Eaton 6A-24-45HB36 Horizontal Bend - UL Classified Aluminum

Part Number: 6A-24-45HB36

Quick Summary

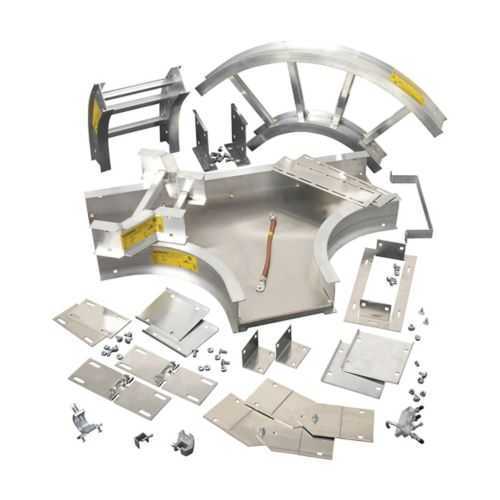

Eaton 6A-24-45HB36 horizontal bend is a precision component for routing aluminum cable tray systems in industrial facilities. Engineers often struggle with fitment and misalignment when building curved sections, leading to rework and project delays. UL Classified, CE, and CSA certifications help ensure electrical safety, regulatory compliance, and dependable performance in demanding environments. Designed for B-Line series installations, this bend complements other aluminum fittings and supports faster, error-free assemblies while reducing total installed cost.

Product Information

Extended Description

6A-24-45HB36 Eaton: Eaton B-Line series horizontal bend, 6" H x 39.1250" W x 24" L, Aluminum, 36" radius, 45° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-24-45HB36

UPC

781011209537

Product Length/Depth

39.125 in

Product Height

6 in

Product Width

24 in

Product Weight

14.5 lb

Certifications

UL Classified CE CSA

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

45°

Radius

36 in

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-24-45HB36

Feature: Aluminum construction provides corrosion resistance and a lighter profile, lowering handling effort during installation and reducing freight costs. Business impact: Improves durability in harsh environments and simplifies on-site assembly for busy electrical trades. Application: Ideal for metal cable tray systems in manufacturing floors and data centers where weight and corrosion resistance matter. Feature: 36 in radius with a 45° bend enables smooth cable routing through constrained spaces, minimizing tight bends and cable wear. Business impact: Reduces the need for multiple fittings and rework, shortening installation time. Application: Suitable for long-radius runs in ladder-type cable tray networks in machine rooms and process areas. Feature: 39.125 in length, 6 in height, 24 in width, and 14.5 lb weight deliver a predictable footprint within standard tray layouts. Business impact: Predictable geometry enhances layout planning and inventory management. Application: Works with common 24 in wide trays and supports consistent module spacing in new builds and retrofits. Feature: UL Classified, CE, CSA certifications verify compliance with electrical and safety standards. Business impact: Enables acceptance by regulated facilities and simplifies audit trails. Application: Critical for aerospace, data centers, and process industries requiring formal conformity. Feature: Documentation and compatibility resources provide fast referencing and correct installation. Business impact: Reduces commissioning risk and accelerates procurement cycles. Application: Integrates with KwikSplice system manuals and Eaton cable management catalogs for streamlined projects.

Get a Quick Quote for a Eaton 6A-24-45HB36

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-24-45HB36?

Enquire Now

FAQs

For proper installation, align the bend with standard B-Line series trays, confirm aluminum compatibility, and verify the 39.125 in length, 6 in height, and 24 in width fit the layout. Use typical fasteners and follow Eaton documentation. The 36 in radius and 45° angle support smooth routing while reducing need for extra fittings, saving time and labor.

Yes. Eaton provides installation instructions and references related to KwikSplice Cable Tray System compatibility. This bend is designed to integrate with Redi-Rail and KwikSplice configurations, simplifying universal fitting assemblies and accelerating on-site setup while maintaining the B-Line series performance.

The bend is UL Classified, CE marked, and CSA certified. These certifications confirm compliance with electrical, safety, and performance standards, facilitating approval in regulated facilities, improving audit readiness, and reducing risk for critical applications such as data centers and process industries.

Ideal for industrial facilities, manufacturing floors, and data centers that rely on aluminum cable tray systems. The 36 in radius and 45° angle support long, smooth routing around equipment, while the aluminum construction offers corrosion resistance and easier handling during retrofit projects.

Key specs include aluminum construction (durability and lower weight), 36 in radius (reduced part count and fewer misalignments), 39.125 in length with 6 in height and 24 in width (predictable footprint for planning), and 14.5 lb weight (ease of installation). Together with UL CE CSA certifications, they lower maintenance, downtime, and lifecycle costs.