Eaton 6A-18-45HB24 Horizontal Bend - CE UL CSA

Part Number: 6A-18-45HB24

Quick Summary

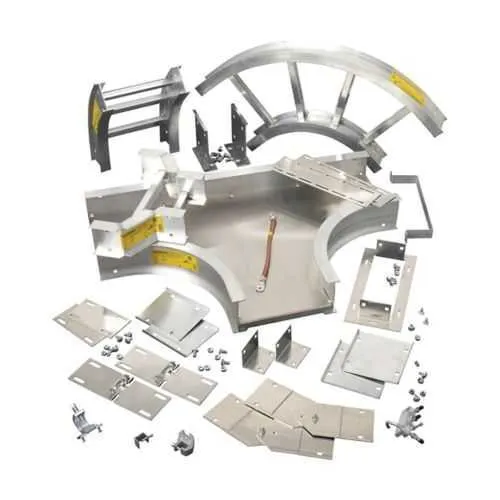

Eaton B-Line series horizontal bend enables precise 45° cable tray routing for vertical-to-horizontal transitions in electrical enclosures and process plants. The primary challenge engineers face is aligning trays in tight spaces without introducing stress on cables or excessive installation time. This part carries CE, UL Classified, and CSA certifications, providing confidence in global compliance and safety. Made from aluminum for lightweight strength, it supports a 24 in radius and a 28.5 in length with a compact 6 in by 18 in footprint. Integrating this bend reduces field labor, improves airflow, and preserves cable integrity, while ensuring compatibility with Eaton B-Line and Series 2-5 cable management systems.

Product Information

Extended Description

6A-18-45HB24 Eaton: Eaton B-Line series horizontal bend, 6" H x 28.5" W x 18" L, Aluminum, 24" radius, 45° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-18-45HB24

UPC

781011208615

Product Length/Depth

28.5 in

Product Height

6 in

Product Width

18 in

Product Weight

10 lb

Certifications

CE UL Classified CSA

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

45°

Radius

24 in

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-18-45HB24

Feature → Business Impact → Application: Aluminum construction delivers corrosion resistance and reduced weight, minimizing handling risk during installation and enabling longer service life in harsh environments; this translates to lower maintenance costs and a faster deployment across data centers and manufacturing floors. Feature → Business Impact → Application: 24 in radius and 45° angle provide consistent, code-compliant routing that reduces cable stress and bend-induced wear, improving reliability in power and control panel enclosures. Feature → Business Impact → Application: CE UL CSA certifications simplify regulatory approvals for multinational projects, accelerating procurement cycles and audit readiness for pharmaceutical plants, food & beverage facilities, and automation lines. Feature → Business Impact → Application: 28.5 in length with a 6 in x 18 in footprint fits tight enclosures and modular trench layouts, enabling scalable layouts in large-scale switchgear rooms and distribution centers. Feature → Business Impact → Application: 10 lb weight enhances on-site handling without requiring heavy equipment, streamlining install time and decreasing labor costs while maintaining robust mechanical strength. Feature → Business Impact → Application: Compatibility with KwikSplice and standard Eaton cable tray components ensures seamless integration in existing B-Line installations, reducing part skew and inventory complexity in facilities management. Feature → Business Impact → Application: The aluminum Series 2-5 horizontal bend supports improved airflow and cable organization, addressing common objections about heat buildup and misrouting in crowded cable trays.

Get a Quick Quote for a Eaton 6A-18-45HB24

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-18-45HB24?

Enquire Now

FAQs

To install the 6A-18-45HB24, align the bend with the existing Eaton B-Line series tray sections, secure using standard fasteners or KwikSplice-compatible fittings, and verify the 24 in radius and 45° angle before tightening. This minimizes misalignment and ensures a consistent, code-compliant bend. Refer to the Eaton installation instructions for step-by-step guidance and torque specifications.

Key specifications include aluminum construction, 28.5 in product length, 6 in height, 18 in width, a 24 in radius, and a 45° bend angle. The unit weighs 10 lb and carries CE, UL Classified, and CSA certifications, making it suitable for global installations and demanding industrial environments.

Yes. The 6A-18-45HB24 is designed as a B-Line horizontal bend for Series 2-5 aluminum cable trays, ensuring seamless integration with other Eaton components and maintaining consistent tray geometry for reliable cable routing and support.

The bend is CE, UL Classified, and CSA certified. These certifications verify compliance with European, North American, and CSA safety and performance standards, streamlining approvals for regulated industries and enabling broader project applicability in multinational facilities.

The aluminum construction reduces weight and simplifies handling, cutting installation time and labor costs. The 24 in radius and 45° angle deliver predictable routing that minimizes cable wear, enabling longer service life and lower maintenance. Certified compatibility with Eaton systems supports faster procurement, reducing project lead times and improving overall ROI.