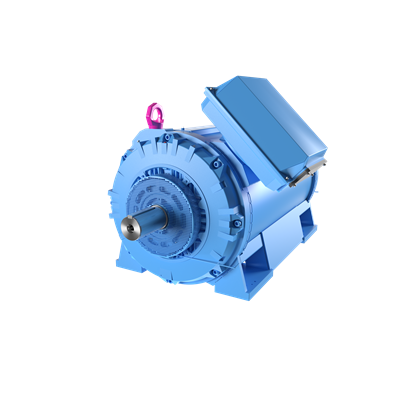

ABB 3GLP502520-LUK 3-Phase squirrel cage motor - IP55

Part Number: 3GLP502520-LUK

Quick Summary

ABB 3GLP502520-LUK is a 3-phase squirrel cage motor for heavy-duty industrial drives. Many plants face downtime when motors overheat or fail at high ambient temperatures. This unit meets IE3 efficiency, IP55 protection, and IC71W insulation, enabling reliable performance in demanding environments. Designed for water-cooled cooling, 40 °C ambient conditions, and up to 1000 m altitude, it sustains torque and flow without compromising efficiency. By standardizing on a welded-steel frame, ABB ensures predictable maintenance, compatibility with IMB3 IM1001 mounting, and scalable integration across processes. Site engineers gain reduced spare-part inventories thanks to common ABB components and robust bearing systems. Operational cost savings come from high energy efficiency and lower cooling load, supporting ROI in the mid-term.

Product Information

Extended Description

3GLP502520-LUK ABB: No Description Available

ABB Type Designation

M3LP 500LB 4

Product Name

3-Phase squirrel cage motor

Product Type

3LP3__water_cooled_motor_IE3

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015399

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC71W

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 97.7 % | Partial Load (75%) 97.8 % | Partial Load (50%) 97.7 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Voltage Code

U

Frame Material

Welded Steel

Frame Size

500

Bearing

6330M/C3

Bearing NDE

6326M/C3

IM Class

IMB3 IM1001

Terminator Box Location

D-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

5650 kg

Gross Weight

5690 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: Water-cooled motor design delivers superior thermal management, enabling sustained high-load operation. Business Impact: Maintains constant torque and prevent derating under hot environments, reducing unscheduled downtime. Application: Heavy-duty conveyors and pumps in process lines where ambient temperature approaches spec limits. Long-tail keywords: water-cooled motor, high-power drive efficiency. Feature: IE3 efficiency class provides tangible energy savings over standard IE2 motors. Business Impact: Lower energy costs and improved total cost of ownership for continuous-operation equipment. Application: Energy-intensive industrial drives like pumps and fans in manufacturing facilities. Long-tail keywords: IE3 motor, energy-efficient industrial motor. Feature: IP55 enclosure protects against dust and water ingress in challenging environments. Business Impact: Extended service life with reduced maintenance frequency, even in outdoor or dirty production areas. Application: Outdoor installations, wash-down zones, and dusty workshops. Long-tail keywords: IP55 protection, rugged motor. Feature: 4-pole design with welded steel frame (Frame 500) provides reliable speed and mounting compatibility. Business Impact: Predictable performance for standard VFDs and easy retrofits in existing lines. Application: Conveyor drives, mixer systems, and pump trains in legacy plants. Long-tail keywords: 4-pole motor, 500-frame motor, IMB3 mounting. Feature: Bearing configuration (6330M/C3 and 6326M/C3) enhances longevity under heavy loads. Business Impact: Reduced bearing wear and quieter operation, lowering maintenance costs and downtime. Application: High-load motors in continuous-duty cycles. Long-tail keywords: precision bearings, IMB3 alignment. Feature: IC insulation class ICLF and IC71W insulation enable resilience in elevated ambient temperatures and variable conditions. Business Impact: Maintains insulation integrity for longer service life and safer operation. Application: Plants near heat sources or with temperature fluctuations. Long-tail keywords: insulation class ICLF, insulation system stability. Feature: Thoroughly documented mechanical and electrical data supports fast installation and compliance checks. Business Impact: Shorter commissioning time and easier integration with existing control systems. Application: New builds and plant upgrades where standardization is key. Long-tail keywords: IEC/EN compliance readiness, standard mounting conventions. The combination of these features translates to measurable outcomes: lower energy consumption, reduced cooling requirements, better uptime, and a smoother path to lifecycle savings in industrial automation environments. The motor’s compatibility with standard ABB components and mounting conventions simplifies spares planning and maintenance scheduling, particularly for facilities targeting upgrades to IE3-compliant, high-efficiency drives.

Get a Quick Quote for a ABB 3GLP502520-LUK

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GLP502520-LUK?

Enquire Now