ABB ZN1001 Control and Automation Board - CE Certified

Part Number: ZN1001

Quick Summary

ZN1001 ABB control and automation board enables compact, reliable control within IS2 enclosure systems for automation. This solution helps engineers streamline panel assembly and retrofit projects by bundling mounting hardware and a robust enclosure interface in a single kit. The design carries CE Declaration of Conformity, RoHS compliance with the 20250108 date, and REACH information indicating no substances above 0.1% mass. These certifications reduce risk during audits and supply chain handoffs. By pairing durable pickled steel sheet construction with adjustable dimensions, it also delivers long-term cost savings and simplified field service, aligning with proactive maintenance strategies and scalable automation deployments.

Product Information

Extended Description

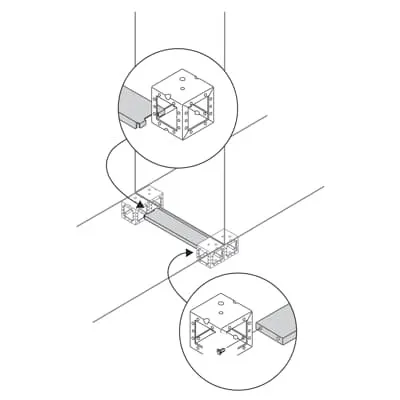

ZN1001 ABB: N.2 support flanges for cables W=1000

Sub-Function 3

Base front/back

Suitable For

IS2 Enclosures for Automation

Suitable for Product Class

Control and Automation Board

Accessory Type

6. Flanges

Mounting Type

Kit | Pre assembled

Product Type

5B5B30B330

Material

Pickled steel sheet

Options Provided

Flange in depth for structure reinforcement

Remarks

ETIM

RoHS Information

RoHS information

RoHS Date

20250108

REACH Declaration

REACH declaration

REACH Information

False - does not contain substances > 0.1 mass percentage

REACH Date

20250108

WEEE Category

Product Not in WEEE Scope

Environmental Information

IS2 Enclosures Technical Catalogue 2024

Product Net Width

85 mm

Product Net Height

40 mm

Product Net Depth / Length

800 mm

Product Net Weight

2.2230 kg

Reference Depth/Length

1000 mm

Reference Height

1400 mm | 1600 mm | 1800 mm | 2000 mm | 2200 mm

Reference Width

400 mm | 600 mm | 800 mm | 1000 mm | 1200 mm

Package Level 1 Units

1 piece

Package Level 1 Gross Weight

2.446 kg

Declaration of Conformity - CE

Declaration of Conformity IS2

Instructions and Manuals

1STM604121R0006

Data Sheet, Technical Information

IS2 Enclosures Technical Catalogue 2024

ETIM 8

EC000721 - Base/base element (enclosure/cabinet)

ETIM 9

EC000721 - Base/base element (enclosure/cabinet)

eClass

V11.1 : 27182003

Standards

See code for structure

Feature Mounting Type Kit | Pre assembled. Business Impact Reduces installation time and minimizes wiring and mounting errors by delivering a ready-to-install mounting solution for IS2 Enclosures for Automation. Application Suitable for fast panel integration in automation projects and retrofit work. Long-tail keywords integrated: IS2 Enclosures for Automation, pre-assembled mounting kit, enclosure mounting solution. Feature Material Pickled steel sheet. Business Impact Delivers robust enclosure backbone with corrosion resistance for harsh industrial environments. Application Ideal for long-term operation in manufacturing and process facilities. Feature Dimensions Net Width 85 mm; Net Height 40 mm; Net Depth 800 mm. Business Impact Enables compact footprint with predictable space planning and modular configuration. Application Supports flexible installation in narrow panels and multi-bay panels. Feature Reference Dimensions Depth 1000 mm; Height options 1400–2200 mm; Width options 400–1200 mm. Business Impact Supports scalable configurations to match customer enclosure layouts and future upgrades. Application Facilitates standardization across OEMs and maintenance cycles. Feature Accessory Type 6. Flanges; Options Provided Flange in depth for structure reinforcement. Business Impact Improves cable management and structural reinforcement, reducing vibration and wear. Application Enhances rigidity for heavy cables and dynamic loads. Feature Mounting Type Kit | Pre assembled; Suitable For IS2 Enclosures for Automation; Product Type 5B5B30B330. Business Impact Simplifies procurement and engineering planning with a single, compatible kit. Application Reduces BOM complexity and accelerates quote-to-order cycles. Feature Material Compliance RoHS Information; RoHS Date 20250108; REACH Declaration; REACH Information False - does not contain substances > 0.1 mass percentage. Business Impact Minimizes regulatory risk and audit findings. Application Supports compliant device packaging and disposal strategies. Feature Documentation and Manuals 1STM604121R0006; Data Sheet IS2 Enclosures Technical Catalogue 2024; ETIM and eClass cross-references. Business Impact Provides quick access to installation guidance and compatible standards for engineers. Application Improves maintenance planning and technical onboarding.

Get a Quick Quote for a ABB ZN1001

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB ZN1001?

Enquire Now

FAQs

ZN1001 is delivered as a mounting kit with pre assembled options, plus N.2 support flanges for cables (W=1000). This setup reduces on-site assembly steps and minimizes mounting errors, speeding panel completion for IS2 Enclosures for Automation and enabling faster commissioning.

The product features net dimensions of 85 mm width, 40 mm height, and 800 mm depth, with reference depths/heights: 1000 mm and 1400–2200 mm, and widths from 400–1200 mm. It is designed for IS2 Enclosures for Automation and is compatible with the Base/base element ETIM classification.

ZN1001 carries a CE Declaration of Conformity and RoHS compliance dated 20250108, along with REACH information indicating no substances above 0.1 mass%. WEEE category indicates the product is not in WEEE scope. These certifications simplify audits and supplier qualification.

Yes, ZN1001 is specifically suitable for IS2 Enclosures for Automation. Its pre-assembled mounting kit with six flanges enhances rigidity and cable management, reducing vibration-related wear and improving reliability in demanding environments. The pickled steel construction adds durability for long service life.

Installation is supported by the 1STM604121R0006 manual and the IS2 Enclosures Technical Catalogue 2024 data sheet. These materials provide step-by-step assembly guidance, wiring layouts, and recommended mounting practices to speed up onboarding and ensure correct integration.