals, packaging, and process industries. The water-cooled SynRM design helps manage heat in high-duty cycles while maintaining high efficiency, making it well-suited for continuous operations in challenging environments.

It features IP55 protection and IC71W insulation with a Finland (FI) origin. The motor is rated for ambient up to 40 °C and altitude up to 1000 m, combining robust protection with high-performance insulation for industrial settings.

The IE5 efficiency and water cooling reduce cooling loads and energy costs, while the robust IMB5 mounting and aluminum frame support longer bearing life and quicker installation. These factors contribute to lower maintenance frequency and a favorable return on investment in continuous-process environments.