Eaton 6A-18-60HB12 Horizontal Bend - CE/UL/CSA

Part Number: 6A-18-60HB12

Quick Summary

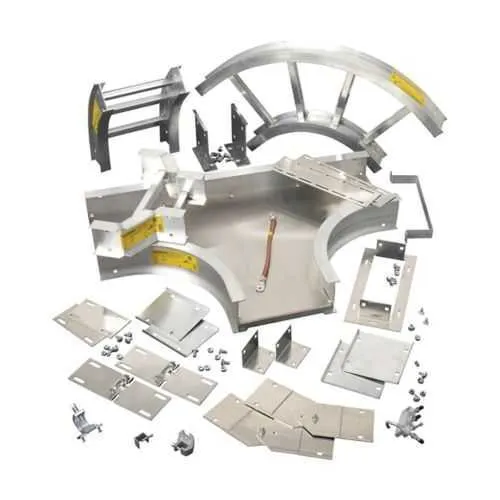

The Eaton B-Line series horizontal bend directs cable trays around corners in industrial electrical installations. Misalignment and limited clearance commonly slow projects, jeopardizing schedule and safety. This bend is CE certified, UL Classified, and CSA listed, with a 60° angle and a 12 in radius to deliver precise routing. Made from aluminum for a lightweight yet durable solution, it supports quick installation and consistent performance across harsh environments. The 22.75 in long by 18 in wide footprint, and a 7.6 lb weight, balance reach with handling ease, helping crews deploy trays without excessive fabrication. Selecting this bend improves installation accuracy, regulatory compliance, and overall system reliability for data centers, factories, and workflow areas.

Product Information

Extended Description

6A-18-60HB12 Eaton: Eaton B-Line series horizontal bend, 6" H x 22.75" W x 18" L, Aluminum, 12" radius, 60° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-18-60HB12

UPC

781011208578

Product Length/Depth

22.75 in

Product Height

6 in

Product Width

18 in

Product Weight

7.6 lb

Certifications

CE UL Classified CSA

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

60°

Radius

12 in

Cable tray and Cable Management NEMA Catalog

Cable tray and Cable Management NEMA Catalog

Cable tray and Cable Management NEMA Catalog

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-18-60HB12

Aluminum construction delivers corrosion resistance and a favorable strength-to-weight ratio, reducing the load on support structures while simplifying handling during installation. In demanding environments such as manufacturing floors or chemical-adjacent areas, this material choice translates to longer service life and lower replacement costs, even with frequent access and maintenance. The 60° bend with a 12 inch radius supports smooth cable tray routing around equipment and corners, minimizing tray flex and reducing the risk of cable damage. This precise geometry helps maintain consistent tray spacing and reduces the need for corrective field bends, saving installation time and improving electrical performance in data centers and production lines. With a footprint of 22.75 in length, 18 in width, and 6 in height, this bend fits standard tray configurations and works with multiple tray depths. The universal aluminum design complements KwikSplice and Redi-Rail fittings, accelerating integration with existing cable-management systems. At 7.6 lb, the part is easy to maneuver, reducing labor during installation and transport on site. CE UL CSA certifications provide compliance assurance for regulated facilities, and the included UPC and catalog references streamline procurement and traceability.

Get a Quick Quote for a Eaton 6A-18-60HB12

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-18-60HB12?

Enquire Now

FAQs

Plan for a 60° turn with a 12 in radius to maintain consistent tray spacing and minimize flex. Verify clearance around nearby equipment and support structures, ensure compatibility with existing KwikSplice or Redi-Rail fittings, and confirm tray width matches the 18 in footprint. The aluminum construction aids handling and reduces on-site weight when maneuvering into position.

A 12 in radius provides a gradual bend that reduces cable bending stress and tray deformation, improving airflow and cable organization. In compact enclosures or crowded racks, this radius helps maintain clean routing without requiring additional field bends, shortening installation time and lowering risk of crosstalk or insulation damage.

The 6A-18-60HB12 is designed for aluminum cable-tray systems in many installations and aligns with standard B-Line series fittings. For steel trays, verify load ratings and compatible mounting hardware with Eaton catalogs. In most applications, the aluminum bend integrates smoothly with compatible tray materials, reducing mismatch and installation complexity.

This bend carries CE, UL Classified, and CSA certifications, which support compliance with European, U.S., and Canadian safety and performance standards. Certification implies conformity to material, electrical, and mechanical requirements, helping facilities meet procurement and installation regulations and reducing audit risk.

The lightweight aluminum design, precise 60° geometry, and standard footprint reduce field fabrication and labor costs. Certification-backed reliability lowers maintenance calls and rework, while predictable routing improves overall system uptime in manufacturing floors, data centers, and industrial plants, delivering measurable efficiency and total-cost-of-ownership benefits.