ABB 3HAC087369-001 Industrial Robot - IRB 1510

Part Number: 3HAC087369-001

Quick Summary

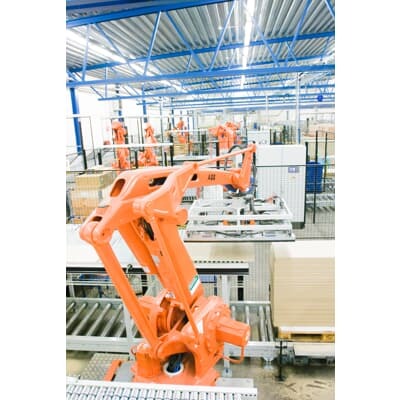

ABB 3HAC087369-001 Industrial Robot is designed for precise manipulation and dependable automation across automotive, electronics, and general manufacturing environments. The IRB 1510 enables fast, accurate part handling, welding, and assembly on demanding production lines, helping manufacturers reduce cycle times and boost throughput. Many teams struggle with integration, safety compliance, and changeover complexity; this robust platform simplifies cell design, lowers downtime, and streamlines maintenance. In typical deployments, CE conformity, IP-rated protection, and safe-systems interfaces are essential, while SIL-ready safety architectures can be selected to match risk assessments. By leveraging ABB’s control ecosystem and global service network, you gain predictable performance, scalable automation, and long-term support that translate into lower total cost of ownership and faster time-to-value.

Product Information

Extended Description

3HAC087369-001 ABB: IRB 1510

Country of Origin

Sweden (SE) | China (CN) | United States (US) | Czech Republic (CZ)

Invoice Description

IRB 1510

Minimum Order Quantity

1 piece

Selling Unit of Measure

piece

Order Multiple

1 piece

Quote Only

No

Made To Order

Yes

Customs Tariff Number

84795000

WEEE Category

4. Large Equipment (Any External Dimension More Than 50 cm)

Product Net Weight

320 kg

Gross Weight

0 kg

Product Net Height

1339 mm

Frame Size

Undefined

Product Name

-

ABB Type Designation

IRB 1510

Global Commercial Alias

IRB 1510

Feature → Business Impact → Application: The ABB IRB 1510-based platform delivers high-precision manipulation with robust integration into ABB control ecosystems, reducing cycle times and increasing throughput in machine tending and assembly cells; this translates to tangible productivity gains in automotive and electronics manufacturing. The robot’s Make-To-Order flexibility and a minimum order quantity of 1 piece streamline procurement for varied production runs, enabling rapid scale-up without overstock. Compatibility with multi-origin sourcing (Sweden, China, United States, Czech Republic) supports resilient supply chains and regional customization for global factories. With 320 kg net weight and a reachable 1339 mm net height, the unit supports adaptable robot cell layouts and easier integration into compact or constrained lines. This combination lowers integration risk and simplifies installation and commissioning, delivering faster time-to-value for robotic automation projects. Long-term serviceability and a global service network reduce lifecycle costs and optimize maintenance planning. The solution targets common industrial automation challenges, including cycle-time reduction, fault-tinding ease, and predictable performance in high-mix, low-to-mid volume environments, while addressing concerns about safety architecture and scalability for future line upgrades.

Get a Quick Quote for a ABB 3HAC087369-001

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 3HAC087369-001?

Enquire Now

FAQs

Yes. The IRB 1510-based system is designed to integrate with ABB control architectures and safety interfaces, enabling straightforward embedding into existing robot cells. When procuring, specify compatible ABB controllers and safety modules to ensure seamless communication, simplified commissioning, and consistent maintenance routines across the automation platform.

Key specifications include a product net weight of 320 kg and a product net height of 1339 mm, along with a minimum order quantity of 1 piece and a selling unit of measure as a piece. These metrics inform robot footprint planning, payload eligibility, and reach calculations critical for line layout and cycle-time optimization.

The IRB 1510 is well-suited for both high-precision welding and machine tending scenarios, thanks to reliable repeatability, robust build, and compatibility with ABB system software. For welding, ensure proper end-of-arm tooling and safety configurations. For machine tending, leverage ABB’s motion control and programming capabilities to optimize part handling and changeover times.

Certification details depend on the installation configuration. Typical deployments consider CE-style safety conformity and appropriate IP protection based on the chosen variant. SIL readiness and other safety certifications depend on the surrounding safety architecture and the integration with safeguarding devices, so confirm with the system integrator and ABB engineering team for your specific setup.

With Make-To-Order, lead times and customization are aligned to your production schedule, reducing risk of obsolescence. ABB’s global service network supports maintenance, spares, and upgrades, helping to maximize uptime. Expect improved throughput, reduced downtime, and a clear path to a lower total cost of ownership through scalable automation and proactive service planning.