ABB TS4002 Control Board - CE Declaration of Conformity

Part Number: TS4002

Quick Summary

ABB TS4002 is a control board designed to streamline automation cabinet projects within IS2 enclosures. Engineers often face mounting complexity and integration delays when upgrading legacy frames, from wiring clashes to misaligned panels. This solution carries CE Declaration of Conformity, RoHS compliance, and REACH declarations to meet regulatory demands. By providing a pre-assembled mounting kit and IS2 compatibility, it reduces installation time and field fabrication costs. The design also supports scalable expansion with 16 accessory sections, delivering long-term value for evolving automation requirements.

Product Information

Extended Description

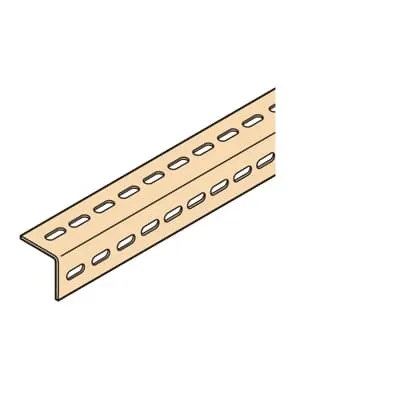

TS4002 ABB: N°2 cable rails W=1000mm

Sub-Function 3

Other

Suitable For

IS2 Enclosures for Automation

Suitable for Product Class

Control and Automation Board

Accessory Type

15. Distribution and earthing system

Mounting Type

Kit | Pre assembled

Product Type

5B5B30B340

Material

Pickled steel sheet

Options Provided

16. Sections for accessories

Remarks

ETIM

RoHS Information

RoHS information

RoHS Date

20250108

REACH Declaration

REACH declaration

REACH Information

False - does not contain substances > 0.1 mass percentage

REACH Date

20250108

WEEE Category

Product Not in WEEE Scope

Environmental Information

IS2 Enclosures Technical Catalogue 2024

Product Net Width

1000 mm

Product Net Height

50 mm

Product Net Depth / Length

50 mm

Product Net Weight

0.02 kg

Reference Depth/Length

300 mm | 400 mm | 500 mm | 600 mm | 800 mm | 1000 mm

Reference Height

1400 mm | 1600 mm | 1800 mm | 2000 mm | 2200 mm

Reference Width

400 mm | 600 mm | 800 mm | 1000 mm | 1200 mm | 1600 mm

Package Level 1 Units

1 piece

Package Level 1 Gross Weight

2.000 kg

Declaration of Conformity - CE

Declaration of Conformity IS2

Instructions and Manuals

1STM604121R0006

Data Sheet, Technical Information

IS2 Enclosures Technical Catalogue 2024

ETIM 8

EC002625 - Mounting accessories (enclosure/cabinet)

ETIM 9

EC002625 - Mounting accessories (enclosure/cabinet)

eClass

V11.1 : 27182807

Object Classification Code

U

Standards

See code for structure

IS2 enclosure compatibility enables rapid panel integration, reducing field fit issues and commissioning risk. Practically, this means fewer last-minute fabrications and shorter downtime during upgrades for automation lines. Deployment in IS2-based cabinets supports consistent data wiring, standardized mounting, and predictable thermal and mechanical performance, which speeds validation and start-up in both new installations and retrofits.\n\nPre-assembled mounting kit reduces on-site labor and misalignment errors. By delivering a ready-to-install framework, maintenance teams can complete panel assembly faster, decreasing project labor costs and accelerating time-to-value. This is particularly valuable for high-mix, high-demand production environments where changeovers must be minimized without compromising safety or accessibility.\n\nPickled steel sheet construction provides durable, corrosion-resistant mounting hardware that holds up under vibration and temperature variation common in industrial settings. The material choice translates into longer service life, lower replacement frequency, and reduced maintenance costs over the equipment lifecycle. For engineers, this means dependable enclosure infrastructure that maintains alignment and electrical performance across extended operation.\n\nWide product width with versatile reference depths, heights, and widths enables modular customization without bespoke fabrication. The 50 mm net height and depth contribute to a compact footprint, while reference options (300–1000 mm length, 1400–2200 mm height, 400–1600 mm width) support scalable configurations. This flexibility simplifies procurement and planning for multi-line automation projects.\n\nComprehensive regulatory and environmental documentation supports risk management and audit readiness. CE declaration of conformity, RoHS and REACH compliance, and WEEE classification align with global standards and internal compliance programs. Data sheets and installation manuals ensure correct installation, reduce support calls, and improve ROI through predictable performance.

Get a Quick Quote for a ABB TS4002

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB TS4002?

Enquire Now

FAQs

Yes. TS4002 is specified as Suitable For IS2 Enclosures for Automation and ships as a Kit | Pre assembled, designed to fit IS2 frames without custom fabrication. This compatibility reduces wiring misalignment and panel rework, and the 1000 mm width with adjustable reference lengths supports a wide range of IS2 cabinet configurations. Always verify reference dimensions against your exact enclosure model.

Key specifications include a pickled steel sheet construction, 1000 mm product net width, 50 mm net height, 50 mm net depth, and a reference depth/length range of 300–1000 mm plus reference height range of 1400–2200 mm. The product ships pre-assembled as a mounting kit and is aligned with RoHS and REACH declarations for responsible material usage.

Absolutely. TS4002 is designed as a control and automation board for IS2 enclosures, with a mounting kit that supports rapid deployment in industrial lines, packaging machines, and process-control panels. Its modular accessory sections and scalable dimensions help accommodate evolving line configurations without rework, enabling faster time-to-value in production environments.

The TS4002 carries a CE Declaration of Conformity, RoHS information with a 20250108 RoHS date, and a REACH declaration with a 20250108 REACH date. WEEE classification indicates the product is not in the WEEE scope. These certifications support regulatory compliance, supplier audits, and sustainability reporting across global manufacturing sites.

The pre-assembled mounting kit and IS2 compatibility reduce field assembly time and labor costs, shortening commissioning windows and limiting downtime. Material choice and robust construction lower maintenance frequency, while the 16 accessory sections enable future expansions without redesign, yielding a favorable total cost of ownership in automation projects.