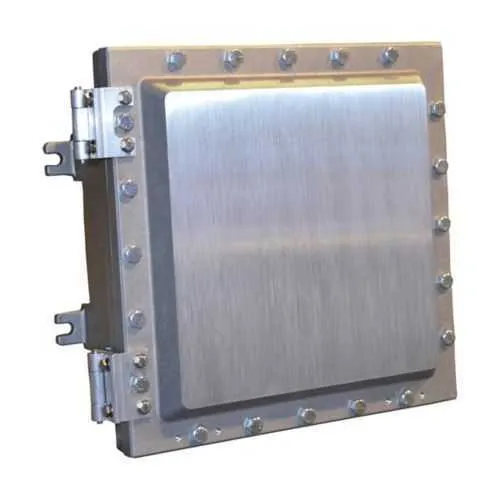

Eaton Crouse-Hinds ECP122410 Enclosure - Explosionproof

Part Number: ECP122410

Manufacturer

Eaton Crouse-Hinds

Part number

ECP122410

Quick Summary

The ECP122410 enclosure provides rugged, explosion‑proof protection for electrical equipment in hazardous locations. Upgrading legacy housings often traps engineers in long lead times, compatibility gaps, and costly recertifications. This Crouse-Hinds design carries NEC/CEC compliance, UL certification, and Intertek/IECEx documentation, with NEMA ratings 3, 3R, 4, 7, and 9 to support a broad range of hazardous environments. Coupled with copper-free aluminum and tap-in mounting feet, the solution improves installation efficiency, reduces total cost of ownership, and strengthens safety and regulatory visibility across plant-wide deployments.

Product Information

Extended Description

ECP122410 Eaton Crouse-Hinds: Eaton Crouse-Hinds series ECP enclosure, Square cover, 10-15/16" depth, 12" x 24" x 10", Copper-free aluminum, Tap-in mounting feet

Product Name

Eaton Crouse-Hinds series ECP enclosure

Catalog Number

ECP122410

Product Length/Depth

17.25 in

Product Height

29.25 in

Product Width

13.63 in

Product Weight

158 lb

UPC

662276322059

Area classification

Hazardous/Classified Locations

Standards type

NEC/CEC

NEC hazardous rating

Class I, Division 1 Class I, Division 2 Class II, Division 1 Class II, Division 2 Class III

NEMA Rating

3 3R 4 7 9

Enclosure size

12" x 24" x 10"

Cover type

Square

Depth

10-15/16 in

Material

Copper-free aluminum

Special features

Tap-in mounting feet

Eaton Crouse-Hinds ECP122410 3D drawing

Crouse-Hinds series ECP Enclosures Brochure

Crouse-Hinds series ECP catalog page

ECP Explosionproof Enclosures UL certification

ECP Explosionproof Enclosures UL certification

ECP Explosionproof Enclosures UL certification

IF 1639 - ECP Explosionproof Enclosures

IF 1639 - ECP Explosionproof Enclosures

ECP Enclosures

ECP Enclosures

Copper-free aluminum construction delivers durability without galvanic corrosion and minimizes weight for easier handling on site. This feature translates to lower maintenance costs and longer service life in chemical plants and offshore facilities. The enclosure size and dimensions align with standard configurations while the depth supports a wide range of equipment; the tap-in mounting feet speed up installation and simplify retrofits. The square cover and sealed joints provide reliable enclosure integrity, reducing moisture ingress and dust intrusion in demanding environments, supporting NEC/CEC compliance and robust NEMA protection. Tap-in mounting feet enable quick, tool-free mounting and future reconfiguration for expansions or relocations, reducing downtime and labor costs on projects. Certifications including NEC/CEC, UL, Intertek, and IECEx, plus Hazardous/Classified area ratings, reassure buyers about regulatory alignment and long-term safety. In real-world assemblies, these features translate to faster commissioning, improved traceability, and lower lifecycle costs on large-scale installations.

Get a Quick Quote for a Eaton Crouse-Hinds ECP122410

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton Crouse-Hinds ECP122410?

Enquire Now

FAQs

The ECP122410 supports quick mounting via tap-in mounting feet and is designed for use in hazardous areas. Ensure proper clearance per local codes, seal integrity on the square cover, and compatibility with your terminal blocks or switchgear. Follow UL/IECEx installation sheets to maintain the enclosure’s certification status during retrofit or expansion projects.

Yes. The enclosure is specified for NEC/CEC compliance with hazardous ratings that include Class I, Division 1 and related divisions for Class II and III environments. Always verify the exact rating against your system’s hazard classification and follow installation guidelines to retain certification during use.

The ECP122410 is manufactured from copper-free aluminum and lists enclosure size as 12 in x 24 in x 10 in in catalogs, with exterior dimensions noted as 29.25 in high, 13.63 in wide, and 17.25 in deep. The cover is square, and the unit includes tap-in mounting feet for fast mounting and service access.

The enclosure carries NEC/CEC standards, UL and IECEx/Intertek certification documentation, NEMA ratings of 3, 3R, 4, 7, and 9, and area classifications for Hazardous/Classified Locations. This mix of certifications supports compliance across global projects and helps avoid re‑certification during upgrades.

Copper-free aluminum reduces weight and corrosion risk, lowering lifecycle costs. Tap-in mounting feet speed installations and reconfigurations, cutting labor time. The combination of robust certifications and rugged construction minimizes field issues, accelerating commissioning and reducing downtime across multi-site deployments.