ABB ZN6002 Control and Automation Board - IS2 Enclosures CE

Part Number: ZN6002

Quick Summary

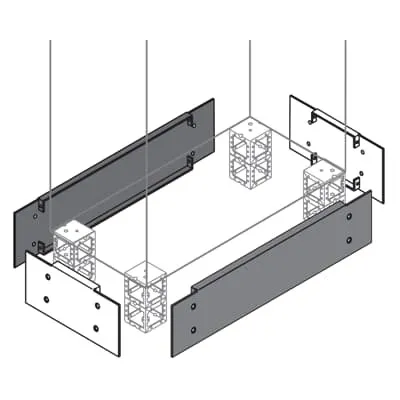

ZN6002 is a control and automation board kit designed for IS2 enclosures in automation installations. Frames and mounting kits often require custom fabrication and on-site adjustments, delaying projects. The solution carries CE conformity, RoHS compliance, and REACH declarations to meet regulatory and environmental requirements, with a documented declaration of conformity. By enabling pre-assembled mounting with six flanges and front/back access, it accelerates installation, reduces wiring errors, and lowers total cost of ownership for panel builders and OEMs. This ABB offering also aligns with ABB IS2 Enclosures Technical Catalogue guidance, ensuring compatibility with standard ABB enclosure families and facilitating scalable automation upgrades. Engineers benefit from consistent part numbers and faster changeovers.

Product Information

Extended Description

ZN6002 ABB: N.2 plinth flanges 200x600mm HxW

Sub-Function 3

Base front/back

Suitable For

IS2 Enclosures for Automation

Suitable for Product Class

Control and Automation Board

Accessory Type

6. Flanges

Mounting Type

Kit | Pre assembled

Product Type

5B5B30B330

Material

Pickled steel sheet

Options Provided

Blind flanges front/back/side H=200 mm

Remarks

ETIM

RoHS Information

RoHS information

RoHS Date

20250108

REACH Declaration

REACH declaration

REACH Information

False - does not contain substances > 0.1 mass percentage

REACH Date

20250108

WEEE Category

Product Not in WEEE Scope

Environmental Information

IS2 Enclosures Technical Catalogue 2024

Product Net Width

205 mm

Product Net Height

63 mm

Product Net Depth / Length

620 mm

Product Net Weight

3.2980 kg

Reference Depth/Length

300 mm | 400 mm | 500 mm | 600 mm | 800 mm | 1000 mm

Reference Height

1400 mm | 1600 mm | 1800 mm | 2000 mm | 2200 mm

Reference Width

400 mm | 600 mm | 800 mm | 1000 mm | 1200 mm

Package Level 1 Units

1 piece

Package Level 1 Gross Weight

3.628 kg

Declaration of Conformity - CE

Declaration of Conformity IS2

Instructions and Manuals

1STM604121R0006

Data Sheet, Technical Information

IS2 Enclosures Technical Catalogue 2024

ETIM 8

EC000721 - Base/base element (enclosure/cabinet)

ETIM 9

EC000721 - Base/base element (enclosure/cabinet)

eClass

V11.1 : 27182003

Standards

See code for structure

IS2 enclosure compatibility and mounting efficiency reduce integration risk and wiring errors, enabling faster panel builds and easier future upgrades. Business impact: shorter commissioning times and predictable maintenance cycles in manufacturing automation environments. Application: control panels for conveyors, machine tools, and packaging lines benefit from standardized six-flange mounting and pre-assembled kit design, compatible with front/back access for clean wiring and diagnostics.Durable construction using pickled steel sheet enhances long-term reliability in harsh industrial conditions, reducing corrosion-related downtime and replacement costs. Business impact: lower total cost of ownership and improved panel longevity. Application: outdoor or wash-down environments where enclosure integrity is critical.Modular dimensions and reference options support scalable panel design, minimizing rework when expanding lines. Business impact: design flexibility translates to faster spec-to-build cycles. Application: IS2 enclosure families with widths from 400 to 1200 mm and heights from 1400 to 2200 mm, enabling rapid configuration for varied control tasks.Pre-assembly and included accessories—such as blind flanges front/back/side (H=200 mm)—eliminate on-site drilling and field modifications. Business impact: reduces installation time and field labor costs. Application: OEMs delivering standardized panels across several models gain predictability and reproducibility.Regulatory and standards alignment—CE Declaration of Conformity, RoHS and REACH compliance—provides risk mitigation and smoother audits. Business impact: faster approval cycles and easier supplier qualification. Application: regulated industries and corporate sustainability programs benefit from verified material compliance and traceability.

Get a Quick Quote for a ABB ZN6002

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB ZN6002?

Enquire Now

FAQs

To install ZN6002, align the pre-assembled mounting kit with the IS2 enclosure base, attach the six flanges to the frame, and secure using the included fasteners. Use the front/back access points for wiring and component access, then reference the enclosure dimensions (W, H, D) to ensure a proper fit. Follow the provided installation code 1STM604121R0006 for step-by-step guidance.

Yes. ZN6002 supports front/back mounting and includes options for blind flanges on the front, back, and sides (H=200 mm), enabling clean terminations and reduced ingress. The kit is designed as a pre-assembled solution to minimize on-site modifications and ensure secure, standards-compliant mounting in IS2 enclosures.

ZN6002 carries CE conformity, RoHS compliance, and REACH declarations, ensuring regulatory compliance and environmental stewardship. These certifications support audit readiness, reduce risk in regulated industries, and align with global supply chain expectations for enclosure components used in automation systems.

ZN6002 uses a compact net width of 205 mm, height of 63 mm, and depth of 620 mm, with a net weight of 3.298 kg. Reference depth/length options include 300, 400, 500, 600, 800, and 1000 mm, while reference heights span 1400 to 2200 mm to fit a range of IS2 enclosure configurations.

The pre-assembled mounting kit reduces installation time and field wiring errors, lowering labor costs and commissioning risk. Durable pickled steel construction minimizes corrosion-related downtime, while standardized flanges simplify future upgrades and spare-parts management, delivering faster payback through reduced maintenance and more reliable, scalable automation panels.