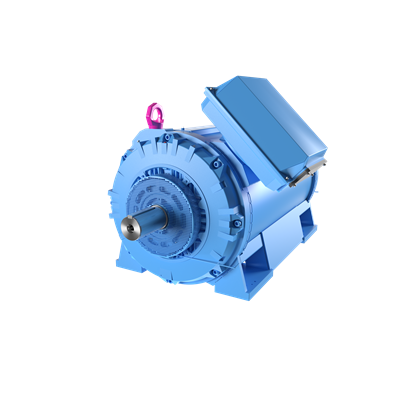

ABB 3GLP502510-BYK 3-Phase water-cooled motor IE3 IP55

Part Number: 3GLP502510-BYK

Quick Summary

ABB 3GLP502510-BYK 3-Phase water-cooled motor powers high-efficiency, continuous-duty drives in heavy industry applications. Engineers often contend with overheating, maintenance downtime, and energy waste in large motors. This design delivers IE3 efficiency, IP55 protection, and IC71W insulation to withstand harsh environments. Manufactured in Finland, it combines a welded steel frame, robust bearings, and a compact D-End right side terminator box to simplify installation and reduce field wiring. The result is predictable performance, longer service life, and lower total cost of ownership for automation projects in mining, processing, and heavy manufacturing. By leveraging frame size 500 and a 4-pole design, it scales across demanding loads while meeting stringent safety and efficiency targets.

Product Information

Extended Description

3GLP502510-BYK ABB: M3LP 500LA 4

ABB Type Designation

M3LP 500LA 4

Invoice Description

M3LP 500LA 4

Product Name

3-Phase squirrel cage motor

Product Type

3LP3__water_cooled_motor_IE3

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015399

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC71W

IE Class Data (60 Hz)

IE Class NA | Full Load (100%) 97.6 % | Partial Load (75%) 97.7 % | Partial Load (50%) 97.4 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S1

Voltage Code

Y

Frame Material

Welded Steel

Frame Size

500

Bearing

6330M/C3

Bearing NDE

6326M/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

5350 kg

Gross Weight

5390 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: Water-cooled design paired with IE3 efficiency. Business impact: superior thermal management allows sustained 100% duty without derating, reducing downtime and maintenance costs. Application: heavy-duty conveyors, grinders, and process lines in mining and metal fabrication. Feature: IP55 protection and IC71W insulation. Business impact: robust operation in dusty, damp environments and during washdowns, minimizing unexpected outages. Application: outdoor installations and harsh production floors in chemical and steel plants. Feature: Frame 500 welded steel with D-End right-side terminator box. Business impact: durable housing and easier field wiring shorten installation time and improve serviceability. Application: new build integrations and retrofits in space-constrained facilities. Feature: IMB5 IM3001 bearing arrangement with 6330M/C3 and 6326M/C3 bearings. Business impact: improved reliability and extended maintenance intervals for high-vibration machinery. Application: crushers, grinders, and heavy-duty conveyors in minerals processing. Feature: Altitude up to 1000 m and ambient temperature up to 40 °C. Business impact: reliable performance in high-altitude and hot environments, reducing risk of thermal overload. Application: mining, hillside facilities, and mountainous processing plants. Feature: 4-pole, 3-phase squirrel cage design with 0–1000 m altitude rating. Business impact: proven torque characteristics and straightforward procurement for standard automation modules. Application: general heavy automation needing robust, long-life motors.

Get a Quick Quote for a ABB 3GLP502510-BYK

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GLP502510-BYK?

Enquire Now