Eaton Crouse-Hinds ECP101008 Enclosure - Hazardous Locations

Part Number: ECP101008

Manufacturer

Eaton Crouse-Hinds

Part number

ECP101008

Quick Summary

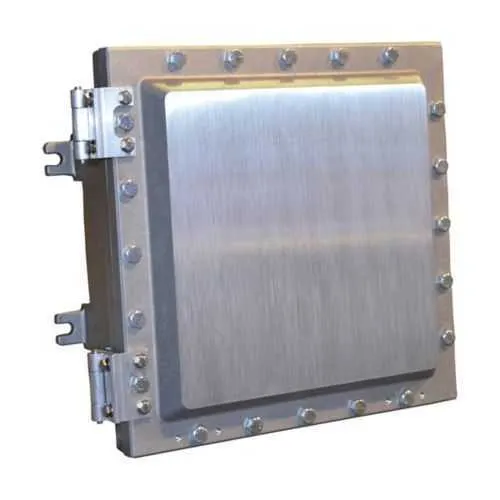

Eaton Crouse-Hinds ECP101008 enclosure protects electrical equipment in hazardous locations. In demanding plants, installers battle corrosion, downtime, and limited mounting options that slow projects. This enclosure meets NEC/CEC requirements and carries Class I, Division 1 and 2, Class II, Division 1 and 2, and Class III ratings, plus multiple NEMA protections, ensuring safe operation across varied hazardous environments. Copper-free aluminum construction and bolt-on mounting feet deliver durable protection with straightforward installation, lowering maintenance costs and enabling quick field retrofits. For engineers and buyers, the result is a robust, compliant housing that supports reliable control and easier inventory management across sites.

Product Information

Extended Description

ECP101008 Eaton Crouse-Hinds: Eaton Crouse-Hinds series ECP enclosure, Rounded cover, 8-5/8" depth, 10" x 10" x 8", Copper-free aluminum, Bolt-on mounting feet

Product Name

Eaton Crouse-Hinds series ECP enclosure

Catalog Number

ECP101008

Product Length/Depth

14.66 in

Product Height

14.66 in

Product Width

10.38 in

Product Weight

59 lb

UPC

662276310964

Area classification

Hazardous/Classified Locations

Standards type

NEC/CEC

NEC hazardous rating

Class I, Division 1 Class I, Division 2 Class II, Division 1 Class II, Division 2 Class III

NEMA Rating

3 3R 4 7 9

Enclosure size

10" x 10" x 8"

Cover type

Rounded

Depth

8-5/8 in

Material

Copper-free aluminum

Special features

Bolt-on mounting feet

Eaton Crouse-Hinds ECP101008 3D drawing

Crouse-Hinds series ECP Enclosures Brochure

Crouse-Hinds series ECP catalog page

ECP Explosionproof Enclosures UL certification

ECP Explosionproof Enclosures UL certification

ECP Explosionproof Enclosures UL certification

IF 1107 - Mounting Plate Kit

IF 1107 - Mounting Plate Kit

ECP Enclosures

ECP Enclosures

Feature: Copper-free aluminum construction delivers industry-leading corrosion resistance while keeping weight manageable. Business impact: lowers lifecycle maintenance costs and simplifies shipping and installation. Application: suitable for outdoor panels and chemical-processing environments where exposure to moisture and chemicals is routine. Feature: Rounded cover design improves gasket compression and ingress protection in dusty or wet environments. Business impact: enhances seal integrity and reduces field rework. Application: electrical control panels in milling, mining, or refinery settings where debris control matters. Feature: Dimension and capacity options with 10x10x8 inch face and 14.66 inch depth provide space for standard automation cores and wiring. Business impact: streamline panel layout and reduce need for bulky retrofits. Application: new builds and retrofits in compact enclosure requirements. Feature: Bolt-on mounting feet enable quick, secure installation with minimal hardware and field adjustments. Business impact: cuts install time and scaling costs across multiple sites. Application: panel builders and field technicians assembling control cabinets. Feature: Hazardous Locations rated with NEC/CEC compliance and NEMA protections. Business impact: ensures regulatory compliance, safety, and peace of mind. Application: chemical plants, oil refineries, mines, and other hazardous operations. Feature: Availability of CAD drawings, mounting guides, and installation sheets. Business impact: accelerates design validation and installation workflows. Application: engineering teams and procurement processes.

Get a Quick Quote for a Eaton Crouse-Hinds ECP101008

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton Crouse-Hinds ECP101008?

Enquire Now

FAQs

The ECP101008 is designed for NEC/CEC hazardous location compliance, supporting Class I and II divisions 1 and 2, as well as Class III. It uses bolt-on mounting feet for secure, field-ready installations and accepts standard automation components within its 10x10x8 inch footprint. Its copper-free aluminum body resists harsh environments, reducing corrosion-related maintenance and downtime during panel builds or retrofits.

The enclosure carries NEC/CEC standards with hazardous location ratings including Class I Division 1 and Division 2, Class II Division 1 and Division 2, and Class III. It also aligns with multiple NEMA ratings (3, 3R, 4, 7, 9) to support a broad range of industrial environments and ensures compliance for dependable operation in hazardous locations.

This enclosure excels in oil and gas, chemical processing, mining, and other industrial settings that require robust protection for electrical assemblies. Its 10x10x8 size, rounded cover, and bolt-on feet streamline control panel installations, while the copper-free aluminum construction offers long-term corrosion resistance, enabling durable panels that meet strict safety standards.

Plan for bolt-on mounting feet to simplify field mounting and reduce hardware needs. The enclosure’s copper-free aluminum body benefits from proper sealing to maintain ingress protection in dusty or moist environments. Verify component fit within the 14.66 inch depth and 10x10 inch face, and reference the included installation sheets and 3D CAD drawings for precise layout and mounting guidance.

The combination of corrosion-resistant copper-free aluminum, a rounded cover for reliable sealing, and straightforward bolt-on mounting reduces maintenance intervals and field rework. NEMA and NEC/CEC compliance minimize compliance risk, while the durable construction lowers replacement frequency. Overall, this enclosure supports safer operation, faster installations, and lower lifecycle costs in hazardous environments.