ABB EP2030K Control and Automation Board - CE

Part Number: EP2030K

Quick Summary

ABB EP2030K control and automation board enables integrated cabinet solutions for industrial automation enclosures. Many panel builders struggle with rear-panel configurations and accurate mounting in tall enclosures, which can slow projects and increase field rework. CE conformity, RoHS compliance, and REACH declarations ensure regulatory alignment while simplifying vendor audits for complex installations. The kit-style rear-panel enclosure provides modularity, reduces lead times, and supports scalable cabinet sizes from 2 m tall frames to compact control bays. Engineers benefit from a durable pickled steel body finished in orange peel with RAL 7035, delivering predictable corrosion protection and easy paint matching in live environments. This combination translates into repeatable assemblies, lower lifecycle costs, and smoother maintenance planning for automation projects.

Product Information

Extended Description

EP2030K ABB: Front/rear panel external cable container 2000x300mm (HxW)

Sub-Function 3

Rear panel

Configuration Type

4. Rear panel

Enclosure Type

Kit - rear panel

Mounting Type

Kit

Product Type

5B5B20B260

Surface Finishing

Orange Peel, RAL 7035

Material

Pickled steel sheet

Remarks

ETIM

RAL Number

RAL 7035 - Light Grey

RoHS Information

RoHS information

RoHS Date

20250108

REACH Declaration

REACH declaration

REACH Information

False - does not contain substances > 0.1 mass percentage

REACH Date

20250108

WEEE Category

Product Not in WEEE Scope

Environmental Information

IS2 Enclosures Technical Catalogue 2024

Product Net Width

294 mm

Product Net Height

1996 mm

Product Net Depth / Length

16 mm

Product Net Weight

7.980 kg

Reference Depth/Length

400 mm | 500 mm | 600 mm | 800 mm | 1000 mm

Reference Height

2000 mm

Reference Width

300 mm

Package Level 1 Units

1 piece

Package Level 1 Gross Weight

8.140 kg

Declaration of Conformity - CE

Declaration of Conformity IS2

Instructions and Manuals

1STM604121R0006

Data Sheet, Technical Information

IS2 Enclosures Technical Catalogue 2024

ETIM 8

EC002524 - Side-/back panel (enclosure/cabinet)

ETIM 9

EC002524 - Side-/back panel (enclosure/cabinet)

eClass

V11.1 : 27182101

Object Classification Code

U

Standards

See code for structure

Feature: Rear-panel kit architecture enables pre-assembled wiring trays and cable containers outside the现场, reducing installation time and wiring errors. Business Impact: Accelerates commissioning, improves reliability, and lowers on-site labor costs. Application: Ideal for ABB IS2 enclosure families in tall control cabinet projects. Feature: Durable pickled steel with orange-peel finish (RAL 7035) provides consistent corrosion resistance and easy color matching in industrial environments. Business Impact: Longer service life and reduced repainting during maintenance. Application: Suitable for harsh factory floors and automated lines. Feature: Precise dimensions and modular reference depths (400–1000 mm) with a wide height (2000 mm) and width (300 mm) footprint enable scalable configurations. Business Impact: Improves design predictability and stocking efficiency. Application: Fits a range of control panels from compact to tall enclosures. Feature: Kit mounting type and rear-panel emphasis streamline installation and service access. Business Impact: Simplifies retrofits and upgrades, lowering downtime. Application: Retrofit projects and new builds that require modular cabling access. Feature: Comprehensive compliance documentation (CE, RoHS, REACH) reduces audit effort and regulatory risk. Business Impact: Regulatory confidence and faster procurement cycles. Application: Automotive, process, and discrete manufacturing environments that demand traceable conformity. Feature: Documentation and catalog support (IS2 Enclosures Technical Catalogue 2024, ETIM/eClass classifications) enhances compatibility checks and parts sourcing. Business Impact: Reduces mis-orders and ensures consistent BOMs. Application: Engineering teams aligning with global standards for enclosure systems.

Get a Quick Quote for a ABB EP2030K

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB EP2030K?

Enquire Now

FAQs

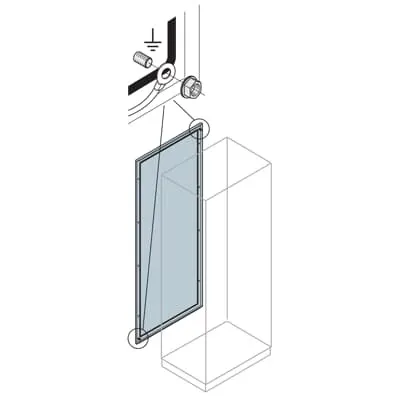

To install EP2030K, begin by verifying enclosure compatibility with the rear-panel kit and ensure mounting holes align with the IS2 frame. Pre-assemble the rear panel assembly off-site where possible, then secure the kit to the enclosure per the IS2 documentation. Route cables through the external container, connect grounding, and verify fit against reference dimensions (W 294 mm, H 1996 mm, D 16 mm). This approach minimizes field wiring errors and reduces commissioning time.

EP2030K features a net width of 294 mm, net height of 1996 mm, and net depth of 16 mm, with reference width 300 mm and reference height 2000 mm. It supports reference depths of 400, 500, 600, 800, and 1000 mm and is designed as a rear-panel kit for ABB IS2 enclosure families. The kit is mounted as a standalone rear panel, facilitating modular assembly and wiring access.

Yes. The EP2030K is specifically designed for tall cabinet applications, with a reference height of 2000 mm and a total width around 300 mm. Its rear-panel kit approach simplifies mounting and cable management in tall enclosures, supporting scalable architectures from standard to high-density automation cabinets while maintaining service access and safety clearances.

EP2030K carries CE conformity with the Declaration of Conformity IS2, RoHS compliance dated 20250108, and a REACH declaration indicating no substances over 0.1 mass percent. These certifications matter for regulatory compliance, safety audits, and supplier qualification, ensuring the enclosure is appropriate for global manufacturing environments and reducing compliance risk during inspections.

The EP2030K rear-panel kit reduces installation time and field wiring complexity, lowering commissioning labor and potential wiring faults. Its durable finish (RAL 7035), pickled steel construction, and modular design support longer service life with fewer repaint cycles. Overall, projects benefit from faster builds, easier maintenance, and predictable lifecycle costs in automation cabinet programs.