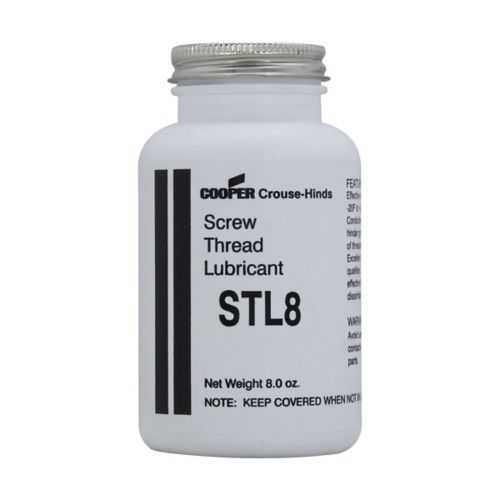

Eaton Crouse-Hinds STL8 Thread Lubricant - Hazardous/Classified Locations

Part Number: STL8

Quick Summary

STL8 thread lubricant from Eaton Crouse-Hinds is designed to lubricate and protect threaded connections in electrical conduit installations. This helps reduce galling and seizing during assembly, especially in tight, retrofit, or high-downtime environments where delays cost productivity. The formulation aligns with NEC/CEC standards and is suitable for Hazardous/Classified Locations, ensuring safer, code-compliant installations. For engineers and procurement teams, STL8 delivers predictable performance in demanding facilities, while the 8 oz can supports convenient stocking and handling. By combining dependable lubrication with code compliance, STL8 helps maintenance schedules stay on track and operational costs stay in check, particularly in industrial plants and transmission/distribution settings.

Product Information

Extended Description

STL8 Eaton Crouse-Hinds: Eaton Crouse-Hinds series STL thread lubricant, Effective and stable from -20°F to +300°F, 8 oz can

Product Name

Eaton Crouse-Hinds series STL thread lubricant

Catalog Number

STL8

UPC

782274614250

Product Length/Depth

2.5 in

Product Height

4.5 in

Product Width

2.5 in

Product Weight

0.59 lb

Area classification

Hazardous/Classified Locations

Standards type

NEC/CEC

Type

8 oz can

Special features

Effective and stable from -20°F to +300°F

Crouse-Hinds series STL and HTL Thread Lubricants catalog page

IF 1795 - STL8 Thread Lubricant Safety Data Sheet

Eaton Specification Sheet - STL8

STL8 comes in an 8 oz can, engineered to stay effective and stable from -20°F to +300°F, ensuring threads stay lubricated from cold ambient conditions to hot indoor environments. The result is reduced installation friction, minimized galling, and faster, more reliable connections across conduit systems in demanding facilities. This performance translates to lower maintenance downtime and steadier torque control during assembly, especially in retrofits or high-volume wiring projects. The lubricant is NEC/CEC compliant and appropriate for Hazardous/Classified Locations, delivering regulatory peace of mind and safer installations in chemical plants, offshore facilities, and manufacturing floors. Documentation and safety data are readily available, supporting safer work practices and faster onboarding for field technicians. Packaging efficiency with an 8 oz can helps field teams stock and deploy consistently, reducing waste and inventory cost while supporting scalable projects. From a reliability perspective, STL8 enhances thread life and resists wash-off, contributing to longer service intervals and lower rework costs in high-demand environments.

Get a Quick Quote for a Eaton Crouse-Hinds STL8

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton Crouse-Hinds STL8?

Enquire Now

FAQs

STL8 is designed for conventional conduit thread interfaces and should be applied to clean, dry threads before assembly. For best results, apply a thin, even coat along the mating threads, assemble promptly to minimize slip, and re-torque per your standard practices. The 8 oz can format supports field service where easy access and controlled application are essential, contributing to faster builds with less thread galling and seizing.

STL8 remains effective from -20°F to +300°F, ensuring lubrication and protection across cold outdoor environments and hot indoor conditions. This stability reduces torque fluctuations and thread wear, enabling reliable connections in outdoor enclosures, weatherproof fittings, and control cabinets, while limiting maintenance interruptions due to seized or damaged threads.

Yes, STL8 is suitable for Hazardous/Classified Locations and is aligned with NEC/CEC standards. This helps you meet regulatory requirements during code compliance audits and supports safe, reliable installations in environments with restricted or flammable atmospheres, such as chemical processing, oil and gas, and certain manufacturing facilities.

You can access the STL8 Safety Data Sheet (IF 1795) and the Eaton STL8 specification sheet from Eaton’s official resources. These documents provide handling, safety, and technical installation guidance to support safe procurement, training, and field operations.

Using STL8 reduces thread galling and seizing, speeds up assembly, and lowers rework and downtime. The reliable torque control and long-lasting lubrication translate into faster project completion, fewer maintenance calls, and overall cost savings in large-scale conduit installations and retrofits.