Eaton 6A-18-30HB48 Horizontal Bend - UL Classified

Part Number: 6A-18-30HB48

Quick Summary

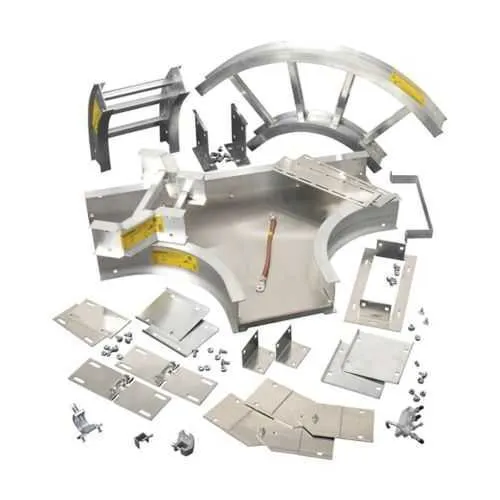

Eaton 6A-18-30HB48 is a horizontal bend used in cable tray systems to route electrical wiring efficiently in industrial facilities. Installers often battle misalignment, incompatible fittings, and time-consuming field adaptations that extend project timelines. Built to UL Classified, CSA, and CE standards, this aluminum bend offers robust protection and traceable compliance across global projects. Designed for B-Line series installations, it delivers installation-ready performance, lightweight handling, and reliable routing for scalable cable management.

Product Information

Extended Description

6A-18-30HB48 Eaton: Eaton B-Line series horizontal bend, 6" H x 34.1250" W x 18" L, Aluminum, 48" radius, 30° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-18-30HB48

UPC

781011208592

Product Length/Depth

34.125 in

Product Height

6 in

Product Width

18 in

Product Weight

9.252 lb

Certifications

UL Classified CSA CE

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

30°

Radius

48 in

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-18-30HB48

Aluminum construction provides corrosion resistance and a lightweight handling profile, reducing weight-related strain during installation while maintaining structural integrity for long-term service. The 48 in radius enables smooth, low-stress turns that minimize conductor fatigue and support high-density cable runs in data centers and manufacturing floors. A 30° bend precisely offsets runs to match standard floor plans, improving fitment in tight spaces and accelerating project timelines. With a 34.125 in length, 6 in height, and 18 in width, the unit integrates cleanly with Series 2-5 horizontal bends and the Eaton B-Line system, ensuring compatibility and reducing custom fabrication. Certifications UL Classified, CSA, and CE provide regulatory confidence for global deployments and customer audits. The 9.252 lb weight balance simplifies handling on ladders and racks, boosting on-site productivity while reducing labor costs. This bend is designed for installation efficiency with KwikSplice and Redi-Rail system compatibility, streamlining field assembly and ongoing maintenance for cable tray networks.

Get a Quick Quote for a Eaton 6A-18-30HB48

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-18-30HB48?

Enquire Now

FAQs

The 6A-18-30HB48 is compatible with Eaton B-Line Series 2-5 horizontal bends and standard aluminum cable tray components. It matches a 30° offset and 48 in radius, with dimensions designed to fit typical 34.125 in length, 6 in height, and 18 in width installations. Always verify catalog number and confirm UL Classified CSA CE compliance before field assembly.

Key specs include material aluminum, radius 48 in, angle 30°, height 6 in, width 18 in, length 34.125 in, weight 9.252 lb, catalog number 6A-18-30HB48, and UPC 781011208592. Certifications include UL Classified, CSA, and CE. This ensures reliable performance and regulatory compliance across industrial cable management applications.

Yes. The 48 in radius and 30° bend are designed to minimize bend-induced stress on dense cabling in data centers and manufacturing floors. Aluminum construction reduces weight for quick installations, while UL Classified CSA CE certifications ensure compliance with industry standards. Its compatibility with Eaton’s B-Line system supports scalable, efficient cable management across facilities.

The bend carries UL Classified, CSA, and CE certifications. These endorsements verify safety, performance, and regulatory compliance for electrical and data cabling installations worldwide. For procurement and audits, these certifications help demonstrate product conformity, enable standardized installation practices, and reduce risk in regulated environments.

The 6A-18-30HB48 supports Eaton’s KwikSplice Cable Tray System and Redi-Rail series fittings, enabling faster field assembly with fewer misfits. Its precise 30° angle and 48 in radius simplify routing around obstacles, while the aluminum construction lowers weight and handling effort. Together, these features shorten commissioning times and improve overall project ROI.