Eaton 6A-18-45HB36 Horizontal Bend - 36 in Radius

Part Number: 6A-18-45HB36

Quick Summary

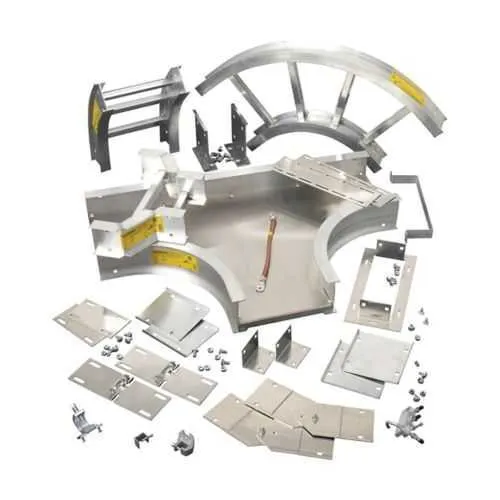

The Eaton B-Line horizontal bend is a rugged aluminum elbow for routing cable trays in industrial enclosures. Designers often confront tight spaces, fitment tolerances, and long lead times for custom bends, which can slow project timelines. This model carries CSA, UL Classified, and CE certifications to support compliant installations across North America and Europe. With a 36 in radius aluminum construction, it delivers lightweight durability, reduces installation time, and lowers total system cost for wire management projects. Its compatibility with standard KwikSplice and channel systems simplifies field retrofits and future changes. This combination of certifications, lightweight aluminum, and proven geometry supports safer, faster, and cost-effective installations.

Product Information

Extended Description

6A-18-45HB36 Eaton: Eaton B-Line series horizontal bend, 6" H x 37" W x 18" L, Aluminum, 36" radius, 45° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-18-45HB36

UPC

781011208660

Product Length/Depth

37 in

Product Height

6 in

Product Width

18 in

Product Weight

12.4 lb

Certifications

CSA UL Classified CE

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

45°

Radius

36 in

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-18-45HB36

Feature: Aluminum construction and 45° angle provide a robust, lightweight bend that reduces handling strain and corrosion risk. Benefit: Improves site safety and worker efficiency while extending service life in demanding environments. Application: Ideal for general cable tray routing in manufacturing floors and electrical rooms. Feature: 36 in radius delivers smooth transitions and minimizes the number of fittings required. Benefit: Faster installation, fewer joints, and lower labor costs on large-scale cable tray runs. Application: Data centers and process facilities with dense cable layouts benefit from fewer components and reduced heat buildup. Feature: CSA UL CE certifications ensure regulatory compliance across regions. Benefit: Streamlined procurement and safer installations that meet international standards. Application: Global projects requiring cross-border approvals. Feature: Series 2-5 horizontal bend designation and aluminum construction optimize compatibility with Eaton B-Line components. Benefit: Seamless integration with existing B-Line infrastructure and easy field retrofit. Application: New builds and retrofits in industrial automation environments. Feature: 6 in height and 18 in width with 37 in length provide precise enclosure fitment. Benefit: Predictable planning and straightforward cut-in calculations for rack-mount or wall-mounted systems. Application: Shop floors, control rooms, and electrical rooms where exact dimensions are critical. Industry context: Lightweight aluminum geometry supports faster commissioning and lower total installed cost for cable management projects.

Get a Quick Quote for a Eaton 6A-18-45HB36

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-18-45HB36?

Enquire Now

FAQs

Yes. The 6A-18-45HB36 is designed as a horizontal bend within the Eaton B-Line series, ensuring direct compatibility with aluminum B-Line cable tray sections and standard mounting channels. Its 37 in length and 6 in height with an 18 in width align with common B-Line layouts, simplifying field fabrication and reducing mismatch risk during retrofits.

The bend features a 36 in radius and a 45° angle, providing a smooth directional change with fewer fittings. The aluminum construction yields a lightweight component (12.4 lb) suitable for overhead and wall-mounted cable tray runs, while maintaining structural integrity for steady, long-term operation.

Absolutely. The 36 in radius 45° bend is well-suited for data centers, control rooms, and manufacturing floors where space constraints and consistent cable routing are critical. Its aluminum body reduces weight for overhead installations, and the 37 in length helps cover substantial routing distances without excessive fittings.

This Eaton B-Line bend carries CSA, UL Classified, and CE certifications, supporting regulatory compliance in North America and Europe. These certifications provide documented assurance for electrical safety, material quality, and product performance in industrial environments.

The Bend’s aluminum construction combined with its standardized dimensions reduces field labor and retrofit time, lowering installation costs. Fewer joints mean fewer potential failure points, easier inspections, and improved system reliability, delivering a favorable return on investment over the life of the cable tray system.