Eaton 6A-18-45HB12 B-Line Horizontal Bend - Aluminum CE

Part Number: 6A-18-45HB12

Quick Summary

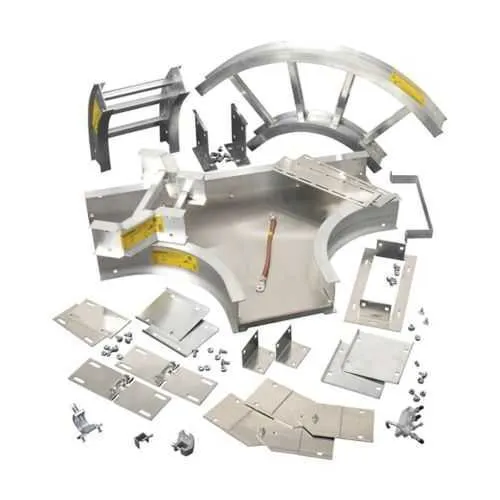

The Eaton B-Line horizontal bend redirects cable tray runs around corners in electrical enclosures and data centers. Engineers often face misaligned trays, complex fittings, and slow installations that disrupt project timelines. CSA UL CE certifications ensure compliance for global installations and reduce reprioritization risk. Built from aluminum, it combines light handling with rugged durability for installation in busy plant environments. A 12 in radius and 45° angle support smooth transitions in tight spaces, enhancing traceability and reducing slack. Leveraging these specifications, you gain faster commissioning, consistent cable routing, and lower total installation costs.

Product Information

Extended Description

6A-18-45HB12 Eaton: Eaton B-Line series horizontal bend, 6" H x 20" W x 18" L, Aluminum, 12" radius, 45° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-18-45HB12

UPC

781011208561

Product Length/Depth

20 in

Product Height

6 in

Product Width

18 in

Product Weight

7.2 lb

Certifications

CSA UL Classified CE

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

45°

Radius

12 in

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-18-45HB12

Feature: Aluminum construction. Business Impact: The material delivers corrosion resistance and a favorable strength-to-weight ratio, which translates into easier transport, fewer handling injuries, and lower installation fatigue for crews working in tight cable runs. Application: Ideal for indoor industrial cable-tray systems, including commercial buildings and manufacturing facilities where long-lasting performance and quick field adjustments matter most. Feature: Dimensions and geometry. Business Impact: The 20 in length, 6 in height, and 18 in width with a 12 in radius and 45° bend provide a predictable footprint that simplifies layout planning, reduces guesswork, and minimizes clearance conflicts around equipment. Application: Use in straight sections and corners of Eaton B-Line trays to maintain consistent pathways from panel to mezzanine. Feature: Weight 7.2 lb. Business Impact: Lightweight components reduce handling time and enable easier one-person installs without sacrificing rigidity. Application: Particularly beneficial for installations in tight spaces or above cabinets. Feature: Type and Certifications. Business Impact: Series 2-5 horizontal bend compatibility plus CSA UL CE certifications support regulatory compliance across regions, reducing rework and audit findings. Application: Deploy in new builds and retrofits across manufacturing floors and data centers. Feature: Documentation access. Business Impact: Quick-reference catalogs and installation guides minimize downtime and avoid wrong fittings. Application: Use the KwikSplice and cable-tray manuals during on-site setup and future upgrades.

Get a Quick Quote for a Eaton 6A-18-45HB12

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-18-45HB12?

Enquire Now

FAQs

Yes. The 6A-18-45HB12 is designed for Eaton B-Line series cable tray systems, matching the Series 2-5 horizontal bend type. It aligns with standard aluminum tray widths and mounting patterns, and Eaton provides catalogs and spec sheets to confirm fitment. When installing, verify catalog numbers and mounting hardware to ensure seamless integration.

The bend measures 20 in long, 6 in high, and 18 in wide, with a 12 in radius and a 45° bend. This creates a controlled, gradual turn that preserves cable integrity, reduces bending strain, and minimizes interference with adjacent components. Use these specs to plan routes through racks, corners, and equipment enclosures.

Yes. The aluminum construction provides corrosion resistance and a robust profile appropriate for data centers and industrial floors. Certifications CSA UL CE ensure compliance with global codes, while the 12 in radius and 45° angle support efficient cooling and airflow around densely packed trays in critical facilities.

The 6A-18-45HB12 carries CSA, UL Classified, and CE certifications. These markings indicate conformity to North American and international safety standards, helping you meet building and electrical codes, simplify audits, and reduce project risk when deploying cable-tray infrastructure across multiple sites.

With a 7.2 lb weight and straightforward mounting compatible with Eaton B-Line fittings, installation tends to be faster and requires fewer personnel. Aluminum construction resists corrosion, reducing maintenance needs. Documentation such as catalogs and a dedicated specification sheet supports ongoing maintenance and future upgrades without extensive rework.