Eaton Crouse-Hinds ECP040604 Enclosure - Hazardous Locations

Part Number: ECP040604

Manufacturer

Eaton Crouse-Hinds

Part number

ECP040604

Quick Summary

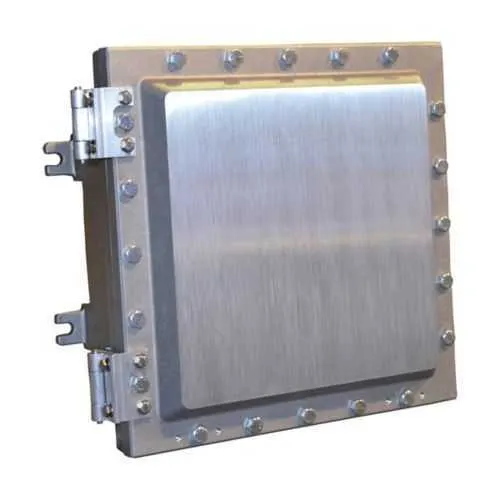

The Eaton Crouse-Hinds ECP enclosure is a rugged, explosionproof housing designed for hazardous locations in process and power facilities. This enclosure helps prevent downtime from dust ingress, moisture, and corrosive atmospheres that threaten control circuits and power distribution. It supports NEC/CEC hazardous-location requirements and offers protection suitable for Class I, Division 1 and 2; Class II, Division 1 and 2; Class III environments, with compatible NEMA ratings 3, 3R, 4, 7, and 9. Built from copper-free aluminum, it combines lightweight strength with corrosion resistance. Bolt-on mounting feet simplify surface or equipment-frame installation and enable rapid retrofits, minimizing commissioning time while maintaining lockout-tagout readiness and long-term maintenance efficiency. With a compact 4x6x4 inch footprint and rounded cover, it fits tight spaces on machinery or in control cabinets. Engineers value the balance of protection, weight, and serviceability when planning upgrades or expansions.

Product Information

Extended Description

ECP040604 Eaton Crouse-Hinds: Eaton Crouse-Hinds series ECP enclosure, Rounded cover, 4-5/8" depth, 4" x 6" x 4", Copper-free aluminum, Bolt-on mounting feet

Product Name

Eaton Crouse-Hinds series ECP enclosure

Catalog Number

ECP040604

Product Length/Depth

8.34 in

Product Height

10.34 in

Product Width

6.13 in

Product Weight

16 lb

UPC

662276309814

Area classification

Hazardous/Classified Locations

Standards type

NEC/CEC

NEC hazardous rating

Class I, Division 1 Class I, Division 2 Class II, Division 1 Class II, Division 2 Class III

NEMA Rating

3 3R 4 7 9

Enclosure size

4" x 6" x 4"

Cover type

Rounded

Depth

4-5/8 in

Material

Copper-free aluminum

Special features

Bolt-on mounting feet

Eaton Crouse-Hinds ECP040604 3D drawing

Crouse-Hinds series ECP Enclosures Brochure

Crouse-Hinds series ECP catalog page

ECP Explosionproof Enclosures UL certification

ECP Explosionproof Enclosures UL certification

ECP Explosionproof Enclosures UL certification

IF 1639 - ECP Explosionproof Enclosures

IF 1639 - ECP Explosionproof Enclosures

Eaton Specification Sheet - ECP040604

Eaton Specification Sheet - ECP040604

Copper-free aluminum construction delivers corrosion resistance without added weight, reducing handling risk and long-term maintenance costs while boosting reliability in harsh environments. Feature → Business Impact → Application: The rounded cover minimizes snag points and simplifies ingress protection, improving field serviceability in crowded panels or reach locations. This translates to faster service and less downtime during inspections in process plants or refineries. Feature → Business Impact → Application: 4x6x4 in enclosure size with a 4-5/8 in depth provides a compact yet robust housing that accommodates standard control components, reducing cabinet footprint on modular systems and enabling straightforward retrofits in legacy equipment. Feature → Business Impact → Application: Bolt-on mounting feet enable quick, secure mounting to equipment frames or walls, cutting installation time by eliminating custom hardware and enabling modular expansion in electrical infrastructure projects. Feature → Business Impact → Application: Copper-free aluminum combines weight advantage with corrosion resistance, lowering logistics costs and facilitating safer handling during maintenance cycles in offshore or chemical processing facilities. Feature → Business Impact → Application: NEC/CEC compliance and NEMA ratings (3, 3R, 4, 7, 9) deliver versatile protection for indoor and outdoor locations, ensuring regulatory alignment and reducing the risk of non-compliance during audits. Feature → Business Impact → Application: The enclosure supports Class I, Division 1 and 2; Class II Division 1 and 2; Class III ratings, enabling use across a wide range of hazardous-location applications in oil & gas, chemical processing, water treatment, and power distribution. All features collectively support measurable outcomes such as reduced downtime, faster retrofit cycles, and predictable total cost of ownership for industrial automation projects.

Get a Quick Quote for a Eaton Crouse-Hinds ECP040604

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton Crouse-Hinds ECP040604?

Enquire Now

FAQs

Key installation considerations include leveraging the bolt-on mounting feet for secure attachment to flat surfaces or equipment frames, ensuring a clean, dust-free area to minimize ingress, and accounting for the 4x6x4 inch footprint with its 4-5/8 inch depth. Use compatible mounting hardware and follow lockout-tagout procedures during retrofits to maintain hazardous-location compliance.

Key specs include a 4x6x4 inch enclosure size with a 4-5/8 inch depth, copper-free aluminum construction, rounded cover, 8.34 inch length, 10.34 inch height, 6.13 inch width, and a 16 lb weight. It carries NEC/CEC hazardous-location ratings and NEMA 3, 3R, 4, 7, 9 compatibility, enhancing reliability in harsh environments and simplifying regulatory compliance.

Ideal for chemical processing, oil and gas refining, water/wastewater treatment, and industrial power distribution where hazardous-location protection is required. Its copper-free aluminum construction and bolt-on feet support retrofit projects, while rounded cover and compact size aid in tight spaces common on skid-mounted systems and control panels.

It aligns with NEC/CEC standards for hazardous locations and supports Class I, Division 1 & 2; Class II, Division 1 & 2; Class III environments, along with NEMA ratings 3, 3R, 4, 7, 9. These certifications simplify audits by providing recognized compliance for hazardous-location installations and reducing the need for extensive site-specific testing.

The enclosure’s bolt-on feet enable rapid mount/removal, reducing commissioning and maintenance time. Copper-free aluminum offers corrosion resistance with lighter weight, lowering handling and replacement costs. Its broad certification coverage minimizes compliance risks and downtime during inspections, delivering a favorable total cost of ownership in long-term operation.