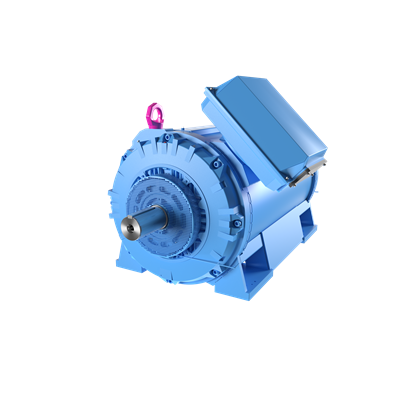

ABB 3GLP504530-RYK 3-Phase Squirrel Cage Motor - IE3

Part Number: 3GLP504530-RYK

Quick Summary

ABB 3GLP504530-RYK 3-Phase Squirrel Cage Motor is engineered for demanding industrial drives, delivering reliable power for pumps, fans, and compressors in process plants. This water-cooled, high-efficiency motor minimizes heat buildup and downtime in continuous operation environments. Operators struggle with overheating, frequent maintenance, and energy waste; this design targets those pain points with robust cooling, durable bearings, and proven IE3 efficiency. The motor combines IP55 protection, advanced insulation, and a heavy-duty welded steel frame for long service life in harsh conditions. With Finland-origin manufacturing and strict sourcing standards, it aligns with global procurement requirements while delivering strong total-cost-of-ownership benefits for OEMs and end users.

Product Information

Extended Description

3GLP504530-RYK ABB: No Description Available

ABB Type Designation

M3LP 500LC 8

Product Name

3-Phase squirrel cage motor

Product Type

3LP3__water_cooled_motor_IE3

Made To Order

No

Minimum Order Quantity

1 piece

Order Multiple

1 piece

Selling Unit of Measure

piece

Country of Origin

Finland (FI)

Customs Tariff Number

85015399

Electrical Data

Temperature Class Default

--

Altitude

1000 m

Ambient Temperature

40 °C

IC Class

IC71W

IE Class Data (60 Hz)

IE Class NA | Full Load (100%) 96.9 % | Partial Load (75%) 97.2 % | Partial Load (50%) 97.0 %

IP Class

IP55

Insulation Class

ICLF

Direction of Rotation

Both sides

Number of Poles (High)

8

Two Speed Motor

No

Voltage Code

Y

Frame Material

Welded Steel

Frame Size

500

Bearing

6330M/C3

Bearing NDE

6326M/C3

IM Class

IMB3 IM1001

Terminator Box Location

D-End right side

Package Level 1 Units

0 pallet (lift)

Product Net Weight

6000 kg

Gross Weight

0 kg

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

UNSPSC

26101100

Water-cooled design delivers exceptional heat rejection, enabling sustained full-load operation and reduced thermal derating in continuous-duty applications such as large pumps and compressors. Business impact: lower downtime and higher overall equipment effectiveness (OEE). Application: process industries where coolant efficiency and reliability are critical. The IE3 efficiency class reduces energy consumption in 24/7 operations, translating to measurable operating-cost savings and compliance with energy-efficiency regulations. Application: mining, chemical processing, and metalworking where energy intensity is high. IP55 protection and IC L F insulation provide robust resistance to dirt, moisture, and thermal cycling, extending motor life in dusty or humid environments and minimizing unscheduled maintenance. Application: packaging and water/wastewater facilities that demand dependable performance in challenging spaces. The 500 mm frame, welded steel construction, and 8-pole design yield high torque at startup with stable speed regulation, reducing motor stress and improving drive train longevity. Application: heavy-duty fans, conveyors, and large pumps where torque consistency matters. Durable bearings (6330M/C3, 6326M/C3) and IMB3 IM1001 mounting ensure reliable operation and easy alignment during installation. Application: OEM assemblies and retrofit projects requiring vetted mounting standards. D-End right side termination simplifies wiring layouts and field service, decreasing installation time. Application: integration with regional control cabinets and standardized motor starter configurations. The combination of 40 °C ambient tolerance and up to 1000 m altitude broadens site applicability, supporting offshore and onshore facilities with variable climate conditions. Application: global projects needing versatile motor performance across environments. WEEE Category 4 Large Equipment indication supports responsible end-of-life handling, reinforcing sustainability goals. These features collectively reduce total cost of ownership while delivering consistent, predictable performance in industrial environments.

Get a Quick Quote for a ABB 3GLP504530-RYK

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3GLP504530-RYK?

Enquire Now

FAQs

Yes. The motor uses a 3-phase power architecture with a voltage code of Y and offers reliable operation within typical industrial drive systems. Its IP55 rating, 40 °C ambient tolerance, and 1000 m altitude capability help ensure compatibility across regional electrical grids and plant layouts. The D-End right side termination simplifies wiring, accelerating installation and commissioning in OEM assemblies and retrofit projects.

Key specifications include an 8-pole design, frame size 500, and water-cooled configuration supporting IE3 efficiency. The motor delivers robust torque at startup with stable speed regulation and uses bearings 6330M/C3 and 6326M/C3 to minimize vibration and wear. Efficiency data at full load is aligned with IE Class NA performance, helping upper-management justify energy savings in continuous-duty applications.

This motor excels in heavy-duty pumps, large fans, and compressors in process industries such as mining, chemical processing, and steel manufacturing. Its water-cooled design and welded steel frame tolerate demanding service conditions, while the 500 frame and IP55 rating support reliable operation in environments with dust, moisture, or temperature variation.

The motor features IP55 protection, IC LF insulation class, and IE3 efficiency, aligning with common European and global efficiency standards. Direction of rotation is suitable for two-way drive configurations, and the insulation and protection ratings contribute to compliance with industry guidelines for safety and longevity in hazardous or damp environments.

The combination of high IE3 efficiency, robust bearings, and a durable welded frame reduces energy consumption and maintenance cycles. The D-End termination, reliable heat dissipation, and corrosion-resistant design minimize unexpected downtime. Over a project’s life, this translates to lower operating expenses and improved uptime, delivering a favorable total cost of ownership for OEMs and asset owners.