Eaton Crouse-Hinds ECP243008 Enclosure - Hazardous/Classified Locations

Part Number: ECP243008

Manufacturer

Eaton Crouse-Hinds

Part number

ECP243008

Quick Summary

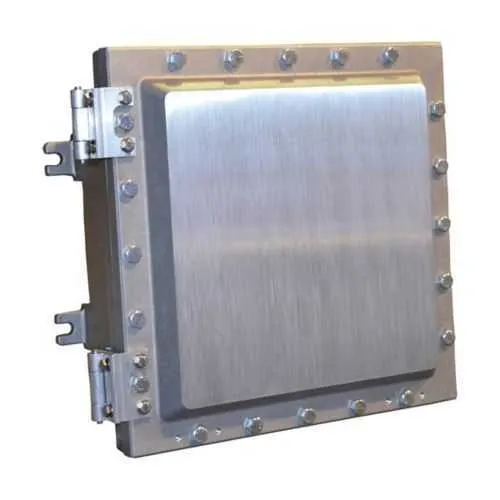

Eaton Crouse-Hinds ECP243008 enclosure provides rugged protection for electrical equipment in hazardous locations. Facility teams often struggle with safe, code-compliant installations in space-constrained, harsh industrial environments. The enclosure meets NEC/CEC requirements and offers hazardous-location ratings including Class I Division 1 and 2, Class II Division 1 and 2, and Class III, while providing versatile NEMA types 3, 3R, 4, 7, 9—supporting a wide range of process and power applications. Built with copper-free aluminum and a square cover, it resists corrosion and simplifies field maintenance. Tap-in mounting feet speed installation and reduce labor, while compatibility with the broader ECP line supports scalable, long-term reliability for safety-critical systems.

Product Information

Extended Description

ECP243008 Eaton Crouse-Hinds: Eaton Crouse-Hinds series ECP enclosure, Square cover, 9-1/4" depth, 24" x 30" x 8", Copper-free aluminum, Tap-in mounting feet

Product Name

Eaton Crouse-Hinds series ECP enclosure

Catalog Number

ECP243008

Product Length/Depth

30 in

Product Height

36 in

Product Width

13.13 in

Product Weight

428 lb

UPC

662276320215

Area classification

Hazardous/Classified Locations

Standards type

NEC/CEC

NEC hazardous rating

Class I, Division 1 Class I, Division 2 Class II, Division 1 Class II, Division 2 Class III

NEMA Rating

3 3R 4 7 9

Enclosure size

24" x 30" x 8"

Cover type

Square

Depth

9-1/4 in

Material

Copper-free aluminum

Special features

Tap-in mounting feet

Eaton Crouse-Hinds ECP243008 3D drawing

Crouse-Hinds series ECP Enclosures Brochure

Crouse-Hinds series ECP catalog page

IECEx Certificate of Conformity

IECEx Certificate of Conformity

IECEx Certificate of Conformity

IF 1639 - ECP Explosionproof Enclosures

IF 1639 - ECP Explosionproof Enclosures

ECP Enclosures

ECP Enclosures

Copper-free aluminum construction delivers strong corrosion resistance in chemical, offshore, and outdoor environments, extending service life and reducing maintenance costs. This translates to fewer field replacements and lower total cost of ownership for mission-critical equipment. Hazardous location compatibility and NEC/CEC alignment ensure regulatory compliance from installation through operation. The enclosure supports Class I, II, and III ratings and NEMA types 3, 3R, 4, 7, 9, enabling safe housing of drives, control panels, and instrumentation in harsh zones. The 24 x 30 x 8 in enclosure with a square cover combines ample internal volume with a compact exterior footprint, simplifying control-panel layouts. Tap-in mounting feet enable rapid, passive alignment and secure attachment, cutting install time in typical assemblies. Compatibility with the broader ECP accessory ecosystem and access to 3D CAD drawings, brochures, and installation sheets reduces engineering risk and speeds commissioning. For process industries, this enclosure reduces downtime, improves safety, and ensures compliance with hazardous-location standards, while its copper-free aluminum helps mitigate grounding and corrosion concerns.

Get a Quick Quote for a Eaton Crouse-Hinds ECP243008

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton Crouse-Hinds ECP243008?

Enquire Now

FAQs

When installing the ECP243008 in hazardous areas, ensure conformance with Class I, II, and III requirements and follow NEC/CEC guidelines. Use the tap-in mounting feet to speed alignment and secure mounting, verify proper enclosure grounding, and plan for the 24 x 30 x 8 inch internal space to accommodate panels, drives, or instrumentation while maintaining safe clearances around ventilation and cable entries.

The ECP243008 carries NEC/CEC compliance with hazardous-location ratings including Class I Division 1 and 2, Class II Division 1 and 2, and Class III, along with NEMA ratings 3, 3R, 4, 7, and 9. These certifications support safe operation in hazardous environments and align with international expectations for explosion-protected enclosures.

Yes. The enclosure is designed for hazardous/classified locations and is compatible with oil and gas and chemical processing applications. Its copper-free aluminum construction provides corrosion resistance, while the explosion-proof design and appropriate NEMA ratings help protect equipment in demanding process areas.

A comprehensive set of resources is available, including 3D CAD drawings, brochures, catalogs, installation sheets, and data sheets. These materials support accurate design integration, faster procurement, and smoother commissioning of ECP243008-based installations.

The copper-free aluminum construction reduces corrosion-related maintenance and extends service life, lowering lifecycle costs. Quick-install features like tap-in mounting feet shorten commissioning time, reducing labor costs. Regulatory compliance with NEC/CEC and robust NEMA ratings minimize risk of failures and unplanned downtime, delivering a favorable return on investment for hazardous-location projects.