Eaton 6A-24-30HB24 Horizontal Bend - CE UL CSA

Part Number: 6A-24-30HB24

Quick Summary

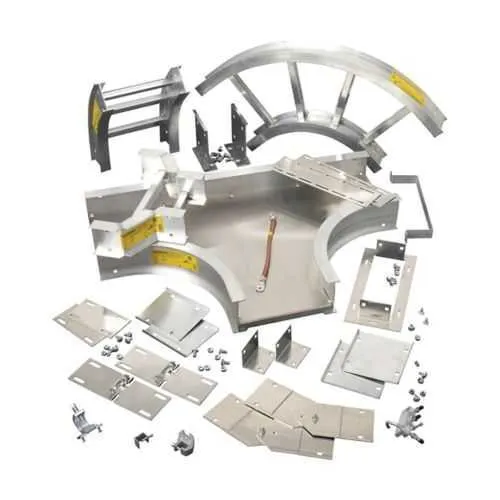

Eaton 6A-24-30HB24 horizontal bend guides cable trays through 30° corners in industrial racking. It addresses alignment and spacing challenges that slow installations in crowded enclosures. With CE, UL Classified, and CSA certifications, it meets global safety and performance standards for electrical and data installations. Made from aluminum for durable corrosion resistance, it integrates with Eaton B-Line cable tray systems to accelerate installs and reduce lifecycle costs. Designed for the Eaton B-Line Series, this 6 in high, 24 in wide bend accommodates a 24 in radius to maintain consistent routing. At only 6.9 lb, it enables straightforward field adjustments and reduces labor time.

Product Information

Extended Description

6A-24-30HB24 Eaton: Eaton B-Line series horizontal bend, 6" H x 23.6250" W x 24" L, Aluminum, 24" radius, 30° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-24-30HB24

UPC

781011209476

Product Length/Depth

23.625 in

Product Height

6 in

Product Width

24 in

Product Weight

6.9 lb

Certifications

CE UL Classified CSA

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

30°

Radius

24 in

Cable tray and Cable Management NEMA Catalog

Cable tray and Cable Management NEMA Catalog

Cable tray and Cable Management NEMA Catalog

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-24-30HB24

Feature → Aluminum construction delivers strength with lightweight handling, easing field installation. Business Impact → This reduces labor time and tool wear, improving ROI on busy job sites; Application → Ideal for ceiling runs and dense enclosures in industrial plants. Feature → The 30° bend with a 24 in radius delivers precise geometry for reliable cable routing. Business Impact → Maintains linear paths, reduces tray sag, and minimizes rework in expanding industrial layouts; Application → Works well in long cable tray runs across machine bays and data centers. Feature → CE, UL Classified, and CSA certifications verify compliance and safety. Business Impact → Helps pass audits and reduces regulatory risk; Application → Essential for facilities with strict electrical codes and safety standards. Feature → Integrates with Eaton B-Line Series cable tray systems. Business Impact → Streamlines procurement and reduces compatibility risk; Application → Suitable for integrated layouts that require consistent accessories across the line. Feature → Aluminum construction with compact dimensions of 6 in height and 24 in width, weighing 6.9 lb. Business Impact → Improves handling and reduces installation effort, supporting retrofits in congested spaces; Application → Ideal for retrofit projects and new builds in constrained environments.

Get a Quick Quote for a Eaton 6A-24-30HB24

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-24-30HB24?

Enquire Now

FAQs

The 6A-24-30HB24 is designed as a B-Line Series horizontal bend, ensuring seamless integration with Eaton’s cable tray accessories. It matches the Series 2-5 horizontal bend class and uses standard dimensions and mounting conventions common to the B-Line lineup. This compatibility reduces procurement risk and simplifies on-site assembly, particularly for mid-sized or expanding facilities that rely on Eaton’s standardized cable management ecosystem.

Important specifications include catalog number 6A-24-30HB24, material aluminum, radius 24 in, angle 30°, height 6 in, width 24 in, length 23.625 in, weight 6.9 lb, and certifications CE, UL Classified, CSA. The bend is intended for use with Eaton B-Line cable tray systems and provides a 30° corner with a 24 in radius to maintain consistent routing in limited spaces.

Yes. The aluminum construction offers corrosion resistance and durability while the 24 in radius and 30° angle provide predictable geometry for dense cable layouts. With a weight of 6.9 lb, it remains manageable for field installs, and its compatibility with B-Line series trays helps maintain clean, scalable pathways in data centers and manufacturing floors.

The bend carries CE, UL Classified, and CSA certifications. These indicate compliance with European, North American safety and performance standards, which simplifies audits, reduces regulatory risk, and supports safer installations in regulated facilities such as industrial plants and data centers.

Aluminum construction minimizes corrosion-related maintenance and extends service life, while the precise bend geometry reduces rework and installation time. The result is lower lifecycle costs and a faster return on investment, especially in retrofit projects or facilities undergoing frequent upgrades to cable tray layouts.