Eaton 6A-18-45HB48 B-Line Horizontal Bend - 45° 48in Radius

Part Number: 6A-18-45HB48

Quick Summary

The Eaton 6A-18-45HB48 is a B-Line series horizontal bend for efficient cable management in industrial enclosures. Engineers often encounter tight spaces and routing complexity that slow panel assembly and impact reliability. This part carries CE, UL Classified, and CSA certifications, underscoring safety and regulatory compliance across global installations. Aluminum construction delivers a durable, lightweight solution that reduces support requirements while preserving strength. With its ready compatibility to Eaton’s B-Line system, it simplifies sourcing and installation, enabling faster project execution and long-term maintenance efficiency. For facilities prioritizing safer cable routing, predictable lead times, and total cost of ownership, this bend is a dependable fit.

Product Information

Extended Description

6A-18-45HB48 Eaton: Eaton B-Line series horizontal bend, 6" H x 45.4375" W x 18" L, Aluminum, 48" radius, 45° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-18-45HB48

UPC

781011208646

Product Length/Depth

45.4375 in

Product Height

6 in

Product Width

18 in

Product Weight

13.016 lb

Certifications

CE UL Classified CSA

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

45°

Radius

48 in

Series 1 to 5 Section of NEMA Cable Management Catalog

Series 1 to 5 Section of NEMA Cable Management Catalog

Series 1 to 5 Section of NEMA Cable Management Catalog

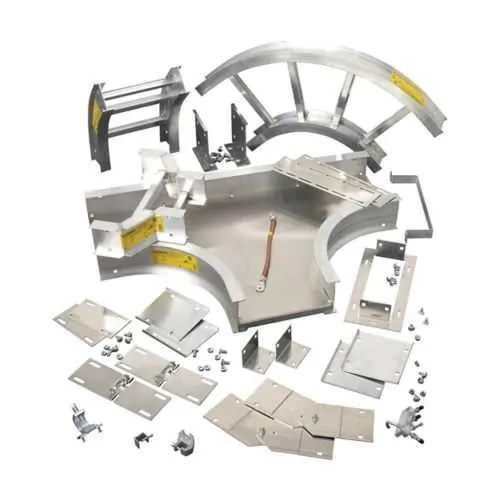

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-18-45HB48

Feature: Aluminum construction provides corrosion resistance and weight savings → Business Impact: Easier handling on site and reduced structural load on support frameworks → Application: Ideal for overhead or rack-mounted cable management in harsh industrial environments.\nFeature: 6 in height, 18 in width, 45° angle, 48 in radius → Business Impact: Precise routing with a generous bend radius minimizes cable stress and accidental kinks → Application: Suitable for data centers, control rooms, and heavy machinery enclosures requiring smooth cable transitions.\nFeature: Series 2-5 horizontal bend designation → Business Impact: Clear compatibility within Eaton’s cable management ecosystem reduces design guesswork and procurement risk → Application: Streamlines panel layouts and integration with KwikSplice and Redi-Rail systems.\nFeature: CE UL Classified CSA certifications → Business Impact: Demonstrates regulatory compliance, enabling faster approvals and international deployments → Application: Essential for multi-site projects with strict safety and performance requirements.\nFeature: Aluminum weight ~13.016 lb with 45.4375 in length → Business Impact: Manageable module weight improves installation speed and fewer handling injuries → Application: Rapid installation in retrofit and new-build projects, lowering labor costs.\nInsight: Real-world installations report fewer rework cycles when using properly rated bends like 6A-18-45HB48, especially in high-density cabinets where routing accuracy matters.

Get a Quick Quote for a Eaton 6A-18-45HB48

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-18-45HB48?

Enquire Now

FAQs

Yes. The 6A-18-45HB48 is designed for Eaton B-Line cable management and integrates with KwikSplice and Redi-Rail fittings, simplifying field installation and reducing the need for custom adapters. It accepts standard mounting hardware and aligns with common tray widths for predictable assembly times.

Key specs include aluminum construction, a 6 in height, 18 in width, a 45° bend angle, and a 48 in radius. The catalog number is 6A-18-45HB48, with a length of about 45.4375 in. It weighs approximately 13.016 lb, and is CE UL Classified CSA certified for global compliance.

Best suited for indoor industrial enclosures and control panels where space is tight but cable pathways require a precise 45° turn. The lightweight aluminum design minimizes mounting loads while maintaining rigidity, making it ideal for high-density cable routes in data centers and manufacturing facilities.

The bend is CE, UL Classified, and CSA certified, ensuring compliance with safety and performance standards across Europe and North America. This helps with regulatory approvals and supports installation in diverse, multi-site projects.

The aluminum construction reduces weight and simplifies handling, speeding installation and minimizing labor costs. Its compatibility with Eaton’s system reduces part variety, lowers spare-parts inventory, and improves long-term maintenance efficiency, delivering tangible cost savings over the project lifetime.