Eaton Crouse-Hinds ECP182410 Enclosure - Hazardous Locations

Part Number: ECP182410

Manufacturer

Eaton Crouse-Hinds

Part number

ECP182410

Quick Summary

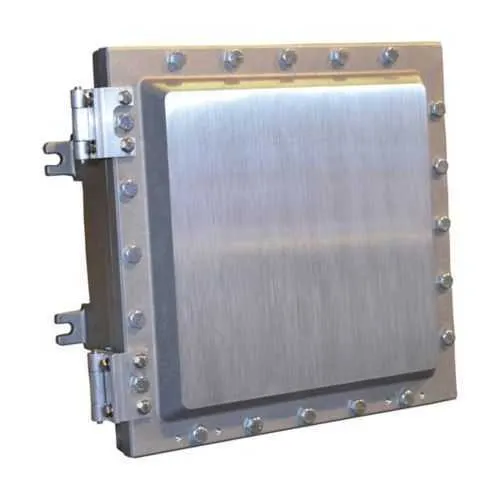

Eaton Crouse-Hinds ECP182410 enclosure is a rugged, purpose-built housing for electrical gear in hazardous locations. It shields sensitive equipment from dust, moisture, and explosive atmospheres while keeping top-mounted control components organized. The design emphasizes ease of installation and long-term reliability in demanding industrial environments. A common challenge is maintaining compliance across multiple classification schemes while minimizing downtime; this enclosure helps by offering robust certification coverage and compatible mounting options. With NEC/CEC compliance and hazardous-location ratings, it supports Class I, II, and III installations and suitable NEMA configurations for outdoor or indoor use. Businesses gain predictable maintenance cycles and safer operation when equipment resides in a certified, copper-free aluminum enclosure like this.

Product Information

Extended Description

ECP182410 Eaton Crouse-Hinds: Eaton Crouse-Hinds series ECP enclosure, Square cover, 11-7/16" depth, 18" x 24" x 10", Copper-free aluminum, Tap-in mounting feet

Product Name

Eaton Crouse-Hinds series ECP enclosure

Catalog Number

ECP182410

Product Length/Depth

23.41 in

Product Height

29.41 in

Product Width

14.31 in

Product Weight

235 lb

UPC

662276322011

Area classification

Hazardous/Classified Locations

Standards type

NEC/CEC

NEC hazardous rating

Class I, Division 1 Class I, Division 2 Class II, Division 1 Class II, Division 2 Class III

NEMA Rating

3 3R 4 7 9

Enclosure size

18" x 24" x 10"

Cover type

Square

Depth

11-7/16 in

Material

Copper-free aluminum

Special features

Tap-in mounting feet

Eaton Crouse-Hinds ECP182410 3D drawing

Crouse-Hinds series ECP Enclosures Brochure

Crouse-Hinds series ECP catalog page

Intertek EC-Type Examination Certificate

Intertek EC-Type Examination Certificate

Intertek EC-Type Examination Certificate

IF 1107 - Mounting Plate Kit

IF 1107 - Mounting Plate Kit

Eaton Specification Sheet - ECP182410

Eaton Specification Sheet - ECP182410

Copper-free aluminum construction delivers superior corrosion resistance and long-term durability, reducing maintenance cycles in harsh environments. The enclosure resists moisture, corrosive vapors, and temperature swings, helping protect sensitive control hardware and extending service life. This translates to lower replacement costs and less downtime when equipment sits in chemical plants, offshore facilities, or wash-down areas. Tap-in mounting feet simplify field installation by allowing quick, tool-free alignment and secure mounting. This feature reduces labor hours on site and minimizes misalignment risks that can cause enclosure leaks or wiring errors. The result is faster project delivery and more reliable panel assemblies in automated lines and process skids. Certifications cover the critical safety and compliance needs for hazardous environments: NEC/CEC standards and explicit Class I, Division 1 and Division 2, Class II, Division 1 and 2, and Class III ratings. Coupled with NEMA 3, 3R, 4, 7, and 9 ratings, the ECP182410 is suitable for indoor and outdoor installations exposed to dust, water, and occasional impacts, helping you qualify for regulated facilities. With a robust 18 x 24 x 10 in footprint and a 235 lb weight, the enclosure offers substantial internal space for sizeable control systems while maintaining structural rigidity. Square cover design enhances seal geometry, and copper-free aluminum keeps the unit light for its size relative to steel alternatives. Heavy-duty mounting feet and a compatible footprint support reliable integration into existing switchgear and MCCs. Compatibility is enhanced by readily available installation resources, including 3D CAD drawings, brochures, and spec sheets. The IF 1107 mounting plate kit and related instruction sheets simplify upgrades and retrofit projects, accelerating time-to-commission and ensuring correct fitment with standard DIN rails and mounted components.

Get a Quick Quote for a Eaton Crouse-Hinds ECP182410

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton Crouse-Hinds ECP182410?

Enquire Now

FAQs

For hazardous locations, plan mounting on a stable surface using the built-in tap-in feet and compatible mounting plates. Use the IF 1107 mounting plate kit for streamlined retrofits, verify clearances for cables, and follow NEC/CEC wiring methods. The enclosure’s size and weight (18x24x10 in footprint, 235 lb) influence lifting equipment needs and assembly sequencing to avoid field injuries.

Yes, the ECP182410 carries NEC/CEC compliance and is rated for Class I Division 1 and 2, Class II Division 1 and 2, and Class III environments. It also supports multiple NEMA configurations, including 3, 3R, 4, 7, and 9, making it suitable for a wide range of hazardous-location installations in oil & gas, chemical processing, and heavy manufacturing.

The enclosure features tap-in mounting feet for fast, precise alignment and a square cover for reliable sealing. It supports mounting plates and standard DIN rail components, with downloadable 3D CAD drawings to aid clash detection and footprint planning. The 18x24x10 in size accommodates sizeable control gear while maintaining a sturdy, secure installation.

Constructed from copper-free aluminum, the enclosure offers excellent corrosion resistance and temperature resilience. With NEMA ratings 3, 3R, 4, 7, and 9 and hazardous-location classifications, it provides robust ingress protection and safety for equipment in dusty, wet, or potentially explosive environments, reducing maintenance costs and downtime.

Eaton provides comprehensive documentation including 3D CAD drawings, brochures, and specification sheets. Access installation instructions such as IF 1107 and IF 1639, plus the ECP182410 spec sheet, to guide mounting, wiring, and retrofits. These resources streamline planning, ensure correct fitment, and support compliant installations.