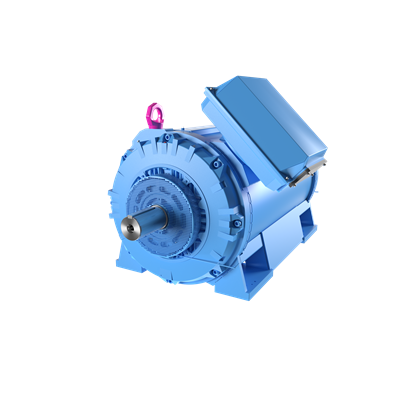

ABB 3GLP502520-BUK 3LP3__water_cooled_motor_IE3 - IP55

Part Number: 3GLP502520-BUK

Quick Summary

ABB 3GLP502520-BUK is a high-efficiency 3LP3 water-cooled motor designed for heavy-duty industrial drives across process, metalworking, and packaging lines. When heat buildup, energy use, and downtime threaten production, this motor’s advanced cooling and rugged IP55 protection help sustain continuous operation. It meets IE3 efficiency targets, IP55 ingress protection, and IC71W insulation class, aligning with global standards and maintenance routines. For plant owners and maintenance teams, the result is lower energy bills, longer maintenance intervals, and predictable performance under full load. Built in Finland with a 500-frame design, it delivers strong torque and installation flexibility for scalable automation projects.

Product Information

Extended Description

3GLP502520-BUK ABB: M3LP 500LB 4

ABB Type Designation

M3LP 500LB 4

Invoice Description

M3LP 500LB 4

Product Name

3-Phase squirrel cage motor

Product Type

3LP3__water_cooled_motor_IE3

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015399

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC71W

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 97.7 % | Partial Load (75%) 97.8 % | Partial Load (50%) 97.7 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S1

Voltage Code

U

Frame Material

Welded Steel

Frame Size

500

Bearing

6330M/C3

Bearing NDE

6326M/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

5650 kg

Gross Weight

5690 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: Water-cooled design with a welded steel frame delivers superior thermal management. Business Impact: Enables higher continuous output without overheating, reducing derating during peak loads. Application: ideal for hot environments in process lines, metalworking, and chemical processing. Feature: IP55 protection and IC71W insulation class provide robust resistance to dust, moisture, and high operating temperatures. Business Impact: extends service life and lowers maintenance frequency in demanding factories. Application: outdoor installations or damp manufacturing floors where reliability is critical. Feature: 4-pole design with IMB5 IM3001 alignment and bearings 6330M/C3, plus NDE bearing 6326M/C3. Business Impact: reduces vibration, improves bearing life, and minimizes unplanned downtime. Application: high-torque, continuous-drive applications in heavy equipment lines. Feature: Altitude tolerance up to 1000 m and ambient temperature rating of 40 °C. Business Impact: preserves cooling margins and performance at medium elevations and hot plants. Application: plants located in elevated or high-ambient sites where heat dissipation is a challenge. Feature: Terminator box located at D-End right side with a 0 pallet startup package and 1 piece MOQ. Business Impact: simplifies installation planning, wiring, and inventory management for large installations. Application: scalable automation projects requiring predictable lead times and streamlined logistics.

Get a Quick Quote for a ABB 3GLP502520-BUK

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GLP502520-BUK?

Enquire Now

FAQs

Yes, the motor is a 3-phase machine designed for continuous duty with a 4-pole configuration. Mounting and exact voltage compatibility should follow the ABB datasheet for the 500-frame, considering the Voltage Code U and the D-End right-side terminator box. For best results, use proper motor-mounted supports and compliant cabling to ensure IP55 integrity and thermal management.

The IE3 efficiency class is evidenced by the data: Full Load efficiency around 97.7%, Partial Load (75%) about 97.8%, and Partial Load (50%) around 97.7%. This indicates strong performance across operating points, contributing to energy savings in continuous-duty applications.

Yes. The product type is explicitly water-cooled, designed for sustained operation in high-heat environments. Its IP55 protection, IC71W insulation, and 4-pole configuration support heavy-duty processes and continuous automation lines where cooling and reliability are critical.

Key standards include IE3 energy efficiency, IP55 protection for dust and moisture resistance, and IC71W insulation class. It also carries a 4-pole IMB5 IM3001 mechanical class and a D-End right-side terminator box arrangement, aligning with typical industrial electrical standards.

Expect lower energy costs due to IE3 efficiency and reduced heat load from water cooling. The rugged bearings (6330M/C3 and 6326M/C3) and IP55 protection minimize maintenance needs in harsh environments, improving uptime. Plan for periodic inspections of bearings and cooling connections to maximize total cost of ownership savings.