Eaton 6A-24-15HB24 Horizontal Bend - 24in Radius CSA/CE/UL

Part Number: 6A-24-15HB24

Quick Summary

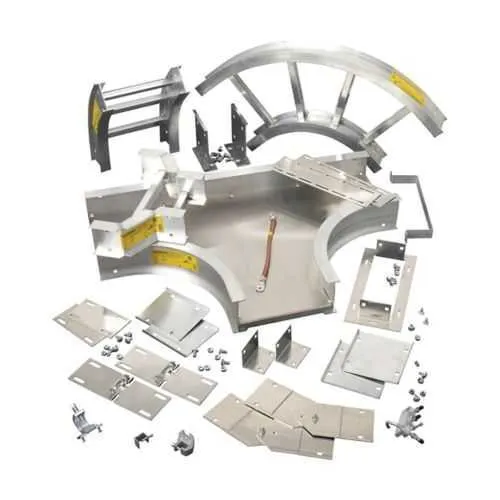

The Eaton B-Line horizontal bend routes cables in industrial electrical installations with a rugged aluminum build. It addresses pain points like tangled trays and time-consuming field bends by delivering a precise 24-inch radius and 15-degree angle. Certified CSA, CE, and UL Classified, this bend supports compliance in heavy-industrial and commercial installations. With aluminum construction and a compact footprint, it enhances installation efficiency and long-term durability for cable-management teams. Designed for Series 2-5 horizontal bends, it's compatible with common fittings and supports consistent routing across NEMA trays. In practice, teams report faster installs, fewer field cuts, and improved cable strain relief when using the 6A-24-15HB24.

Product Information

Extended Description

6A-24-15HB24 Eaton: Eaton B-Line series horizontal bend, 6" H x 14.28" W x 24" L, Aluminum, 24" radius, 15° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-24-15HB24

UPC

781011210243

Product Length/Depth

14.28 in

Product Height

6 in

Product Width

24 in

Product Weight

4.271 lb

Certifications

CSA CE UL Classified

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

15°

Radius

24 in

Series 1 to 5 Section of NEMA Cable Management Catalog

Series 1 to 5 Section of NEMA Cable Management Catalog

Series 1 to 5 Section of NEMA Cable Management Catalog

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-24-15HB24

Feature: Aluminum construction with a weight of 4.271 lb and a 24 in radius. Business impact: Lighter components reduce handling risk, ease installation, and lower overall labor costs while maintaining structural integrity. Application: Ideal for long cable runs in manufacturing floors or data centers where weight limits and routing precision matter. Feature: 15° bend angle with a 14.28 in length and 6 in height, 24 in width. Business impact: Predictable geometry ensures clean cable paths, reduces the need for additional fittings, and speeds commissioning. Application: Used at corners or transitions in service entrance areas and equipment rooms. Feature: CSA CE UL Classified certifications. Business impact: Supports regulatory compliance and reduces risk during audits, improving safety and liability profile. Application: Meets common electrical codes for industrial facilities. Feature: Series 2-5 horizontal bend type. Business impact: Ensures compatibility across Eaton’s cable-management ecosystem, simplifying procurement. Application: Works with Series 1–5 aluminum tray sections and compatible accessories for scalable installations. Feature: Catalog number 6A-24-15HB24 with 24in radius. Business impact: Clear part identification accelerates sourcing, reduces RFQ cycles, and stabilizes project schedules. Application: Suitable for mid-span and corner transitions in industrial cable trays.

Get a Quick Quote for a Eaton 6A-24-15HB24

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-24-15HB24?

Enquire Now

FAQs

Yes. The 6A-24-15HB24 is designed as a Series 2-5 horizontal bend and is compatible with Eaton B-Line Series aluminum cable-tray sections. Its 24 in radius and 15° angle provide consistent routing, and it works with standard Eaton fittings, KwikSplice systems, and Redi-Rail universal fittings, enabling scalable, code-compliant installations across partial or full tray runs.

The bend has a length (depth) of 14.28 in, a height of 6 in, and a width of 24 in, with a radius of 24 in and an angle of 15°. It weighs 4.271 lb, delivering a balance of strength and manageability for field installation and handling within standard tray spans and mounting provisions.

This bend carries CSA, CE, and UL Classified certifications. These approvals support compliance with regional electrical codes and safety standards, reducing project risk in industrial facilities and helping expedite audits and field inspections for cable-management systems.

Aluminum provides corrosion resistance and a favorable strength-to-weight ratio, improving long-term durability while simplifying handling and installation. In harsh environments, aluminum resists rust that can compromise cable pathways, contributing to lower maintenance intervals and fewer reworks due to material degradation.

By enabling precise routing with a single pre-formed bend, this part reduces the need for multiple elbows and fittings, cutting procurement complexity and labor time. The result is faster project completion, predictable material usage, improved cable strain relief, and a lower total cost of ownership over the life of the cable-management system.