Eaton Crouse-Hinds ECP243610 Enclosure - Hazardous Locations

Part Number: ECP243610

Manufacturer

Eaton Crouse-Hinds

Part number

ECP243610

Quick Summary

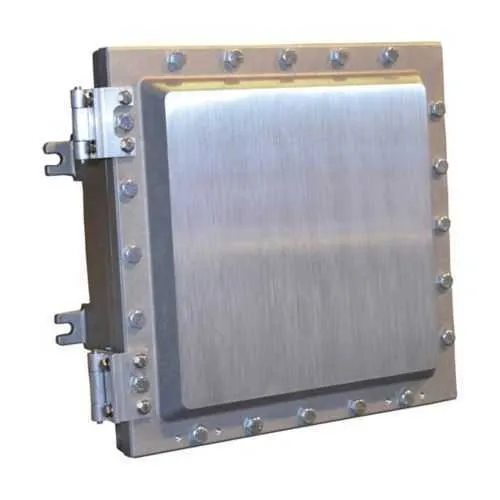

Eaton Crouse-Hinds ECP243610 enclosure protects equipment in hazardous locations across industrial facilities. Many projects stall when installers face corrosion risk, difficult mounting, or inadequate protection in harsh environments. This model carries UL explosionproof certification, Intertek/IECEx conformity, and NEC/CEC compliance, with robust NEMA ratings for Class I, Division 1/2 and Class II, Division 1/2 locations. The copper-free aluminum construction and square cover offer dependable service life, while tap-in mounting feet simplify installation and field adjustments. Suitable for chemical plants, refineries, and offshore platforms requiring rugged protection, the ECP243610 helps reduce maintenance overhead and accelerates safe, compliant installations across demanding applications.

Product Information

Extended Description

ECP243610 Eaton Crouse-Hinds: Eaton Crouse-Hinds series ECP enclosure, Square cover, 11-1/4" depth, 24" x 36" x 10", Copper-free aluminum, Tap-in mounting feet

Product Name

Eaton Crouse-Hinds series ECP enclosure

Catalog Number

ECP243610

Product Length/Depth

29.86 in

Product Height

41.86 in

Product Width

15.13 in

Product Weight

533 lb

UPC

662276321618

Area classification

Hazardous/Classified Locations

Standards type

NEC/CEC

NEC hazardous rating

Class I, Division 1 Class I, Division 2 Class II, Division 1 Class II, Division 2 Class III

NEMA Rating

3 3R 4 7 9

Enclosure size

24" x 36" x 10"

Cover type

Square

Depth

11-1/4 in

Material

Copper-free aluminum

Special features

Tap-in mounting feet

Eaton Crouse-Hinds ECP243610 3D drawing

Crouse-Hinds series ECP Enclosures Brochure

Crouse-Hinds series ECP catalog page

ECP Explosionproof Enclosures UL certification

ECP Explosionproof Enclosures UL certification

ECP Explosionproof Enclosures UL certification

IF 1639 - ECP Explosionproof Enclosures

IF 1639 - ECP Explosionproof Enclosures

Eaton Specification Sheet - ECP243610

Eaton Specification Sheet - ECP243610

Copper-free aluminum construction provides excellent corrosion resistance in aggressive environments, reducing maintenance costs and extending service life for continuous operation in chemical processing and petrochemical plants. This translates to fewer shutdowns and lower total cost of ownership, especially where enclosure integrity is critical for safety and compliance. The 24" x 36" x 10" enclosure with a square cover delivers ample internal space for controllers, power distribution, and wiring, enabling engineers to accommodate evolving control architectures while maintaining neat, code-compliant layouts. Tap-in mounting feet streamline on-site installation, minimizing field labor and misalignment risks, which shortens project timelines in offshore and plants with tight installation windows. With Class I, Division 1/2 and Class II, Division 1/2 readiness and NEC/CEC compliance, this unit supports reliable operation in hazardous locations and simplifies procurement for compliant systems. The 533 lb rugged enclosure carries NEMA ratings 3, 3R, 4, 7, and 9, offering proven protection against dust, moisture, corrosion, and harsh impact in outdoor, industrial, and explosive environments. Documentation and CAD resources, plus compatibility with Crouse-Hinds installation instructions, further reduce design risk and ensure smooth integration with existing automation hardware and field-babrication practices.

Get a Quick Quote for a Eaton Crouse-Hinds ECP243610

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton Crouse-Hinds ECP243610?

Enquire Now

FAQs

For hazardous locations, plan mounting with the included tap-in feet to ensure precise alignment and fast field assembly. Confirm space for the 24" x 36" x 10" enclosure and ample cable entry, while adhering to NEC/CEC requirements and the Class I/Div 1 and Class II/Div 1 classifications. Use the copper-free aluminum body to resist corrosion in chemical or offshore environments and reference the supplied installation instructions for proper grounding and sealing procedures.

Key specs include 24" x 36" x 10" enclosure size with a 11-1/4 in depth, constructed from copper-free aluminum, and a square cover. It weighs 533 lb and carries NEMA ratings 3, 3R, 4, 7, and 9, with NEC/CEC compliance and Class I, II, III hazardous location ratings. The unit supports tap-in mounting feet for quick installation and aligns with 3D CAD drawings and official spec sheets for accurate design integration.

Yes. The enclosure is designed for hazardous/classified locations with protection for Class I and II environments and Class III considerations. Its copper-free aluminum construction resists corrosion in chemical and offshore settings, while NEMA ratings 3/3R/4/7/9 provide robust weather and impact protection. For offshore or chemical processing applications, verify compatibility with local codes, then integrate with certified components and installation sheets to maintain compliance and safe operation.

The ECP243610 carries NEC/CEC compliance and hazardous location ratings, including Class I, Division 1/2, Class II, Division 1/2, and Class III. It aligns with NEMA 3, 3R, 4, 7, and 9 standards for demanding environments. Certification documentation is available via UL, Intertek/IECEx, and IEC-based certificates, and installation and spec sheets are provided to support regulatory review and audit readiness.

The copper-free aluminum construction minimizes corrosion-related maintenance, extending service life in harsh environments and reducing replacement cycles. Ease of installation with tap-in feet lowers labor costs and speeds time-to-operation. Together with comprehensive documentation and certifications, the ECP243610 supports lower total cost of ownership, improved uptime, and faster project deployment in hazardous-location applications.