ABB ZU2101 Other/Miscellaneous - IS2 Enclosures

Part Number: ZU2101

Quick Summary

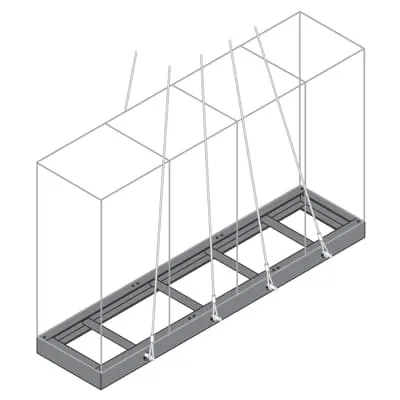

ZU2101 is a control and automation board designed for ABB System pro E IS2 enclosures. Engineers often struggle with integration and mounting within IS2 System pro E control enclosures, causing project delays. This solution carries CE conformity, RoHS and REACH declarations, plus ETIM and eClass classifications to streamline compliance and sourcing. The kit is provided as a pre-assembled plinth with a single unit length option, easing installation planning. With fixed dimensions—800 mm width, 200 mm height, 1000 mm depth—and pickled steel construction, you gain durability, repeatable fit, and lower field rework. This aligns with IS2 enclosures Technical Catalogue 2024 and supports scalable enclosure configurations for future-proof deployments.

Product Information

Extended Description

ZU2101 ABB: Entire Striph=200xswitc.Bat.Um=M Mounted

Sub-Function 3

Base front/back

Suitable For

Automation and Control Enclosures (System pro E control) - IS2

Suitable for Product Class

Automation and Control Enclosures (System pro E control)

Accessory Type

7. Plinth

Mounting Type

Kit | Pre assembled

Product Type

5B5B35B335

Material

Pickled steel sheet

Options Provided

Single plinth (unit of measure for the order: METRE)

Remarks

ETIM

RoHS Information

RoHS information

RoHS Date

20250108

REACH Declaration

REACH declaration

REACH Information

False - does not contain substances > 0.1 mass percentage

REACH Date

20250108

WEEE Category

Product Not in WEEE Scope

Environmental Information

IS2 Enclosures Technical Catalogue 2024

Product Net Width

800 mm

Product Net Height

200 mm

Product Net Depth / Length

1000 mm

Product Net Weight

13.9 kg

Reference Depth/Length

300 mm | 400 mm | 500 mm | 600 mm | 800 mm | 1000 mm

Reference Height

1400 mm | 1600 mm | 1800 mm | 2000 mm | 2200 mm

Reference Width

400 mm | 600 mm | 800 mm | 1000 mm | 1200 mm

Package Level 1 Units

1 piece

Package Level 1 Gross Weight

13.983 kg

Declaration of Conformity - CE

Declaration of Conformity IS2

Instructions and Manuals

IS2 instruction handbook 2024

Data Sheet, Technical Information

IS2 Enclosures Technical Catalogue 2024

ETIM 8

EC000721 - Base/base element (enclosure/cabinet)

ETIM 9

EC000721 - Base/base element (enclosure/cabinet)

eClass

V11.1 : 27182003

Object Classification Code

U

Standards

See code for structure

Feature: Pre-assembled plinth kit for IS2 System pro E control enclosures. Business Impact: Reduces on-site assembly time and misalignment, improving installation reliability. Application: Ideal for automation enclosure projects where fast deployment is critical and standardization matters. Feature: Material made from pickled steel sheet. Business Impact: Enhanced durability in harsh industrial environments, lowering maintenance and replacement costs. Application: Common in rugged control cabinet applications and long-life deployments in manufacturing facilities. Feature: Mounting Type Kit | Pre assembled. Business Impact: Simplifies procurement and ensures repeatable fit across multiple enclosure configurations. Application: Scales from small to large IS2 systems with predictable BOM and reduced setup complexity. Feature: Options Provided Single plinth (unit of measure for the order: METRE). Business Impact: Streamlines ordering and inventory planning, reducing waste and stockouts. Application: Enables modular expansion and consistent configurations across projects. Feature: Compliance and certifications RoHS, REACH, CE. Business Impact: Minimizes regulatory risk and expedites audits, improving supplier qualification and traceability. Application: Essential for ISO and industry-standard audits in automation environments. Feature: Dimensional compatibility Reference Depth/Length options and Reference Height/Width. Business Impact: Ensures fit across a range of ABB IS2 enclosure sizes with reduced rework. Application: Facilitates scalable design, standardizing enclosure footprints and mounting depths. Feature: Product weight 13.9 kg. Business Impact: Predictable handling and shipment planning; supports structural calculations for cabinet loads. Application: Field installation planning and crane/lift considerations for heavy-duty enclosures. Feature: Documentation IS2 Enclosures Technical Catalogue 2024 and Instructions manual. Business Impact: Accelerates commissioning and training through authoritative references. Application: Procurement, commissioning, and maintenance workflows in industrial plants.

Get a Quick Quote for a ABB ZU2101

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in ABB ZU2101?

Enquire Now

FAQs

ZU2101 is designed specifically for ABB System pro E IS2 enclosure families, delivering a pre-assembled plinth that matches IS2 mounting standards. Its mounting kit format reduces on-site customization, ensuring predictable alignment with enclosure bases and mounting rails while enabling fast, repeatable installations across multiple cabinet configurations.

Key specs include a width of 800 mm, height of 200 mm, depth of 1000 mm, and a net weight of 13.9 kg. The material is pickled steel sheet, and the product is offered as a pre-assembled kit (Single plinth). It supports IS2 automation enclosures and carries CE, RoHS, and REACH conformance with reference sizes for modular expansion.

Yes. ZU2101 is purpose-built for automation and control enclosures using ABB System pro E IS2 standards. Its pre-assembled plinth design, robust steel construction, and standardized dimensions ensure reliable performance in harsh industrial settings, while maintaining compatibility with IS2 catalogue specifications and installation practices.

ZU2101 carries a Declaration of Conformity for CE, RoHS information with a 20250108 RoHS date, and REACH declarations, including information about substances below regulatory thresholds. It also aligns with ETIM and eClass classifications, and is noted as WEEE category non-applicable to WEEE scope, supporting regulatory audits and safe disposal pathways.

The plinth kit reduces on-site assembly time, minimizes mounting errors, and simplifies BOM planning, contributing to lower total project costs and faster commissioning. Its durable pickled steel construction withstands industrial use, decreasing repair cycles and facilitating scalable enclosure configurations for future projects.