Eaton 6A-18-90HB36 Horizontal Bend - CSA UL CE

Part Number: 6A-18-90HB36

Quick Summary

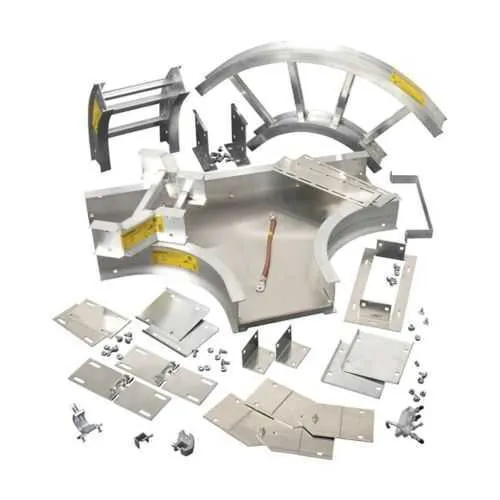

The Eaton B-Line series horizontal bend guides cable tray runs around corners in industrial electrical installations. It minimizes field bending errors, reduces installation time, and protects trays in tight spaces. This part carries CSA, UL Classified, and CE certifications, ensuring compliance across North American and international projects. With aluminum construction and a 36 in radius, it delivers a lightweight, durable solution that supports larger cable loads and smoother system integration. Designed for seamless integration with the B-Line family and associated fittings, it pairs with KwikSplice systems to simplify inventory, installation, and maintenance. For engineers, procurement, and installers, the result is a scalable, compliant cable-management solution that lowers total installed cost and enhances reliability.

Product Information

Extended Description

6A-18-90HB36 Eaton: Eaton B-Line series horizontal bend, 6" H x 48.0625" W x 18" L, Aluminum, 36" radius, 90° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-18-90HB36

UPC

781011208684

Product Length/Depth

48.0625 in

Product Height

6 in

Product Width

18 in

Product Weight

22.2 lb

Certifications

CSA UL Classified CE

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

90°

Radius

36 in

Cable tray and Cable Management NEMA Catalog

Cable tray and Cable Management NEMA Catalog

Cable tray and Cable Management NEMA Catalog

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-18-90HB36

Feature: Aluminum construction provides corrosion resistance and lightweight handling. Business Impact: Reduces long-term maintenance costs and installation effort, improving site safety and efficiency. Application: Ideal for indoor and outdoor cable tray runs in industrial environments. Feature: 36 inch radius and 90° angle for the bend. Business Impact: Allows larger routing curves with fewer intermediate fittings, cutting assembly time and potential misalignment. Application: Suitable for dense wiring zones and equipment rooms where space is at a premium. Feature: Cataloged dimensions and weight (48.0625 in length, 6 in height, 18 in width; 22.2 lb). Business Impact: Predictable fit within existing trenching and support structures, enabling faster design loading and accurate material ordering. Application: Streamlines project planning for large-scale installations. Feature: Certifications CSA, UL Classified, CE. Business Impact: Ensures regulatory compliance across jurisdictions, reducing risk of rework and acceptance delays. Application: Critical for multinational projects and safety-conscious facilities. Feature: Compatibility with Eaton B-Line system and KwikSplice/Redi-Rail fittings. Business Impact: Simplifies installation sequences, minimizes field adjustments, and improves retrofit capability. Application: Ideal for modular data centers, manufacturing lines, and utility enclosures. Feature: Ready-to-use horizontal bend for cable management. Business Impact: Accelerates project timelines and provides repeatable performance across multiple runs. Application: Commonly deployed in rack rows, cable trays, and enclosure footprints.

Get a Quick Quote for a Eaton 6A-18-90HB36

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-18-90HB36?

Enquire Now

FAQs

The 6A-18-90HB36 is a direct compatible horizontal bend designed for Eaton B-Line cable tray systems. Its 36 in radius and 90° angle match standard B-Line configurations, enabling seamless integration with existing trays and supports. It pairs with Eaton KwikSplice fittings and Redi-Rail universal fittings to minimize field adjustments and ensure alignment with adjacent segments.

The bend carries CSA certification, UL Classified, and CE marking, covering North American safety and international market requirements. These certifications help ensure regulatory compliance, safer installations, and smoother project approvals for both new builds and retrofits.

This bend excels in industrial facilities, data centers, and manufacturing environments where cable trays must navigate tight corners. Its aluminum construction and 36 in radius support high cable volumes with reduced bending complexity, while the 48.0625 in length fits standard rack and enclosure footprints without excessive protrusion.

Plan for a 90° turn with a 36 in radius and ensure the bend aligns with the existing tray width (18 in) and height (6 in). Use compatible Eaton fittings (KwikSplice, Redi-Rail) to minimize field modifications and verify weight allowance, as the unit weighs 22.2 lb per piece, which influences support requirements and handling procedures.

By reducing field bending, cutting, and rework, the bend lowers labor time and risk of misalignment. Its standardized dimensions and compatibility with the B-Line ecosystem simplify procurement and maintenance, delivering faster installs, easier replacements, and a lower total cost of ownership over the system’s life cycle.