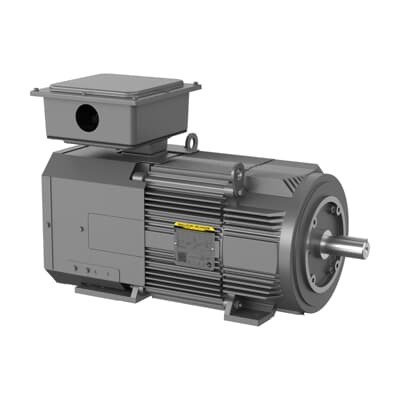

ABB ZDBRPM25604 RPMAC 60 HP Motor - TEBC Enclosure

Part Number: 7BZDBRPM25604

Quick Summary

ABB ZDBRPM25604 RPMAC 60 HP motor is a high-efficiency three-phase AC motor designed for demanding industrial drives such as conveyors, pumps, and fans in harsh plant environments. Operators face downtime due to heat buildup and misalignment, and this laminated frame with TEBC enclosure helps manage thermal stress and extend service intervals. It carries NEMA standards and CCSA US certification, with 60 HP at 460 V in a 3‑phase, 4‑pole configuration and a robust FL2578Z frame for continuous operation. This combination supports global procurement, with easy stocking and quick replacements across multiple warehouses, delivering reliable uptime and predictable maintenance costs.

Product Information

Extended Description

7BZDBRPM25604 ABB: AC VS Laminated Frame - RPMAC 60 Hp 460 V (ZDBRPM25604)

Configuration Only

No

Country of Origin

United States (US)

Lead Time

0 day

Made To Order

No

Product Sales Status

Active

Quote Only

No

Stocked At Warehouses

EGAUT001EXPU

Warranty Return

Product under warranty must be returned

Configuration Only

No

Country of Origin

United States (US)

Lead Time

0 day

Made To Order

No

Product Sales Status

Active

Quote Only

No

Stocked At Warehouses

GBINS001EXPU

Warranty Return

Product under warranty must be returned

Country of Origin

United States (US)

Lead Time

0 day

Made To Order

No

Product Sales Status

Active

Quote Only

No

Stocked At Warehouses

SGIND004EXPU

Warranty Return

Product under warranty must be returned

Country of Origin

United States (US)

Lead Time

0 day

Made To Order

No

Product Sales Status

Active

Quote Only

No

Stocked At Warehouses

USABB014EXPU

Warranty Return

Product under warranty must be returned

ABB Type Designation

60HP,1750,460V,FL2578,TEBC,F3

Ambient Temperature

40 °C

Base Speed

1800 r/min

Bearing

65BC03JPP30A, Ball

Bearing NDE

50BC03JPP30A

Brake Present

No

Brand / Label

Baldor-Reliance

Catalog Number

ZDBRPM25604

Certification Agency

CCSA US

Country of Origin

United States (US)

Customs Tariff Number

85015230

Dimension Diagram

616779-050

Drive End Flange Type

Standard

ETIM 7

EC001851 - Electric motor

Electrical Data

Enclosure Type

TEBC

Frame Material

Laminated

Frame Size

2578

Frequency (f)

60 Hz

Global Commercial Alias

ZDBRPM25604

Gross Volume

0 in³

Gross Weight

244.94 kg

Horsepower Rating UL/CSA

60.000 Hp

IDEA Granular Category Code (IGCC)

1328 >> Multi phase motor AC

Insulation Class

H

Invoice Description

60HP,1750,460V,FL2578,TEBC,F3

Made To Order

No

Medium Description

AC VS Laminated Frame - RPMAC, 60 HP, 1800/3600 RPM, Frame Size Fl2578Z, Standard Mounting, 3 Phase, TEBC Enclosure, 460 V, (ZDBRPM2

Minimum Order Quantity

1 piece

Motor Base Type

Foot Mounted

Motor Frame Size

FL2578Z

Mounting Orientation

Horizontal

Mounting Position

F3

Number of Phases

3

Number of Poles (High)

4

Order Multiple

1 piece

Output Power

60 Hp

Product Name

AC VS Laminated Frame - RPMAC

Product Net Depth / Length

0 in

Product Net Height

0 in

Product Net Weight

244.94 kg

Product Net Width

0 in

Product Type

Undefined

Quote Only

No

Rated Current (In)

75 A

Rated Speed

1775 r/min | 3540 r/min

Selling Unit of Measure

piece

Service Factor

1.00

Service Factor Percentage

1.00 %

Shaft Diameter

2.12 in

Shaft Grounding

Shaft Grounding

Short Description

60 HP, 1800/3600 RPM, Frame Size Fl2578Z, Standard, 3 PH, TEBC, 460 V

Standards

NEMA

Stocked At (Warehouses)

China | Alabama, United States | Alaska, United States

Synchronous Speed (vsyn)

1800 r/min

Type of Duty

Continuous

UNSPSC

26101115

Voltage Rating

460 V

Laminated frame construction reduces stray losses and minimizes heat buildup, delivering measurable efficiency gains and cooler operation in continuous duty tasks. This translates to lower energy consumption and longer bearing life, especially in hot production lines like conveyors and pumps. TEBC enclosure provides dust and moisture resistance, enhancing reliability in challenging environments and reducing maintenance downtime across chemical plants, food and beverage facilities, and outdoor installations. Rated at 60 HP, 460 V with three phases and four poles, the motor delivers stable speeds (1775 r/min / 3540 r/min) and easy drive integration, simplifying coupling selection and overall system efficiency. Foot-mounted, horizontal orientation (F3) with a 2.12 in shaft diameter enables straightforward installation and alignment with existing bases, minimizing retrofit risk. Stocked at multiple warehouses with 0-day lead time, this design supports fast procurement and project scheduling. Insulation Class H and robust bearings (65BC03JPP30A) ensure long service life in ambient temperatures up to 40 °C, while shaft grounding improves electrical safety during maintenance and servicing.

Get a Quick Quote for a ABB 7BZDBRPM25604

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB 7BZDBRPM25604?

Enquire Now

FAQs

Yes. This motor is designed for foot-mounted, horizontal installation (F3) with a 2.12 in shaft and frame FL2578Z, aligning with common Baldor-Reliance layouts. Confirm mounting footprint and coupling size during a retrofit to ensure precise alignment, but the standard mounting orientation simplifies replacement and minimizes downtime.

Key specs include 60 HP at 460 V, 3-phase input, and 4 poles with a rated current of 75 A. The motor supports synchronous speed of 1800 r/min and nominal speeds of 1775 r/min and 3540 r/min, enabling flexible drive configurations while maintaining consistent torque and performance in demanding processes.

Ideal for continuous-duty drives in conveyors, pumps, and fans operating in harsh environments. The TEBC enclosure, laminated frame, and NEMA-aligned design deliver reliable performance in manufacturing, processing, and material handling facilities, where uptime and energy efficiency are critical.

This motor aligns with NEMA standards and carries CCSA US certification, supporting compliance in US-based facilities. Insulation class is H, suitable for higher temperature operation, and the unit adheres to standard Baldor-Reliance product integration guidelines for safe, reliable use.

0-day lead times and multi-warehouse stocking reduce project delays and spare-part shortages, improving upfront ROI. The laminated frame and TEBC enclosure minimize heat-related wear, extend bearing life, and reduce maintenance intervals, while straightforward mounting and compatibility with existing bases shorten installation time and labor costs.