Eaton 6A-18-30HB36 Horizontal Bend - 30°, CE/UL Classified

Part Number: 6A-18-30HB36

Quick Summary

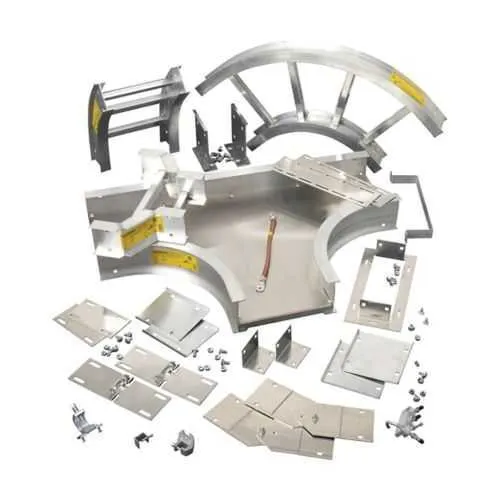

Eaton 6A-18-30HB36 is a horizontal bend for cable tray routing in industrial facilities. Engineers often struggle with space constraints and misalignment when negotiating turns in crowded equipment areas. This part carries CE, CSA, and UL Classified certifications to support compliance and safety in demanding environments. When paired with Eaton B-Line fittings and aluminum cable tray systems, it enables faster, more reliable installations and helps reduce lifecycle costs through fewer fittings and smoother routing. The combination of proven geometry and certified performance supports safer, more efficient electrical and mechanical installations across manufacturing, data centers, and process facilities.

Product Information

Extended Description

6A-18-30HB36 Eaton: Eaton B-Line series horizontal bend, 6" H x 28.0625" W x 18" L, Aluminum, 36" radius, 30° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-18-30HB36

UPC

781011208653

Product Length/Depth

28.0625 in

Product Height

6 in

Product Width

18 in

Product Weight

7.9 lb

Certifications

CE CSA UL Classified

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

30°

Radius

36 in

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-18-30HB36

Feature: Precise bend geometry with a 30° angle and a 36 in radius, plus a 28.0625 in length. Business Impact: Predictable cable routing reduces rework and lowers assembly time on site. Application: Ideal for long-span runs in manufacturing floors and data centers where space constraints demand controlled curvature. Feature: Aluminum construction with a 7.9 lb weight. Business Impact: Lighter, easier handling lowers labor costs and simplifies on-site maneuvering without sacrificing strength. Application: Indoor facilities with corrosion considerations and frequent equipment maintenance. Feature: CE, CSA, UL Classified certifications. Business Impact: Eases regulatory audits and ensures compatibility with code requirements. Application: Projects subject to building and electrical standards in North America and Europe. Feature: Compatibility with Eaton B-Line Series 2-5 fittings and aluminum/steel tray sections. Business Impact: Speeds up procurement and reduces inventory variety by using a common family of components. Application: Data centers, plants, and facilities that deploy modular cable management strategies. Feature: 30° bend with a 36 in radius minimizes fittings count. Business Impact: Fewer joints mean quicker installation and lower potential points of failure. Application: Complex routing around machinery and across aisles in industrial environments.

Get a Quick Quote for a Eaton 6A-18-30HB36

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-18-30HB36?

Enquire Now

FAQs

The 6A-18-30HB36 is designed as part of Eaton’s B-Line series and aligns with Series 2-5 horizontal bends. It matches the 28.0625 in length, 6 in height, and 18 in width of standard aluminum cable tray components, enabling straightforward integration with existing trays and fittings.

Key specs include aluminum construction, 30° angle, 36 in radius, 28.0625 in length, 6 in height, 18 in width, and a weight of 7.9 lb. Certifications are CE, CSA, and UL Classified, with UPC 781011208653.

Yes. The 30° bend with a 36 in radius provides smooth cable routing around equipment and along aisles, reducing the number of fittings required. Its aluminum construction and certifications support safe, compliant installations in data centers and manufacturing environments.

CE, CSA, and UL Classified certifications are listed for this bend, signaling compliance with Europe and North American safety standards and facilitating code audits and procurement approvals.

Leverage the standardized Series 2-5 fittings for quick assembly, reference the Eaton Cable Tray manuals and spec sheets, and plan routes to minimize turns. The bend’s weight and dimensions support easier lifting and placement, reducing on-site labor and downtime during installation.