Eaton 6A-24-30HB48 Horizontal Bend - UL 48in Radius

Part Number: 6A-24-30HB48

Quick Summary

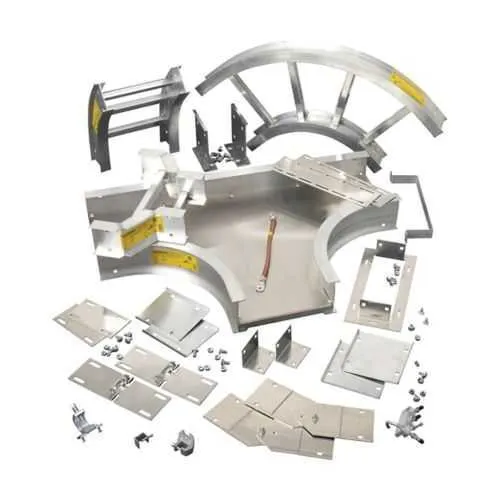

The Eaton B-Line series horizontal bend 6A-24-30HB48 is a durable elbow used to route aluminum cable trays around corners in electrical installations. Engineers often struggle with misaligned runs and cable compression when turning long spans; this bend provides a precise 30° angle and a generous 48-in radius to minimize bend-induced impedance and cabling wear. UL Classified, CE, and CSA certifications, plus industry-standard aluminum construction, ensure safety, compatibility, and regulatory compliance across facilities. Designed for easy integration with KwikSplice cable tray systems and Redi-Rail universal fittings, it supports fast installation and reduces field adjustments. With standard dimensions and a clear Eaton part number, procurement, inventory management, and maintenance planning stay straightforward, helping projects stay on schedule and on budget.

Product Information

Extended Description

6A-24-30HB48 Eaton: Eaton B-Line series horizontal bend, 6" H x 35.6250" W x 24" L, Aluminum, 48" radius, 30° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-24-30HB48

UPC

781011209469

Product Length/Depth

35.625 in

Product Height

6 in

Product Width

24 in

Product Weight

10.7 lb

Certifications

UL Classified CE CSA

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

30°

Radius

48 in

Cable tray and Cable Management NEMA Catalog

Cable tray and Cable Management NEMA Catalog

Cable tray and Cable Management NEMA Catalog

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-24-30HB48

Aluminum construction enables lightweight handling and corrosion resistance, reducing labor strain during installation and improving durability in harsh environments. This translates to lower on-site fatigue and long-term maintenance costs, especially on multi-bend runs in manufacturing plants. The 30° bend with a 48in radius reduces cable stress and impedance, improving data integrity and power delivery for trays carrying mixed cabling in data centers and automation facilities. Dimensions of 6in height, 24in width, and 35.625in length fit standard tray footprints, while a weight of 10.7lb keeps support structures within typical load limits, facilitating straightforward installation. UL Classified, CE, and CSA certifications provide compliance assurance for regulated environments and multisite deployments. Compatibility with KwikSplice and Redi-Rail universal fittings enables faster, tool-free field assembly and reduces the need for custom angles. The design also supports scalable installations, helping to standardize inventory and procurement across projects and facilities. Industry practitioners appreciate the clear Eaton cataloging and readily available specification sheets, which streamline approvals, quality checks, and maintenance planning.

Get a Quick Quote for a Eaton 6A-24-30HB48

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-24-30HB48?

Enquire Now

FAQs

The 6A-24-30HB48 is designed for seamless integration with KwikSplice cable tray systems and Redi-Rail universal fittings. Begin by verifying tray width and height alignment, then place the bend at the desired corner, securing with standard fasteners per the installation instructions. Use the Eaton specification sheet as a reference for compatible fittings and ensure UL Classified, CE, and CSA compliance during mounting to maintain system integrity and warranty validity.

Key specs include a 30° bend, 48 in radius, and aluminum construction. The unit measures 6 in in height, 24 in in width, and 35.625 in in length, with a weight of 10.7 lb. The catalog number is 6A-24-30HB48 and the UPC is 781011209469, with UL Classified, CE, and CSA certifications supporting compliance.

Yes. The bend is UL Classified and carries CE and CSA certifications, ensuring compliance with safety, performance, and regulatory standards across many industrial facilities. Its aluminum construction further enhances durability in harsh environments, making it suitable for plants, data centers, and assembly lines that require certified cable management components.

Applications with tight corners and dense cable runs benefit most, including data centers, manufacturing floors, and electrical rooms. The 30° bend minimizes bend-induced stress while the 48in radius supports smoother cable routing, reducing impedance and wear on power and data cables in high-density installations.

This bend addresses challenges such as misaligned trays, excessive field cutting, and inconsistent bend radii. Its standardized 30° angle and 48in radius promote repeatable installations, speeding up project timelines and reducing labor cost. Compliance certifications and compatibility with existing KwikSplice/Redi-Rail systems improve reliability, reduce change orders, and support predictable maintenance budgets.