Eaton ECP060806 Enclosure - Hazardous Locations

Part Number: ECP060806

Manufacturer

Eaton Crouse-Hinds

Part number

ECP060806

Quick Summary

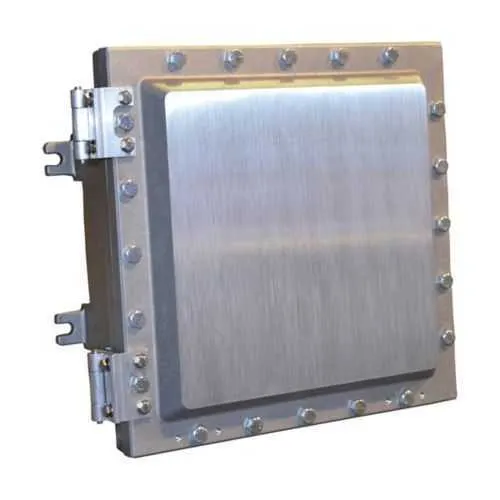

Eaton Crouse-Hinds ECP060806 enclosure protects sensitive electrical equipment in hazardous locations. Engineers and procurement teams often wrestle with rugged enclosures that meet exacting codes and withstand demanding environments. This model carries NEC/CEC compliance, UL explosion-proof certifications, and robust NEMA ratings (3, 3R, 4, 7, and 9) for versatile installation. With its copper-free aluminum body, rounded cover, and bolt-on mounting feet, the ECP060806 delivers reliable installation, faster field service, and long-term lifecycle savings for industrial plants. Its compact 6x8x6 inch size and 6-5/8 inch depth optimize cabinet footprint in crowded control rooms while maintaining rugged protection.

Product Information

Extended Description

ECP060806 Eaton Crouse-Hinds: Eaton Crouse-Hinds series ECP enclosure, Rounded cover, 6-5/8" depth, 6" x 8" x 6", Copper-free aluminum, Bolt-on mounting feet

Product Name

Eaton Crouse-Hinds series ECP enclosure

Catalog Number

ECP060806

Product Length/Depth

10.47 in

Product Height

12.47 in

Product Width

8.19 in

Product Weight

32 lb

UPC

662276310926

Area classification

Hazardous/Classified Locations

Standards type

NEC/CEC

NEC hazardous rating

Class I, Division 1 Class I, Division 2 Class II, Division 1 Class II, Division 2 Class III

NEMA Rating

3 3R 4 7 9

Enclosure size

6" x 8" x 6"

Cover type

Rounded

Depth

6-5/8 in

Material

Copper-free aluminum

Special features

Bolt-on mounting feet

Eaton Crouse-Hinds ECP060806 3D drawing

Crouse-Hinds series ECP Enclosures Brochure

Crouse-Hinds series ECP catalog page

ECP Explosionproof Enclosures UL certification

ECP Explosionproof Enclosures UL certification

ECP Explosionproof Enclosures UL certification

IF 1107 - Mounting Plate Kit

IF 1107 - Mounting Plate Kit

Eaton Specification Sheet - ECP060806

Eaton Specification Sheet - ECP060806

Copper-free aluminum construction delivers high strength with excellent corrosion resistance while keeping weight manageable. The reduced mass translates to easier transport, simpler mounting, and lower foundation and crane costs on site. In chemical processing, oil and gas, and mining environments, this material choice minimizes maintenance downtime and project risk without sacrificing enclosure integrity or IP/NEMA performance. This combination also streamlines supplier qualification by delivering repeatable, standard components. Rounded cover design improves gasket seating, reduces snag hazards, and simplifies routine maintenance. The form factor supports reliable sealing in cluttered electrical spaces, with less risk of damage from routine handling or misalignment during field service. Its rounded geometry reduces debris buildup and eases washdown cleaning in harsh environments. Compact 6x8x6 in footprint with a 6-5/8 in depth enables efficient cabinet layouts in tight control rooms and on skid-mounted equipment. The enclosure’s dimensions balance internal space for components with external fitment realities, reducing the need for extra enclosures or adapters on new builds. The footprint fits common cabinet widths, simplifying panel layout. Bolt-on mounting feet speed installation and simplify servicing by enabling field mounting without specialized fixtures. Combined with compatible mounting plates and accessories, this enclosure supports quick obsolescence planning and scalable expansion, reducing commissioning time and minimizing downtime during panel upgrades. A mounting plate compatibility guide accompanies the kit. Hazardous-location compliance and broad protection ratings reassure project teams that the enclosure meets NEC/CEC requirements, UL explosion-proof certification, and multiple NEMA standards. This reduces certification cycles, supports global deployments, and lowers risk of non-conformance in regulated industries such as oil & gas, chemical processing, and mining. These certifications support audits and vendor qualification in regulated sectors. Access to 3D CAD drawings, installation sheets, brochures, and certification reports accelerates procurement and on-site setup. With ready digital assets, engineers can validate fit, plan wiring, and align equipment with existing cabinets, reducing errors and shortening project timelines. Digital assets are available in CAD, PDF, and e-datasheet formats.

Get a Quick Quote for a Eaton Crouse-Hinds ECP060806

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton Crouse-Hinds ECP060806?

Enquire Now

FAQs

The ECP060806 features bolt-on mounting feet for quick, flexible attachment to floors or frames. For added versatility, consider using compatible IF mounting plates (IF1107/IF1639) to tailor the enclosure to your frame or cabinet system. This approach minimizes field fabrication, speeds commissioning, and improves vibration stability in demanding environments.

The enclosure is designed for hazardous/classified locations with NEC/CEC standards compliance and UL explosion-proof certification. It also aligns with multiple NEMA ratings (3, 3R, 4, 7, 9) and supports IECEx and Intertek certification documentation, enabling global deployment and streamlined approval processes for regulated facilities.

Yes, the combination of copper-free aluminum construction with rounded cover and NEMA ratings supports outdoor and washdown use in many sites. The enclosure delivers robust protection against moisture, dust, and contaminants while maintaining structural integrity and gasket performance during frequent maintenance cycles.

A full suite of resources is available: 3D CAD drawings, installation instruction sheets, product brochures, and certification reports. These assets facilitate fit verification, wiring plan development, and approvals, reducing errors and accelerating procurement and site readiness for projects across global locations.

The enclosure minimizes downtime through durable copper-free aluminum construction, reliable gasket sealing, and bolt-on feet for quick servicing. Global certifications and ready documentation support faster project approvals, lower field labor costs, and reduced rework, contributing to lower total cost of ownership over the equipment lifecycle.