Eaton ECP123608 Enclosure - Hazardous Locations

Part Number: ECP123608

Manufacturer

Eaton Crouse-Hinds

Part number

ECP123608

Quick Summary

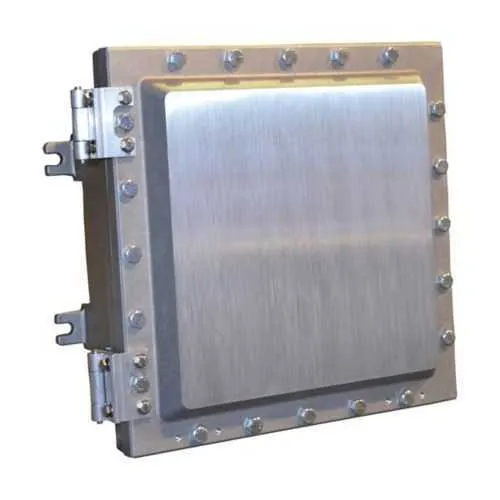

Eaton ECP123608 enclosure is a rugged, explosion-protected housing designed to guard electrical gear in hazardous locations. Engineers often wrestle with safety compliance, durability, and field install-time when choosing a dependable enclosure, and this model addresses those pain points with a proven build. This solution earns NEC/CEC compliance while delivering Class I, Division 1 and Division 2, Class II and III ratings, plus durability in demanding environments through its NEMA 3, 3R, 4, 7, and 9 compatibility. Copper-free aluminum construction and a square cover, resist corrosion, while tap-in mounting feet speed field installation and reduce mounting labor. In steady operation, it supports reliable control-panel protection against weather, dust, and impact, and aligns with accessible installation resources to accelerate project timelines.

Product Information

Extended Description

ECP123608 Eaton Crouse-Hinds: Eaton Crouse-Hinds series ECP enclosure, Square cover, 8-15/16" depth, 12" x 36" x 8", Copper-free aluminum, Tap-in mounting feet

Product Name

Eaton Crouse-Hinds series ECP enclosure

Catalog Number

ECP123608

Product Length/Depth

17 in

Product Height

41.05 in

Product Width

11.92 in

Product Weight

247 lb

UPC

662276322042

Area classification

Hazardous/Classified Locations

Standards type

NEC/CEC

NEC hazardous rating

Class I, Division 1 Class I, Division 2 Class II, Division 1 Class II, Division 2 Class III

NEMA Rating

3 3R 4 7 9

Enclosure size

12" x 36" x 8"

Cover type

Square

Depth

8-15/16 in

Material

Copper-free aluminum

Special features

Tap-in mounting feet

Eaton Crouse-Hinds ECP123608 3D drawing

Crouse-Hinds series ECP Enclosures Brochure

Crouse-Hinds series ECP catalog page

ECP Explosionproof Enclosures UL certification

ECP Explosionproof Enclosures UL certification

ECP Explosionproof Enclosures UL certification

IF 1107 - Mounting Plate Kit

IF 1107 - Mounting Plate Kit

ECP Enclosures

ECP Enclosures

Copper-free aluminum enclosure body. Business Impact: Provides superior corrosion resistance and lighter weight than steel, reducing handling time during installation and lowering lifecycle maintenance costs. Application: Ideal for chemical processing, oil and gas, and wastewater facilities where aggressive atmospheres threaten enclosure integrity and field reliability is critical. Hazardous-location ratings and compliance. Business Impact: NEC/CEC compliance with Class I, Division 1 and 2, Class II, Division 1 and 2, and Class III ratings reduces regulatory risk and speeds safe commissioning. Application: Suitable for refineries, chemical plants, mining, and other hazardous environments requiring proven protection for control gear. NEMA-rated environmental durability. Business Impact: NEMA protections 3, 3R, 4, 7, 9 provide rain, dust, impact, and chemical resistance, minimizing downtime and extending service life. Application: Outdoor or harsh indoor installations where equipment must endure weather, dust, and mechanical exposure. Dimensional efficiency and interior capacity. Business Impact: 12" x 36" x 8" enclosure size with 17" depth creates ample space for controls while keeping floor space utilization efficient. Application: Process automation panels in compact control rooms or equipment rooms that still require room for cabling and future expansion. Mounting versatility and install-time savings. Business Impact: Tap-in mounting feet and compatibility with IF 1107 mounting-plate kits speed installation and improve vibration resistance. Application: Retrofit projects or new-builds where fast, repeatable mountings reduce project risk and total installed cost.

Get a Quick Quote for a Eaton Crouse-Hinds ECP123608

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton Crouse-Hinds ECP123608?

Enquire Now

FAQs

The ECP123608 features tap-in mounting feet for quick assembly and is compatible with standard mounting accessories, including IF1107 mounting plate kits. This combination enables fast, repeatable panel mounting, reduces field labor, and improves vibration resistance in harsh environments. Reference the IF1107 instruction sheet for step-by-step guidance and ensure correct torque on fasteners during final installation.

The enclosure supports NEC/CEC compliance with Class I, Division 1 and 2, Class II, Division 1 and 2, and Class III ratings, along with NEMA protections 3, 3R, 4, 7, 9. UL certifications and IECEx/Intertek type-examination documentation are available, reinforcing safety, regulatory alignment, and field acceptance across global plants.

Yes. The combination of hazardous-location ratings (Class I/II/III) and robust corrosion resistance from copper-free aluminum makes it well suited for oil and gas, chemical processing, mining, and other harsh industrial environments where dependable protection for control gear is essential.

A comprehensive set of resources is available: 3D CAD drawings, brochures, catalog pages, and installation sheets (IF1107 and IF1639). There are also ECP specification guides and product sheets. These materials simplify engineering, enable accurate budgeting, and speed up the design-review process.

While ROI varies by project, advantages include reduced downtime from robust protection, faster commissioning due to tap-in feet and standard mounting plates, and lower maintenance costs thanks to corrosion-resistant copper-free aluminum. When combined with UL/IECEx certifications, project risk is lowered, aiding faster regulatory acceptance and schedule certainty.