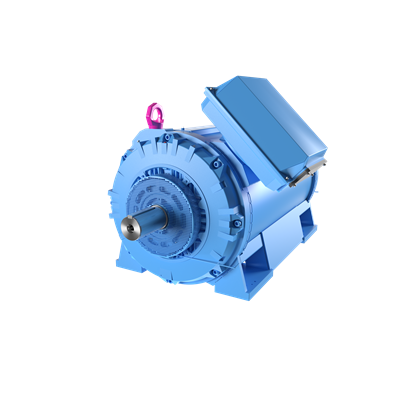

ABB 3GLP503510-LUK 3-Phase Squirrel Cage Motor - IP55

Part Number: 3GLP503510-LUK

Quick Summary

ABB 3GLP503510-LUK 3-Phase Squirrel Cage Motor delivers reliable, efficient drive for heavy-duty pumps and fans in industrial facilities. Engineers often struggle with heat, downtime, and energy costs when running high-power motors in harsh environments. This ABB motor combines IP55 protection, IC LF insulation, and IE3 efficiency to meet demanding industrial standards. Designed for water-cooled operation with a robust welded frame and 6 poles, it enables predictable maintenance, lower energy use, and easier procurement for OEMs and maintenance teams. Its S1 continuous-duty capability and wide ambient tolerance support long life in facilities with limited cooling capacity. This makes it suitable for pumps, fans, and conveyors in process plants.

Product Information

Extended Description

3GLP503510-LUK ABB: No Description Available

ABB Type Designation

M3LP 500LA 6

Product Name

3-Phase squirrel cage motor

Product Type

3LP3__water_cooled_motor_IE3

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015399

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC71W

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 97.3 % | Partial Load (75%) 97.5 % | Partial Load (50%) 97.4 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

6

Two Speed Motor

No

Type of Duty

S1

Voltage Code

U

Frame Material

Welded Steel

Frame Size

500

Bearing

6330M/C3

Bearing NDE

6326M/C3

IM Class

IMB3 IM1001

Terminator Box Location

D-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

5200 kg

Gross Weight

5240 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Water cooling in the 3GLP503510-LUK enables higher power density and sustained operation under heavy load, reducing temperature-related losses and minimizing downtime. This directly translates to measurable energy savings and improved equipment uptime for pumps and fans in demanding environments. The IE3 efficiency rating paired with real-world full-load and partial-load performance data (97.3% at 100% load, 97.5% at 75%, 97.4% at 50%) supports lower operating costs and a lower total cost of ownership for continuous processes. IP55 protection and ICLF insulation protect the windings from dust, moisture, and heat, ensuring reliability in outdoor or semi-enclosed installations and around hot processes. Frame size 500 with welded steel construction and IMB3 IM1001 mounting provides robust support and straightforward installation in OEM builds. The six-pole, 3-phase design with a D-End right-side terminator box simplifies wiring, while the 1000 m altitude and 40 °C ambient tolerance expand application scope in large facilities. Direction of rotation on both sides and the standard voltage code U enable flexible integration with existing power architectures. With a product net weight of 5200 kg and a compact, durable bearing arrangement (6330M/C3 and 6326M/C3), maintenance planning becomes predictable and lifecycle costs are reduced. This motor is well-suited for continuous-duty applications like process pumps, material handling conveyors, and demanding cooling fans, where reliability and efficiency drive productivity.

Get a Quick Quote for a ABB 3GLP503510-LUK

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GLP503510-LUK?

Enquire Now

FAQs

Yes. This motor uses a 3-phase configuration with Voltage Code U and a standard frame size 500. Its D-End right-side terminator box and IMB3 IM1001 mounting simplify integration with common VFDs and control panels. Always verify your specific drive compatibility and connector standards to ensure seamless commissioning.

IE Class Data shows Full Load (100%) at 97.3% efficiency, Partial Load (75%) at 97.5%, and Partial Load (50%) at 97.4%. These figures support energy savings across typical operating profiles and help justify lifecycle costs for continuous-duty applications.

Absolutely. The water-cooled design enables higher power density and cooler running temperatures, which is advantageous in high-load pumps, fans, and conveyors in process plants. Its 6-pole, frame 500 construction, IP55 protection, and ambient tolerance up to 40 °C make it suitable for challenging environments common in steel mills and heavy industrial facilities.

The motor features IP55 protection, IC LF insulation, and IC71W insulation class, along with IE3 efficiency. It is designed for S1 continuous duty and is built to endure demanding industrial conditions, including heat and dust exposure, while maintaining reliable performance.

With welded steel frame, durable bearings (6330M/C3 and 6326M/C3), and a robust 6-pole design, maintenance intervals can be planned predictably, reducing unplanned downtime. The motor’s weight, origin from Finland, and standard dimensions streamline spare parts inventory and procurement, delivering a favorable total cost of ownership for OEMs and maintenance teams.