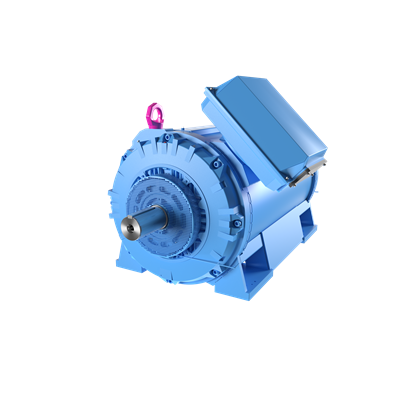

ABB 3GLP503520-LUK 3-Phase Motor - IE3, IP55

Part Number: 3GLP503520-LUK

Quick Summary

ABB 3GLP503520-LUK 3-Phase motor drives heavy-duty industrial processes with reliable cooling for continuous operation. In demanding facilities, inadequate cooling or sealing can lead to unplanned downtime and reduced throughput; this motor mitigates those risks with a water-cooled design and rugged enclosure. It emphasizes energy efficiency and protective capability by delivering IE3-class performance, IP55 ingress protection, and a robust insulation system suitable for challenging environments. The combination of standard 3-phase compatibility and ABB’s drive ecosystem supports streamlined procurement, improved maintenance planning, and predictable total cost of ownership for industrial manufacturers and process engineers alike.

Product Information

Extended Description

3GLP503520-LUK ABB: No Description Available

ABB Type Designation

M3LP 500LB 6

Product Name

3-Phase squirrel cage motor

Product Type

3LP3__water_cooled_motor_IE3

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015399

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC71W

IE Class Data (50 Hz)

IE Class NA | Full Load (100%) 97.4 % | Partial Load (75%) 97.6 % | Partial Load (50%) 97.5 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

6

Two Speed Motor

No

Voltage Code

U

Frame Material

Welded Steel

Frame Size

500

Bearing

6330M/C3

Bearing NDE

6326M/C3

IM Class

IMB3 IM1001

Terminator Box Location

D-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

5650 kg

Gross Weight

5690 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Feature → Business Impact → Application: The 3GLP503520-LUK employs IE3 energy efficiency, reducing operating costs by minimizing electrical losses in continuous-duty drives, which translates to lower utility bills for pumping and processing systems in heavy industry. This supports a measurable improvement in overall plant efficiency and can justify modernization projects in mining, steel, and water treatment facilities. Feature → Business Impact → Application: IP55 protection guards against dust ingress and water exposure, enabling reliable operation in outdoor skid-mounted setups, wash-down areas, or damp plant floors, reducing maintenance frequency and downtime for pumps and fans. Feature → Business Impact → Application: A 6-pole, 500-frame design offers favorable starting torque and efficient load handling for conveyors, mixers, and large fans, delivering smoother control and reduced mechanical stress under peak demand. Feature → Business Impact → Application: Water-cooled cooling enhances thermal management at high ambient temperatures (40 °C) and altitudes up to 1000 m, enabling sustained performance in hot plants and remote facilities where cooling capacity is critical. Feature → Business Impact → Application: 6330M/C3 and 6326M/C3 bearings with IMB3 IM1001 classification extend bearing life and reduce lubrication-related maintenance, improving uptime in continuous-running industrial drives such as rolling mills or processing lines. Feature → Business Impact → Application: D-End right-side terminator box placement simplifies wiring, panel layout, and service access during retrofit projects, supporting faster commissioning and easier field maintenance in retrofits or new installations. Feature → Business Impact → Application: The welded steel frame and 500 frame size provide robust rigidity and straightforward mounting in tight spaces, while 0 pallet packaging and heavy net weight considerations inform crane/rigging planning for shipping and installation teams in large-scale facilities.

Get a Quick Quote for a ABB 3GLP503520-LUK

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GLP503520-LUK?

Enquire Now

FAQs

This 500-frame, welded steel motor uses a D-End right-side terminator box and standard 3-phase voltage coding (Voltage Code U). With a weight of approximately 5.65 metric tons, plan crane-assisted installation and verify mounting alignment to minimize shaft misalignment. Ensure adequate cooling connections for the water-cooled system and confirm space for service access and terminal wiring in the control panel.

Key specs include 6 poles (high), IE3 efficiency, IP55 protection, and a 500 frame. It operates at ambient temperatures up to 40 °C and up to 1000 m altitude. Suitable for continuous-duty drives in heavy industrial processes such as conveyors, pumps, rolling mills, and large fans where robust protection and energy efficiency are essential.

Yes. The IP55 enclosure provides dust and water protection, making it suitable for outdoor installations, washdown areas, and damp plant environments. Coupled with the water-cooled design, it maintains performance under high thermal loads, reducing the risk of overheating in exposed or humid facilities.

The motor features IE3 energy efficiency and IP55 protection as key specifications. It also uses insulation class ICLF and equipment classifications such as IC71W, IMB3/IM1001, describing mounting and operational suitability. It is designed for use within standard industrial electrical environments and aligns with typical European and global motor requirements.

The combination of IE3 efficiency, robust IP55 protection, and a water-cooled design reduces energy consumption, thermal stress, and downtime. Bearings (6330M/C3 and 6326M/C3) and a rigid welded frame lower maintenance frequency and extend service life, delivering lower total cost of ownership and improved uptime for continuous-running drives in manufacturing plants.