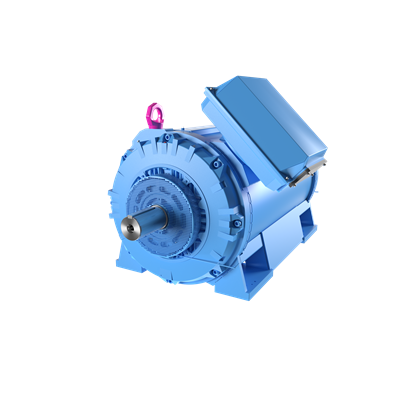

ABB M3LP 500LC 4 3-Phase Squirrel Cage Motor - IP55/IE3

Part Number: 3GLP502530-BUK

Quick Summary

ABB M3LP 500LC 4 is a 3-phase squirrel cage motor for heavy-duty industrial drives and pumping applications. In demanding facilities, reliability and energy efficiency directly impact uptime, maintenance costs, and total cost of ownership. This water-cooled design maintains stable temperatures under continuous operation, enabling higher continuous output in hot environments. The motor complies with IE3 efficiency, IP55 enclosure, and IC71W insulation, while rugged bearings and a sturdy IMB5 IM3001 footprint support long service life in harsh plants. For process automation, water management, and material handling, the M3LP 500LC 4 delivers predictable performance, lower energy consumption, and reduced maintenance scheduling, helping OEMs and end users meet sustainability targets and improve overall equipment effectiveness (OEE).

Product Information

Extended Description

3GLP502530-BUK ABB: M3LP 500LC 4

ABB Type Designation

M3LP 500LC 4

Invoice Description

M3LP 500LC 4

Product Name

3-Phase squirrel cage motor

Product Type

3LP3__water_cooled_motor_IE3

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015399

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC71W

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 97.5 % | Partial Load (75%) 97.6 % | Partial Load (50%) 97.5 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

4

Two Speed Motor

No

Type of Duty

S1

Voltage Code

U

Frame Material

Welded Steel

Frame Size

500

Bearing

6330M/C3

Bearing NDE

6326M/C3

IM Class

IMB5 IM3001

Terminator Box Location

D-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

5950 kg

Gross Weight

5990 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature: Water-cooled construction and 4-pole design provide precise temperature control and stable output. Business Impact: Enables continuous operation at higher loads without derating, reducing downtime and boosting plant throughput. Application: Process automation and pumping systems in hot environments benefit from predictable performance and extended motor life. Feature: IP55 enclosure and IC71W insulation. Business Impact: Enhanced protection against dust, water spray, and moisture, lowering fault rates in challenging plant conditions. Application: Outdoor installations, dusty production lines, and chemical processing facilities require robust enclosure integrity. Feature: IE3 efficiency with full-load and partial-load performance around 97.5–97.6% efficiency. Business Impact: Lower energy bills and improved sustainability metrics, contributing to lower total cost of ownership. Application: Continuous-duty conveyors and fans in energy-conscious facilities. Feature: Frame 500, bearing set 6330M/C3 and NDE 6326M/C3 with IMB5 IM3001 mounting. Business Impact: Reduced vibration, longer bearing life, and easier maintenance planning. Application: Heavy machinery, mills, and material handling systems where reliability matters. Feature: High-altitude (1000 m) and ambient temperature (40 °C) tolerance with 4-pole, voltage code U, and S1 duty. Business Impact: Simplified global deployment with fewer derating concerns and smoother installation across varying sites. Application: International production lines and multi-site automation deployments benefit from universal suitability. Feature: D-End right-side terminal box and Finland-origin manufacturing with robust mechanical build. Business Impact: Easier wiring, quicker installation, and traceable supply chain with strong regional support. Application: OEM integrations and retrofit projects requiring dependable sourcing and service availability.

Get a Quick Quote for a ABB 3GLP502530-BUK

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GLP502530-BUK?

Enquire Now

FAQs

The M3LP 500LC 4 uses a robust IMB5 IM3001 mounting class with a 500 frame and a D-End right-side terminator box. It is designed for base mounting and aligns with standard 500 mm frame footprints, simplifying retrofit into existing plant layouts. Ensure adequate coolant plumbing for the water-cooled design and confirm voltage code U and duty S1 specifications are consistent with your site power and continuous operation requirements.

Rated as IE3, the motor delivers high efficiency with Full Load (100%) around 97.5% and Partial Load (75%) near 97.6% (Partial Load 50% also ~97.5%). Its 4-pole design provides nominal speed suitable for conveyors and pumps, while IC71W insulation supports long service life in challenging environments. These figures translate to measurable energy savings in continuous-duty applications.

Yes. With IP55 protection and an ambient tolerance of up to 40 C plus operation up to 1000 m, the M3LP 500LC 4 is well-suited for dusty floors, humid plants, and outdoor installations. The IC71W insulation and rugged bearings further enhance reliability in demanding automation environments such as metalworking, mining, and chemical processing.

This motor features IP55 protection, IC71W insulation, and IC standard designations, along with a robust frame and 4-pole configuration for continuous load. It is suitable for international deployment and aligns with typical industrial procurement criteria, contributing to safer operation and regulatory compliance in automated facilities.

Water cooling stabilizes motor temperatures, reducing thermal derating and enabling longer duty cycles between maintenance events. This lowers energy losses, extends bearing life, and reduces fan-driven cooling losses common in air-cooled designs. For OEMs and end users, the result is improved uptime, lower maintenance costs, and a faster return on investment in process-critical equipment.